Steel Pipe Fittings Butt-Welding Reducing Outlet Tees High Pressure

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Pipe Fittings Butt-Welding Reducing Outlet Tees

Features standards and products of our butt welding fittings:

Features of Butt-Welding Reducing Outlet Tees:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of Butt-Welding Reducing Outlet Tees:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process of Butt-Welding Reducing Outlet Tees:

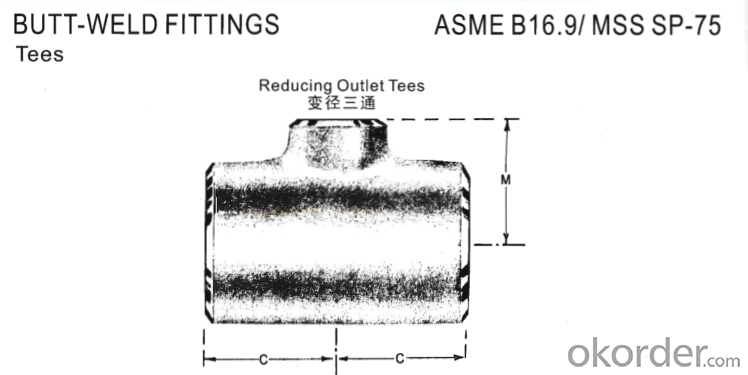

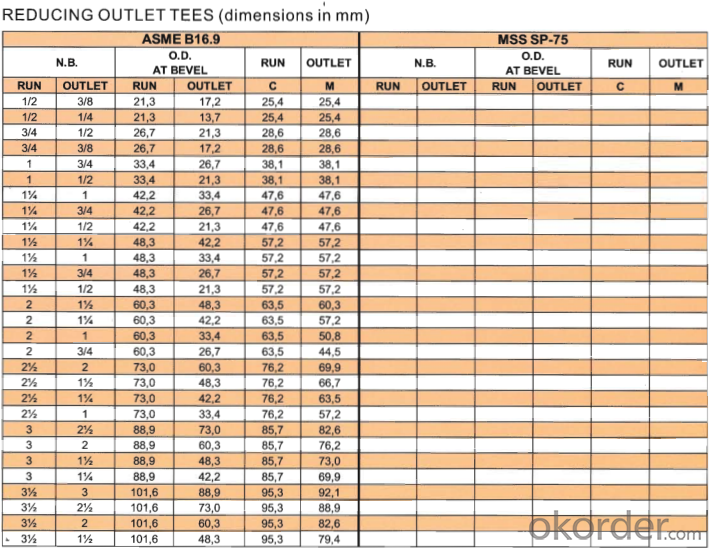

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Reducing Outlet Tees:

Packing of Butt-Welding Reducing Outlet Tees:

FAQ of Butt-Welding Reducing Outlet Tees:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q: I'm in a chemistry lab and trying not to have a noticeable pair of goggles on. I'm looking for a pair (to buy online etc.) that is very subtle, maybe even has clear parts that rest on your ears etc.

- Suppose you have a membrane stretched as a plane sheet over a long area. if you leave a small ball on it it will remain as it is . But if you now put 1 kg at some point on the membrane and then put a small ball anywhere, you will find that the ball will run towards the heavyweight. Now you may interpret it as if the weight is attracting it or you may say that the space around the heavy weight is curved so that everything else around it tries to move towards it. Classical Newtonian gravitation makes the first kind of postulate that masses attract each other. Whereas Einstein makes the assumption that the space itself bends around massive objects. Now how do u decide the bending of space. We know that light travels in straight line. So if light travels in straight line in certain region the space is not curved but if it bends then the space is curved. This hs been verified by experiments done during Solar eclipse.

- Q: i was wondering cuz we were messing around with one we found and my boyfriend said to make sure i dont breathe it in. i didnt try to and did and it wasn't much but i was curious if that's why he said not to(he hates people getting high) i wasnt trying to by the way. i'm just curious.

- The interconnect signals aren't standard across different manufacturers (and sometimes not even between different models from the same manufacturer). I'd be inclined to just bite the bullet and replace them all with the same model at the same time (then you know they'll work together). The wired interconnect models may never be standardized as it appears most manufacturers are moving towards the wireless interconnects (which probably aren't standardized either). :/

- Q: I suck at this stuff. I have an F and grades close really soon.1. Potential energy is the energy of?2. Kinetic energy depends on?3. Gravitational potential energy depends on?4. 5 renewable resources and 5 nonrenewable resources.5. What kind of energy is stored in a stretched rubber band?6.At what point does a roller coaster have the greatest potential energy?Help if you can please. I'll answer any question you want if I can!!Thank you. (:

- There could be a number of things wrong here.The Valve it self could be leaking.One of the PVC pipe fittings could be leaking.Or there is a broken pipe. To shut the water off at the Valve.This can only be done if the Valve has a flow control.If it has a flow control handle,you will see a handle on the top of the Valve. Or you could just turn the water off to the entire Irrigation System.If you are on city water there is what is called a Back Flow Preventer.This is code in most all city water systems.They generally are about 12 inches above the ground,and have one to two Gate or Ball Valves on them.

- Q: home security alarm was activated by a remote - not ours. has it ever been reported that a car alarm activated a home security alarm?

- I would say that the most dangerous aspect of not measuring groove depth would be the reduction in wall thickness. If the groove depth is not checked, it is possible that the groove could be too deep in the pipe, causing a weak point where the pipe could rupture. Even if it doesn't happen during the pressure test, the corrosion allowance of the pipe is reduced to the point that a small amount of corrosion could result in failure. If the grooves are too deep the Victaulic fittings will also not limit the angle of adjoining pipes as designed. This could potentially lead to leaks. Although I don't think this is likely given the hydraulically loaded gasket design.

- Q: What are the differences between hydraulic couplings and fittings and elbows?

- The elbow is the pipe that changes the direction of the pipe. According to the angle, there are 45 degrees and 90 degrees, 180 degrees, three most commonly used, in addition, according to the project needs, including 60 degrees and other non normal angle elbow. Elbow materials are cast iron, stainless steel, alloy steel, malleable cast iron, carbon steel, nonferrous metals and plastics. The way to connect with the pipe is: direct welding (the most commonly used way), flange connection, hot melt connection, electric melting connection, threaded connection and socket connection. According to the production process can be divided into: welding elbow, stamping elbow, push elbow, casting elbow, butt welding elbow. Other name: 90 degree elbow, right angle bend, love bend and so on.

- Q: How do I distinguish the rigid clamp joint and the flexible clamp joint from the outward appearance?

- The connecting bolts are different, and the flex is 2 larger than the rigidity (with 159 clamps as an example)The two semicircle butt joint is different, the flexible clamp is butt joint, and the rigid clamp is embedded butt joint

- Q: I live in a studenthouse. In this house I have a small room and I dry my clothes just outside the room. But my landlord is not happy with me and others who live in this house. He says that he will allow things to be put in the hall anymore. This is because of fire safety. But I don?t like drying clothes inside the room I sleep, cook, and live in. Before I?ve noticed that this had led to health problems. What can I do? My landlord will throw all my clothes away if he finds them?

- THIS IS EASY. TAKE A PROPANE TORCH AND LIGHTLY HEAT THE INSIDE OF THE POLY PIPE.(5 SECONDS)GET A FIRM GRIP ON THE POLY THE INSERT ADAPTER WILL SLIDE RIGHT ON. WE DO THIS EVERY DAY.

- Q: there is a lot of reckless driving in my neighborhood, we have even had a speed trap put up but nothing stops it. I see 10yr olds driving golf carts to the pool all the time. accidents have happened, when will this madness stop. this is some of my ideas on the driving subject in my neighborhood, any problems in yours? give exampls to elaborate on your point please

- Yes. I did that just the other day. I turned on the water, and the hose fell off. It was squirting everywhere!

- Q: hi i have a problem with my car alarm, whenever i put it on (as i like to overnight) it always sets its self off at the same time approx 5:30 in the morning! and ideas?i have a nissan micra K11

- Its most likely either be the brass fitting soldered to the copper pipe where the nipple is screwed into or the nipple needs to be tightened. My bet is that the brass fitting is cracked, they tend to do that often. The copper pipes and fittings flex a lot more before they break, the brass will just crack. Either way its probably easier to go in from the wall you are talking about. If you have a tub surround, it will be a royal pain, and will be alot harder if you have a tile surround. Use a utility knife and cut out a square gradually. You will need to screw thin plywood behind the sheetrock that is there so you have something to secure the piece you cut out onto when you go to patch it up. When it is cut out just run the water and check for the leak, if it is hard to find the exact location, use soapy water or leak detector on all the possible locations and look for the bubbles.

- Q: And it's not coming from the machine itself, it's adding this noise, it's coming through the speakers. ( speakers are fine with normal TV) but every time I try to record something from the VCR to the DVD, the wine goes with it and gets louder. I've tried multiple tapes, in multiple machines so I'm convinced it's not my tapes. I've also cleaned it with the VCR head cleaner. it still won't quit whining. What should I do? this is only a year old so9 replacing it is not what I want to hear.

- This Site Might Help You. RE: looking for Pipe Fitters Manual Tube-Turn Welding fittings and Flanges? I'm looking for a Pipe Fitters Manual by Tube Turn for Welding Fittings and GFlanges it has alot of fomulas and conversions in it. It's made by Tube Turns Division of Chemetron Corp. Louisville KY 40201

Send your message to us

Steel Pipe Fittings Butt-Welding Reducing Outlet Tees High Pressure

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords