Tap Cone/ Tap Out Cone For Metal Melting Furnaces

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

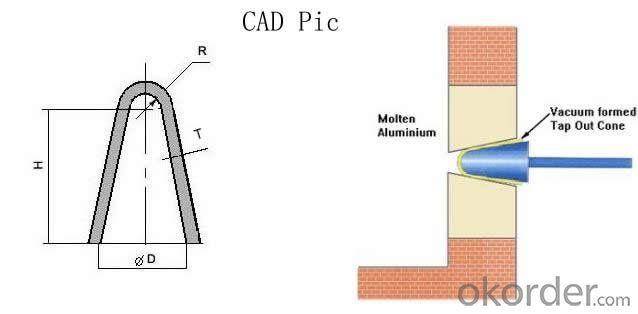

Metal Melting Furnace Tap Cone / Tap Out Cone

Product Description:

Aluminum Silicate Tap Out Cones, also called insulated plugs, are insulated hats and insulated core plugs. They are mainly made by senior aluminum silicate fiber and other formulas through vacuum forming. It is widely used for insulating in aluminum smelting furnaces, refineries, static furnaces and furnace outlets. Making the aluminum and aluminum alloy casting process more convenient, more reliable and much safer.

Product Features:

• Excellent thermal shock resistance

• No infiltration with the non-ferrous metal

• Excellent wear resistance

• Low thermal-expansion coefficient

• Long service life

Product Specifications:

Aluminum Silicate Riser Sleeve:

Form A | |||||||

Working Temperature | Density | Bending Intensity | Pressure Resistance Intensity | Coefficient of Heat Conductivity | Heat Linear Shrinkage | Coefficient of Heat Expansion | |

oC | g/cm³ | MPa | MPa | 720ºC (w/m·k) | 800ºC (%) | 700ºC (×10-6ºC) | |

≥800 | 0.5-0.6 | ≥0.25 | ≥0.35 | 0.12W/m.k | ≤0.5 | ≤2.77 | |

Form B | |||||||

SiO₂ | AL₂O₃ | Fe₂O₃ | CaO | Dregginess | TiO₃ | Fe₂O₃ | Na₂O |

48.5% | 50.4% | 0.14 | 0.41 | ≤0.05% | 0.7% | 0.3% | 1.0% |

Product Packaging:

Packaging Details: 1) Polyfoam filled, wooden box 2) As requested based on the order.

Delivery Details: Air/Sea, 15 days after receiving payment

Product Images:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What other products does OKorder offer?

A3: We offer a full range of refractory bricks, mortar, cement, ceramic fiber products, and more.

Q4: Where are Ceramic Fiber products used?

A4: Ceramic fiber products have many advantages, including: high temperature stability, lightweight, superior insulation, and ease of application. Fiber products are available in a variety of product forms to solve a range of thermal management application problems across various industries. The main industrial market segments that use ceramic fiber and soluble fiber products are the aluminum, iron, steel, heat treatment, power, incineration, boilers, and glass industries.

Q5: What kind of Ceramic Fiber should I use?

A5: When selecting the fiber type for a particular application, it is important to consider all factors. If the fiber/fabric will not have to support a load at temperature, the lower-cost industrial grade fibers may be appropriate. However, if the fiber will be load bearing at temperature as in ceramic matrix composites, then one of the composite grade fibers would be a better choice. Of course there may be other factors, such as corrosion, chemical resistance, or atmospheric conditions that may require trade-off in the selection process.

Q6: What`s the lead time for my order?

A6: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q7: Can you offer Door-to-Door delivery?

A7: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q8: What is the minimum quantity?

A8: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Send your message to us

Tap Cone/ Tap Out Cone For Metal Melting Furnaces

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords