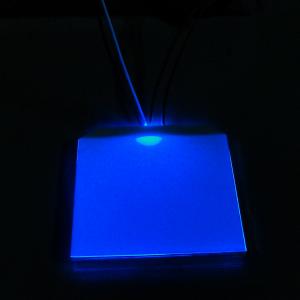

Superslim RGB LED Backlight

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 500 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Feature

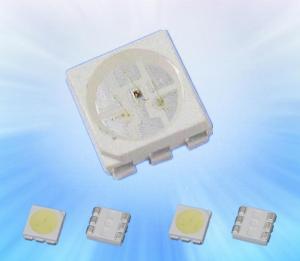

Using ultra higher brightness SMD0603 led.

Three colors available for one led backlight.

PCB with pins for convenient assebly and soldering to the main PCB.

Good uniformity and consistency.

Lower power consumption and long lifespan.

Our Services

1-Customized logo is acceptable

2-Changing the shape, color is acceptable

3-Develop on artwork & development is acceptable

4-Assistant on artwork development is acceptable

Before Orders

If possible, please tell us what's the purpose for using it, so that we can recommend you the best package. Of course with best price to you!

Any other request, please feel free to let us know.

SAMPLES are avaiable before order.

OEM & ODM service is also avaiable

Our R&D department have more than 20 professional and technical personnel.We had help customers produce many OEM products for American Market,Germany Market and UK Market.

QC(Quality Control)

QC Team:More than 20 professional and technical personnel.

Material: Strictly control of material using, meet international requested standards.

Semi-finished Products Inspection: Product inspection before 100% finished. Such as Visual Inspection, Leak Testing, Comprehensive Safty Test and so on.

Production Line Test: With work team or data engineer who will inspect machines and lines at fixed period.

Finished Product Inspection: Quality and property test before products are packed and loaded

Packaging & Delivery

Package:

Using suitable carton package as per goods situations.

Shipping via express,air or sea as per customer's requires.

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By sea | 30-40 business days |

1. 3-10 business days for Sample Orders; 7-40 business days for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address.

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q: Production of a number of substrates, the use of SMD LED lights, red lights and green lights are not bad, blue lights appear mass dark, do not know why? Is the LED blue light material easy to use dark?

- The pressure drop of the blue light is greater than that of the red light and the green light. If the series connection is the same as that of the green light and red light, the current limiting resistor will tend to dim

- Q: What is the principle used in SMD LED lamp, should pay attention to what the problem?

- LED installation method 1, don't install the LED pin in 2, under the condition of deformation in printed circuit board when installing LED, circuit board hole center distance and LED pin center spacing should be the same, if the hole spacing will make the lamp feet have residual stress and welding...

- Q: What is the difference between SMT LED packaging with silicone and epoxy resin transparent package? What is the market situation of these two types of packaging?

- Epoxy resins turn yellow during short wave irradiation or long periods of high temperature, so they are very short lived when applied to high power lighting. That's why the LED lighting market is dominated by silica gel.But because of the low price of epoxy resin (silica gel and not at a level), and storage, use and processing is superior to silica gel, so the low power LED and some optical components still use epoxy resin package.

- Q: LED patches have several ways of welding. Which ones can be reflow? What can be done by eutectic welding? Is the welding of viscose and lens material is required?

- SMD patch products basically can be used in reflow soldering, especially a little note here that the eutectic welding is the connection between the chip and the substrate support or specifically, is the bottom of the chip after completion of production of coating material and a layer of Sikkim alloy, and then set up a heating zone in solid crystal machine package in time and a temperature of about 300 degrees, the realization process of the chip at the bottom of the Sikkim alloy melt and silver plated layer connection bracket, and a clear distinction between reflow.

- Q: Patch LED features

- The principle of luminescence is that of cold luminescence, not by heating or discharging light, so the component life is about 50~100 times longer than that of tungsten filament bulb, and about one hundred thousand hours.

- Q: What is patch LED?

- Patch element. Very small, no pins, soldered directly to the circuit board. For example, the keyboard lights in a mobile phone are used in this way.

- Q: LED package and LED SMD LED lamp, what is the difference? Will the release agent be used in that part?

- Packaging is for TOP series LED, that is, the type of plastic molding. The patch is based on the PCB circuit board for molding. Mold release agent is used in molding.

- Q: Patch LED light broken one, short circuit can use it?

- Patch LED lamp LED wick is usually series, and a bad, can temporarily short-circuit, temporary use, because after short-circuit, this LED wick voltage will be assessed to other LED wick, accelerate other LED wick aging.The damaged LED wick needs to be secured as soon as possible.

- Q: How do led patches measure good or bad?

- LED patch how to measure methods: use two meter meter test, red pen is positive, black pen negative, if there is "bee" sound is bad, if the light is good

- Q: Such as title, please have welding patch LED lamp experience expert guidance, do not search from the Internet to the theoretical knowledge, thank you!

- Recommend to communicate with older employees, they will have a lot of welding experience

Send your message to us

Superslim RGB LED Backlight

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 500 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches