Superfine Glass Fiber Insulation Paper For LNG Cylinder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The fire retardation glass fiber Cryogenic & Insulation paper is made of superfine glass fiber with special processing. This is usually used with aluminium foil and used for transport containers which store liquid helium, liquid hydrogen, liquid nitrogen,LNG etc.

The superfine glass fiber Cryogenic & Insulation paper's diameter between 0.1-0.6μm and fiber glass filament (diameter between 3-5 μm). According to a certain proportion, the paper is produced under the wet & vacuum forming process to make the paper have the space lattice structure. All the glass fiber is inorganic material, so it has outstanding flame retardant properties. Specifically engineered for use at big temperature range (approaching -273℃—500℃) and also the paper is really stable in the low temperature condition.

Cryogenic Insulation Paper Features:

The main way of heat conduction is by radiation heat exchange in the low and vacuum condition. In order to reduce the radiation heat exchange to meet the good heat insulation effect, by using aluminum foil for reflecting screen and superfine glass fiber insulation paper for spacer, then the multilayer combination of aluminum foil reflective screen and cryogenic & insulation material can build up the efficient thermal barrier against heat transfer in insulated vacuum storage containers. This material can be freely winding, and help the user to reduce the waste of manpower and material waste.

Cryogenic Insulation Paper Application:

Cryogenic liquid (liquid helium, liquid hydrogen, LNG, liquid oxygen, liquid nitrogen, liquid argon, etc.)

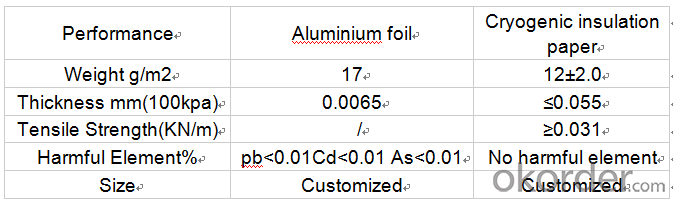

Cryogenic Insulation Paper Specifications

1.light weight

2.good uniformity

3.low thermal conductivity

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Low temperature medical incubator belongs to what high-tech areas

- The advantages are: easy to obtain raw materials, low cost, the use of glass beads in the insulation board, greatly improve the insulation properties; all components with fire characteristics; and the production is simple and easy to produce.

- Q: National medical equipment use personnel ability to assess the qualifications required to confirm what documents required

- Fourth, the candidates registration, qualification and quiz to print ? In 2014, the National Medical Equipment Personnel Service Personnel Qualification Examination Registration was conducted in two phases. The first stage was the online registration name, the second stage was the registration confirmation, ? nuclear. ? Applicants who meet the conditions for registration are listed on September 10, 2014 at 9:00 am to 30:00 on September 30th. China National Health Service (www.21wecan ) ? Prepare the use of personnel business ability evaluation "area, click on" candidates entrance - online registration ", with reference to" candidates online registration operation guide "to complete online registration. ? Completion of online registration of candidates, need to pay close attention to the region health clinic administrative staff on the application of the time and place of registration of the notice, within the specified time will

- Q: Need to do a low-temperature equipment, the temperature inside the box to minus 70 degrees, the insulation layer of 100 mm, what is the insulation layer of material for good insulation? Check with polyurethane PU foam is better, but more expensive. With glass fiber cotton insulation afraid of a long time the insulation layer will have condensate and damage the insulation effect, but look at other foreign similar equipment are used glass fiber cotton insulation, may I ask, in the end can use this material to low temperature insulation? There are detailed technical information that I add another 100 points, thank you!

- Your equipment temperature is zero, you should find cold material! Polyurethane is insulation material! Do not mix the concept!

- Q: Chapter 6 of the management and use of large medical equipment

- The Measures have been implemented since March 1, 2005, and the Interim Measures for the Administration and Application Management of Large Medical Equipment issued by the Ministry of Health Decree No. 43 of 1995 shall be abolished at the same time. December 31, 2004 Large medical equipment management items (first batch) (PET - CT, including positron emission tomography PET) 2, Gamma - ray stereotaxic treatment system (γ - ray emission tomography) (MM50)

- Q: What kind of low temperature drying equipment

- Low temperature drying equipment, there is no industry standard, only the manufacturer standard, and only according to the use of equipment types, low temperature dryer is mainly used for related semiconductor devices, printed circuit boards, electronic components, LCD glass substrate, optical, film and Lenses, quartz vibrators and other electronic components, and other food in low temperature and low humidity storage.

- Q: Will the degree of zero is ultra-low temperature, cold storage is a special equipment?

- Pressure pipe, refers to the use of a certain pressure, for the delivery of gas or liquid tubular equipment, the scope of the provisions of the maximum working pressure greater than or equal to 0.1MPa (gauge pressure), the media for the gas, liquefied gas, steam or flammable, explosive , Toxic, corrosive, the highest operating temperature is higher than or equal to the standard boiling point of the liquid, and the nominal diameter greater than or equal to 50mm pipe. Nominal diameter less than 150mm, and its maximum working pressure of less than 1.6MPa (gauge pressure) of the non-toxic, non-flammable, non-corrosive gas pipeline and equipment, except for the body of the pipeline. Among them, the oil and gas pipeline safety supervision and management should also be in accordance with the "Safety Production Law", "Oil and Natural Gas Pipeline Protection Law" and other laws and regulations.

- Q: Ultra-low temperature refrigerator, medical refrigerator which brand of good

- Refrigerators are actually the same, the general abrasive has a, each other Chuanhuo, find the real manufacturers, cheap, and quality assurance

- Q: How to buy medical shock wave equipment?

- Medical extracorporeal shock wave gravel equipment, generally from the following aspects of the quality of the product:

- Q: Usually high-grade wards are made with a combination of fresco-style equipment and bed locator, as if Wuxi Ningfeng Electronics specializes in this, you can look at their website.

- Seems to be a legal capital, treatment is also quite good. The The The The The Now this kind of foreign-funded enterprises do not seem to recruit through the talent network, do not know what way to understand the recruitment of foreign investment information

- Q: Medical low temperature refrigerator PQ (performance confirmation) has no one done!

- According to the provisions of the medical refrigerator applicable to the national standard, combined with the use of medical features of the refrigerator, designed to confirm the performance of the project, and then completed the test item by item.

Send your message to us

Superfine Glass Fiber Insulation Paper For LNG Cylinder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches