Superfine Grade Barite Powder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 3000 Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stable supply of Barite and FACTORY PRICE

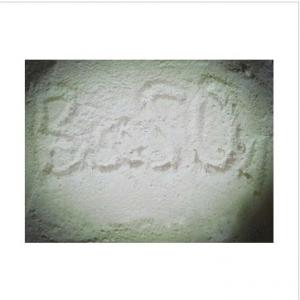

Content (BaSO4) : 97%-98%

Specific Gravity : 4.2-4.4 min

Particle Size : 3000 mesh

Time delivery

Other trace elements meet the international standard

We can supplyoil drilling barite, chemical barite ,white barite for paint and coating.

You can enjoythe factory priceand high quality barite powder. Our barite can meet all your requirements andthe other trace elements can meet the international standard.

Applications:

1. As raw material for paints, printing ink, plastics, rubber and storage battery.

2. As surface smear for photographic paper and calendered paper; as sizing agent for textile industry.

3. As clarifying agent for glass products.

4. As protective material for radiation; also used for ceramics, enamel, perfumes and pigments.

5. As raw material for the making of other barium salts.

- Q: Method for the determination of barite composition

- Not only is a kind of barite, there are many kinds, some barium sulfate, some not, so the determination of chemical composition of his is not a kind of what you say, only suitable for barium sulfate.

- Q: The naked eye distinguishes calcite, dolomite, K-feldspar, barite, fluorite, quartz

- Fluorite: Fluorite in nature is often bright coloredQuartz is translucent or opaque crystal, generally milk white, hard texture

- Q: The difference between precipitated barium sulfate and white carbon

- Physical appearance: white powder or granular or irregular block. High temperature and no burning, good electrical insulation.

- Q: Ti ore is what?

- Mineral aggregate. In modern technological and economic conditions, metals and other products can be extracted from minerals in an industrial scale. The original refers to solid material mined from metal deposits, has been extended to after the formation of accumulation in the parent rocks of sulfur, fluorite and barite, non metallic minerals.

- Q: How do you value barite? How much is it per ton?. Thank you

- After beneficiation, general industrial products 340-600 yuan / ton, there are thousands of pieces. Fluctuate in line with market conditions。 Time is different, the price is different. Crude ore ranging from 30-200. Excluding freight.

- Q: Types of coal mineralization

- Coal is a solid combustible mineral formed by ancient plants buried in the ground and undergoing complex biochemical and physical and chemical changes. Is a solid combustible organic rock, mainly by the remains of plants after biochemical action, buried, and then changed by geological processes, commonly known as coal. Coal is praised as "black gold" and "food for industry". It is one of the main energy resources used in the human world since eighteenth Century.

- Q: The purpose of processing 2000 barite milling equipment which is good, the highest yield can be achieved?

- As you requested, choose the right one for a number of wet and dry grinding equipment.

- Q: What is the difference between barite and marble

- But also have different colors and the color marble, not subjective think white marble is white, marble is gray, such knowledge is not correct.

- Q: What's the use of barite ore

- Barite deposits in China can be divided into four types, namely, sedimentary deposits, volcanic sedimentary deposits, hydrothermal deposits and residual slope deposits.

- Q: What are the varieties of barite? What is the difference between the specific content?

- Barite is the most common mineral of barium, which is made up of barium sulfate.

1. Manufacturer Overview

| Location | Guizhou, China (Mainland) |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Northern Europe Southern Europe South Asia Domestic Market |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Fangcheng Port In Guangxi,Zhanjiang Port In Guangzhou,Huangpu in Guangzhou |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 1-2 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 4 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | average |

Send your message to us

Superfine Grade Barite Powder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 3000 Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches