Strong Packaging Tape with Masking Tape Temperature Resistance in Various Colours

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 60 roll

- Supply Capability:

- 600 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Masking Tape Temperature Resistance Various Colours

1. Structure of Masking Tape Description

The Masking Tape is of crepe paper as the carrier, coating with rubber adhesive. Masking Tape: widely used for paint masking, furniture, shoe material production, automobile painting, light duty packaging etc.

2. Main Features of the Masking Tape

Excellent in adhesion and flame retardant

High Temperature stability

High mechanical strength and good impact resistance

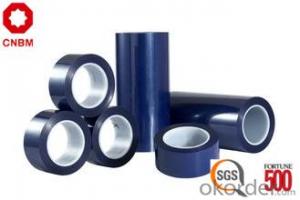

3. Masking Tape Images

4. Masking Tape Specification

Item | Masking Tape |

Adhesive | Rubber |

Thickness (micron) | 160 |

Initial Tack | 10# |

Tensile Strength (N/25mm) | 16 |

Service Temperature (℃) | 80 |

Holding Power (h) | 3 |

Packing | Rolls in Carton |

Certification | SGS and ISO9001 |

5. FAQ

Q1. What is our company?

CNBM International Corporation is a state-owned company. As World Top 500 Company, we have clients from over 120 countries and overseas branches in 5 countries. We specialized in adhesive tape for over 20 years, with SGS and ISO9001 certified and Grade AA for Export.

Q2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

Q3. How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Can packaging tape be used for sealing cloth or fabric items?

- Yes, packaging tape can be used for sealing cloth or fabric items. However, it may not provide the most secure or aesthetically pleasing seal for these items. It is recommended to use specialized fabric tapes or sewing methods for a more effective and durable seal on cloth or fabric items.

- Q: How much weight can packaging tape hold?

- The weight that packaging tape can hold depends on various factors such as the type and quality of the tape, the surface it is applied to, and how it is used. Generally, packaging tapes can typically hold up to 20-30 pounds of weight, but it is always recommended to check the specific guidelines provided by the manufacturer for optimal usage.

- Q: Does packaging tape come in different thicknesses?

- Yes, packaging tape does come in different thicknesses. Packaging tape is available in a variety of thicknesses to accommodate different needs and requirements. Thicker tapes are typically more durable and are suitable for heavy-duty applications where extra strength and resistance are necessary. On the other hand, thinner tapes are often used for lighter packages or general everyday use. The choice of thickness depends on the weight and size of the package being secured, as well as the level of reinforcement desired.

- Q: Can packaging tape be used for sealing plastic storage jars?

- Yes, packaging tape can be used for sealing plastic storage jars. Packaging tape is designed to provide a strong and secure seal, making it suitable for various applications including sealing plastic storage jars. It can effectively keep the contents of the jar protected and prevent any leakage or contamination. However, it is worth noting that there are other options specifically designed for sealing jars, such as jar lids and seals, which may provide a more secure and airtight seal.

- Q: Does packaging tape come in different eco-friendly options?

- Different options are available for eco-friendly packaging tape. Manufacturers have introduced alternatives in response to the growing awareness of the environmental impact caused by traditional packaging materials. These alternatives include packaging tapes made from recycled materials or materials that can biodegrade. Recycled packaging tapes are often made using post-consumer waste, thereby reducing the consumption of new resources. Biodegradable packaging tapes are designed to naturally decompose over time, minimizing their impact on the environment. Furthermore, some packaging tapes utilize water-based adhesives instead of solvent-based ones, thereby further reducing their ecological footprint. These eco-friendly options allow businesses and individuals to select packaging tapes that align with their sustainability goals, while still ensuring secure packaging and shipping.

- Q: Can packaging tape be used for sealing glass windows?

- No, packaging tape is not suitable for sealing glass windows. It is not designed to provide a strong and durable seal on glass surfaces. It is recommended to use appropriate window sealants or weatherstripping for this purpose.

- Q: Can packaging tape be used for sealing plastic flower pots?

- Indeed, packaging tape is capable of effectively sealing plastic flower pots. This versatile adhesive tape is widely utilized for the purpose of sealing boxes and packages. Its robust adhesive properties render it suitable for securely fastening plastic flower pots, thereby preventing any potential leaks or spills. However, it is crucial to ensure that the surface of the plastic flower pot is devoid of dirt or moisture before applying the tape, as the presence of either could compromise its adhesion. Moreover, it is worth mentioning that there exist specialized tapes explicitly designed for sealing or repairing plastic materials, which may offer superior performance and durability when employed on plastic flower pots.

- Q: Can packaging tape be used for sealing sports equipment or gear?

- Yes, packaging tape can be used for sealing sports equipment or gear. It provides a strong and secure seal, helping to protect the equipment during transportation or storage. However, it's important to ensure that the tape is applied properly and that it doesn't damage or hinder the functionality of the gear.

- Q: Can packaging tape be used for sealing wooden crates?

- Yes, packaging tape can be used for sealing wooden crates. It provides a strong and secure bond, ensuring that the crate remains sealed during transportation or storage. Packaging tape is designed to adhere to various surfaces, including wood, making it an effective choice for sealing wooden crates. However, it is important to consider the weight and size of the crate before solely relying on packaging tape. For heavier or larger crates, it may be necessary to reinforce the seal with additional methods such as nails or screws.

- Q: What are the benefits of using transparent packaging tape?

- The benefits of using transparent packaging tape include clear visibility of the contents of the package, easy identification of any tampering or damage, professional appearance, and the tape's durability and strength for securing packages effectively.

Send your message to us

Strong Packaging Tape with Masking Tape Temperature Resistance in Various Colours

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 60 roll

- Supply Capability:

- 600 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords