Sunglasses Polycarbonate/Polycarbonate/Bed Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product categories:

PET Hollow Sheet

polycarbonate hollow sheet

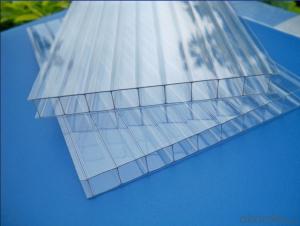

twin-wall polycarbonate hollow sheet

triple-wall polycarbonate hollow sheet

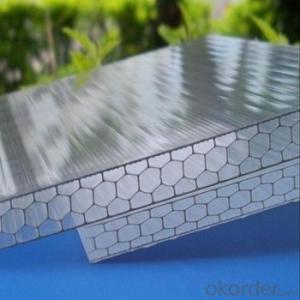

honeycomb polycarbonate hollow sheet

X-profile polycarbonate hollow sheet

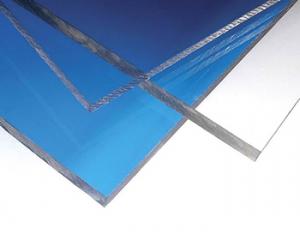

solid sheet one sides UV resistant

Polycarbonate two wall hollow sheet

Thickness: 4mm / 6mm / 8mm / 10mm

Width: 2100mm

Key Features:

High impact strength.

Virtually unbreakable over a wide temperature range (-20°C to 120°C), able to withstand shattering, cracking, crazing or even breaking.

High light transmission-high degree of light transmission while blocking harmful Ultra Violet rays.

Design freedom - lightweight, highly flexible, easy to fabricate on site. Can be easily cold formed and will not crack or splinter when fabricated.

Good fire characteristics - self extinguished material. The sheet does not contribute to flame spread. When subjected to flames from spreading fire, the material only melts away and form holes which releases smoke, gases and heat. It does not emit toxic gases.

Excellent weather ability-I side UV co-extruded, to give longer lifespan of material.

10 years limited warranty - against discoloration, loss of light transmission, and loss of strength due to weathering.

Typical Applications:

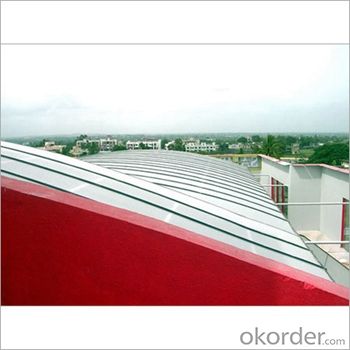

1. Architectural roofing and glazing

2. Skylights and sidelights

3. Displays, signage and decorations

4. Industrial roofing and glazing

5. DIY

6. Covered swimming pools

7. Agricultural greenhouses

FAQ:

1. Q: How can I get a sample?

A: FREE SAMPLE can be sent to you .Freight will be paid.

2. Q: Would you please tell me the company have business relations which countries?

A: Our products are exported to North America, South America, Europe, the middle-south Asia, the Middle East, etc., and have good market in these places.

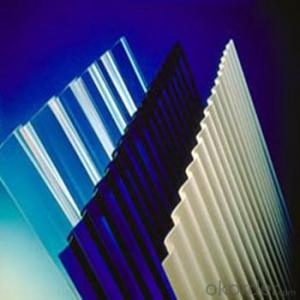

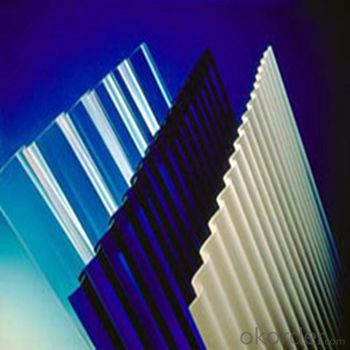

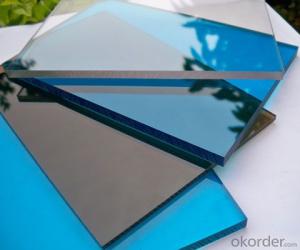

Product Pictures

- Q: What is the difference between sun panels and plexiglass?

- Sun panels are PC polycarbonate materials, sun PC board is usually double-layer structure, the thickness of more than 10mm for the multi-layer and shaped structure. Transparency reached 89%. ??? Cold and heat: -40 ℃ ~ 120 ℃ between the sun plate does not produce deformation. ??? Its own ignition is 580 ℃, self-extinguishing from the fire, burning will not produce toxic gases, will not contribute to the spread of fire.

- Q: PE sun panels and PC sun panels are different

- PC temperature some, much better transparency, PE is not temperature, transparency in general. PE price is about twice as low.

- Q: PC board greenhouses pc board generally use thick? What is the price? What about the current market price? Is the sun board a PC board?

- In addition, most manufacturers will use recycled materials, basically low-cost-based, no guarantee. I suggest you choose, these manufacturers do not ask, boring, save that money is not enough after the repair it So the election board when a principle: want to do the performance of the project, with a good Bayer plate, basically no trouble; want to earn more money or low bid winning project, with the back of the board, anyway, never mind.

- Q: To build a sunshine shed, with Cortron PC patience board or good sun board?

- 1, Cortron sun board Advantages: the German Bayer new materials and co-extruded high concentrations of UV, yellowing effect is good light Light, cover the sun room effect is good 2, Cortron Nai Liban Advantages: good light transmission, up to 88% Good temperature resistance, at minus 40 degrees Celsius to 120 degrees Celsius, there will be no deterioration of quality Sound insulation is good Flame retardant, light weight, safe

- Q: PC sun panels and color steel plate how to bond

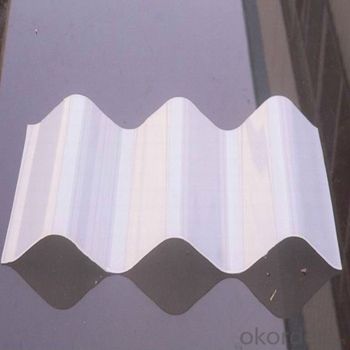

- Sun panels and color plate need to have two corrugated width of the stack, the use of sealant at the same time, with self-tapping screws fixed on the purlins. Such a practice to meet the requirements.

- Q: PC sunshine board, what material, what kind of good

- Sunshine board mainly with light weight, weather, super, flame retardant, sound insulation of the excellent performance, so that we build greenhouse and the canopy and the top of the quality of light, we choose to use the sun can be based on their own practical use Need to choose

- Q: What is the difference between sun panels and lighting panels?

- Construction and waterproofing As the FRP lighting board can be customized according to the needs of exactly the cross-section, so the installation only a small amount of self-tapping screws and silicone tape can be, so easy installation, fast and low cost, good water resistance. As the PC board is based on the main plate, with the corresponding PC and aluminum alloy parts, can play a good connection. And because the PC sunshine board technology, length and thickness can be customized according to customer requirements, is very conducive to the installation and construction of the project.

- Q: What can I do with my own sunshine board?

- Own balcony sun block rain, balcony sun room, interior partitions can be ah

- Q: Lighting board and sunshine board which is good?

- This can not say which is better, can only say which product is suitable for you to use, the general enterprise plant lighting with lighting panels, and some flower room on the temperature requirements of the more stringent must use sun panels and shade net supporting the use.

- Q: What is the difference between the sunboard and the Capron board?

- Sunshine board and the essence of Kaplan is different from the call at home and abroad, like foreign call Capron, domestic call the sun board, Zhejiang Evonik, take you into the PC plate world, distinguished quality, made the world brand.

Send your message to us

Sunglasses Polycarbonate/Polycarbonate/Bed Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords