Steel Wire Rods PVC Coated Steel Wire PVC Coated Rod Iron Wire

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

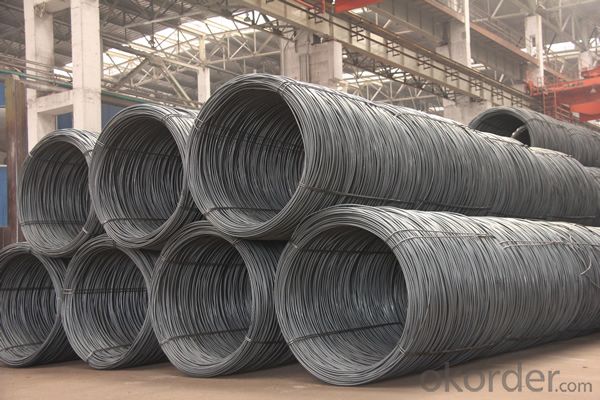

Product Description of Steel Wire Rods PVC Coated Steel Wire PVC Coated Rod Iron Wire:

OKorder is offering Steel Wire Rods PVC Coated Steel Wire PVC Coated Rod Iron Wire at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications of Steel Wire Rods PVC Coated Steel Wire PVC Coated Rod Iron Wire:

Steel Wire Rods PVC Coated Steel Wire PVC Coated Rod Iron Wire are ideal for structural applications and are widely used in construction and manufacturing. Carbon steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts , nail, etc.) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

Product Advantages of Steel Wire Rods PVC Coated Steel Wire PVC Coated Rod Iron Wire:

OKorder's Steel Wire Rods PVC Coated Steel Wire PVC Coated Rod Iron Wire are durable, strong, and wide variety of sizes. They are newly produced by good quality steel billets.

Main Product Features of Steel Wire Rods PVC Coated Steel Wire PVC Coated Rod Iron Wire:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications of Steel Wire Rods PVC Coated Steel Wire PVC Coated Rod Iron Wire:

Steel Grade: SAE1006-1018B

Standard: ASTM, GB

Diameter: 5.5mm, 6.5mm, 7mm,8mm,9mm,10mm,12mm,14mm

Type: in coil, coil weight around 2MT

Alloy or Not: Alloy

Technique: Hot Rolled

Place of Origin: China Mainland

Surface: round, no twisted, light and smooth

FAQ:

Q1: Why buy Hot Rolled Low Carbon Steel Wire Rods for Nails, Steel Wire Mesh from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Packaging & Shipping

plastic film per bundle ,strapped with metal wire and then put into carton box .

- Q: How is steel wire rod used in the manufacturing of wire forms for roller coasters?

- Steel wire rod is a crucial component in the manufacturing of wire forms for roller coasters. It serves as the raw material from which various wire forms are created, such as track supports, safety restraints, and other structural elements. The high tensile strength and durability of steel wire rod make it an ideal choice for roller coaster construction. Roller coasters experience immense forces and stresses during operation, including bending, twisting, and sudden changes in velocity. Steel wire rod offers exceptional strength and flexibility, enabling it to withstand these forces and maintain its structural integrity. To manufacture wire forms for roller coasters, the steel wire rod is first carefully selected for its specific mechanical properties, such as tensile strength and ductility. It is then processed through a series of stages, including drawing, annealing, and galvanizing. Drawing involves pulling the wire rod through a series of dies to reduce its diameter and increase its length, resulting in a wire with the desired dimensions. Annealing, a heat treatment process, is performed to enhance the wire's flexibility and reduce its brittleness. This is crucial for ensuring the wire forms can withstand the constant vibrations and movements experienced during roller coaster operation. Finally, the wire forms are galvanized to provide corrosion resistance. This involves coating the wire with a layer of zinc, which protects it from environmental elements, such as moisture and oxidation, thereby extending its lifespan. Once the steel wire rod has been processed and transformed into wire forms, it is used in various applications throughout the roller coaster. For example, it may be used to create the track supports that hold the coaster's rails in place, ensuring stability and safety. Additionally, it can be used to manufacture safety restraints, such as lap bars and shoulder harnesses, which are vital for securing passengers during the thrilling ride. In summary, steel wire rod plays a crucial role in the manufacturing of wire forms for roller coasters. Its exceptional strength, flexibility, and durability make it an ideal material for constructing various structural elements and safety components. By undergoing careful processing and treatment, steel wire rod ensures the safety and exhilaration of roller coaster riders around the world.

- Q: How is steel wire rod used in the manufacturing of wire rope turnbuckles?

- Steel wire rod is used in the manufacturing of wire rope turnbuckles as it serves as the primary material for the production of wire ropes. The wire rod is first drawn into wires of specific diameter and then twisted together to form strands, which are further twisted together to create the wire rope. This wire rope is then utilized to construct the core component of a turnbuckle, providing the necessary strength, durability, and tensioning capabilities required for various applications.

- Q: What are the different wire drawing lubricants used for steel wire rod?

- There are several different wire drawing lubricants used for steel wire rod, including soap-based lubricants, oil-based lubricants, and synthetic lubricants. Soap-based lubricants are commonly used for mild steel wire rod, as they provide good lubrication and cooling properties. Oil-based lubricants are often used for high carbon and alloy steel wire rod, as they offer better lubrication and reduce friction during the drawing process. Synthetic lubricants, such as water-based polymer lubricants, are also used to improve surface finish and reduce wear on the wire rod during drawing.

- Q: How is steel wire rod used in the manufacturing of wire forms for aerospace applications?

- To manufacture wire forms for aerospace applications, steel wire rod is essential. It serves as the starting material for wire drawing, which involves a series of processes to produce wire forms with specific dimensions and characteristics. The first step is to carefully select high-quality steel wire rod that meets the strict standards of the aerospace industry. This ensures that the wire forms will possess the necessary strength, durability, and corrosion resistance required for aerospace applications. Once the suitable steel wire rod is obtained, it is passed through a wire drawing machine with a series of dies. This process involves pulling the wire rod through progressively smaller dies, resulting in a reduction in diameter and an increase in length. Wire drawing not only shapes the wire but also refines its microstructure, leading to improved mechanical properties. Following wire drawing, the steel wire undergoes further processing based on the specific requirements of the wire forms. It may undergo additional treatments such as heat treatment, surface coating, or plating to enhance its performance and meet the rigorous aerospace industry standards. The wire forms produced from steel wire rod find extensive use in the aerospace sector. They are employed in the manufacturing of various aircraft components, including springs, fasteners, connectors, wire harnesses, and control cables. These wire forms play a vital role in ensuring the structural integrity, functionality, and safety of different aerospace systems. The utilization of steel wire rod in the production of wire forms for aerospace applications offers numerous advantages. Steel is renowned for its high strength-to-weight ratio, excellent fatigue resistance, and good electrical conductivity. These properties make steel wire forms ideal for withstanding the demanding conditions experienced in the aerospace industry. In conclusion, steel wire rod is an indispensable raw material in the manufacturing of wire forms for aerospace applications. Through processes like wire drawing and additional treatments, it is transformed into wire forms with the necessary properties to meet the stringent requirements of the aerospace industry. These wire forms significantly contribute to the structural integrity and functionality of various aerospace systems.

- Q: How does the magnetic properties of steel wire rod vary with different heat treatment processes?

- The magnetic properties of steel wire rod can vary significantly with different heat treatment processes. Heat treatment processes such as annealing, quenching, and tempering can influence the microstructure and crystallographic orientation of the steel, which in turn affects its magnetic properties. For example, annealing can result in the formation of a soft magnetic structure with improved magnetic permeability, while quenching and tempering can produce a harder magnetic structure with higher coercivity. Overall, the specific heat treatment process employed can determine the magnetic properties of steel wire rod, making it possible to tailor its magnetic characteristics for specific applications.

- Q: How is steel wire rod used in the production of wire shelves and racks?

- Wire shelves and racks rely on steel wire rod as a vital component for their production. This material serves as the primary building block for constructing these storage solutions. To begin, the steel wire rod undergoes processing and drawing to attain the desired shape and size for the shelves and racks. This involves passing the rod through a series of dies and rollers, transforming it into a thinner and more pliable wire form. Once drawn, the wire is then bent, cut, and welded to create the essential elements of the shelves and racks. The wire rods are shaped into grids, frames, and supports, forming the fundamental structure of these storage units. The wire rods also play a crucial role in crafting the mesh or grid patterns that make up the shelving surfaces. These grids allow for the safe storage of various items, preventing them from falling through gaps. Moreover, the steel wire rod provides the necessary strength and durability to the shelves and racks. Its high tensile strength ensures that the shelves can withstand heavy loads without bending or breaking, making them suitable for industrial use where robust storage is required. Furthermore, the steel wire rod is often coated or galvanized to enhance its resistance to corrosion. This protective coating safeguards the shelves and racks from rust and other forms of deterioration, extending their lifespan and preserving their appearance. In conclusion, the utilization of steel wire rod in the production of wire shelves and racks is indispensable. It offers the essential strength, durability, and functionality required for effective storage solutions in a variety of settings, including homes, offices, warehouses, and retail spaces.

- Q: What are the common production processes for uranium-coated steel wire rod?

- The common production processes for uranium-coated steel wire rod typically involve several steps. First, the steel wire rod is cleaned and prepared to remove any impurities. Then, a layer of uranium is deposited onto the surface of the wire rod through a process called electroplating or electro-deposition. This involves immersing the wire rod in a solution containing uranium ions, and using an electric current to attract and deposit the uranium onto the surface of the rod. Once the desired thickness of uranium coating is achieved, the wire rod is inspected for quality and undergoes further treatments, such as drying and curing, to ensure the adhesion and durability of the coating. Finally, the uranium-coated wire rod is ready for use in various applications, such as nuclear fuel production or other specialized industries.

- Q: What are the different surface finishes available for steel wire rods?

- There are several surface finishes available for steel wire rods, including hot-dip galvanized, electro-galvanized, phosphatized, and uncoated. Each finish offers unique properties and benefits depending on the intended application and environmental conditions.

- Q: How does the brittleness of steel wire rod vary with different wire drawing processes?

- The brittleness of steel wire rod can vary with different wire drawing processes. Generally, the more intense the wire drawing process, the higher the brittleness of the steel wire rod. This is because the wire drawing process involves reducing the diameter of the wire rod, which can result in an increase in internal stress and dislocations within the material. These defects can make the steel wire rod more prone to fracture and reduce its overall toughness. However, with proper heat treatment and control of the wire drawing parameters, it is possible to minimize the brittleness and enhance the mechanical properties of the steel wire rod.

- Q: What are the key success factors for companies in the steel wire rod industry?

- The key success factors for companies in the steel wire rod industry include efficient production processes, high-quality products, strong supply chain management, competitive pricing, effective marketing and sales strategies, and the ability to adapt to changing market conditions. Additionally, maintaining strong relationships with customers and suppliers, investing in research and development to innovate and improve products, and ensuring compliance with industry regulations are also crucial for success in this industry.

Send your message to us

Steel Wire Rods PVC Coated Steel Wire PVC Coated Rod Iron Wire

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords