Steel bar truss floor deck

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

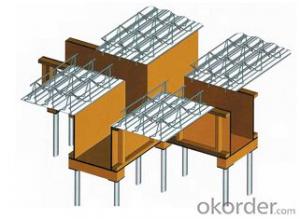

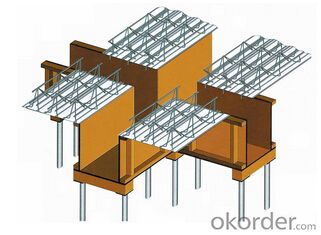

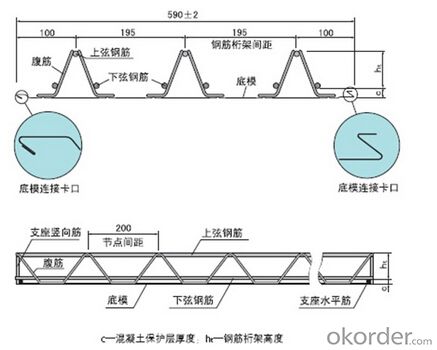

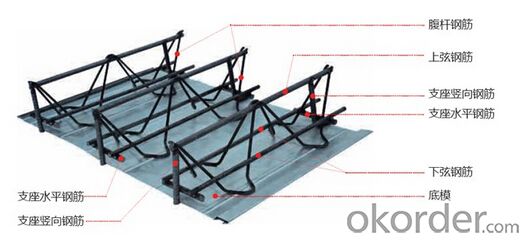

DUOWEI steel bar truss floor deck is the integrated fabricated formwork for which steel bar is to be processed into steel bar truss and then the steel bar truss is to be welded with galvanized profiled sheet. In the construction stage, the steel bar truss floor deck can bear the construction load; moreover, concrete can be poured after steel bars are directly laid on the beam for simple steel bar works. As form functions can be completely replaced, form erection and removal works can be reduced, so floor slab construction efficiency can be greatly improved.

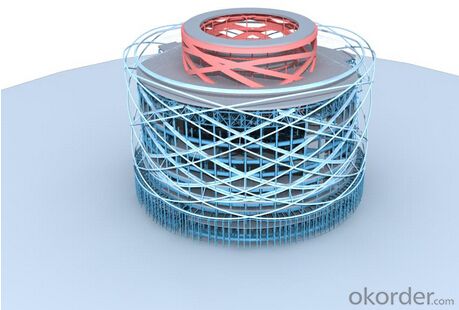

DUOWEI steel bar truss floor deck has features such as economy, convenience, safety and reliability, etc and it has been widely used by structure and building fields such as multilayer workshops, multilayer, high-rise and ultra-high steel structure buildings and various irregular floors, concrete structures and high speed railway, etc.

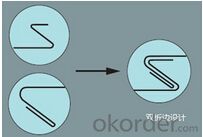

1. Unique double folding design

Effectively increase board edge strength; hard to bend or deform during transportation and construction;

Ensure edge straightness of product, fastening of bottom form gets easier;

Improve compactness of bottom form lapping, effectively prevent leakage;

Improve construction quality and protect customer’s interests.

2. Improved form spot welding technology

Original form spot welding equipments are improved to make welding current of many welding heads more balanced and stable, so the floor deck to be made will be free from cold joint or weld penetration phenomenon.

Four advantages

Economic

The load-bearing mode of the truss is reasonable, the consumed materials economic, and the advantage of integrated costs obvious.

It can be designed into two-way slab, with adjustable truss height and diameter of reinforcement, intended to apply to the floor slab of larger span.

Convenient

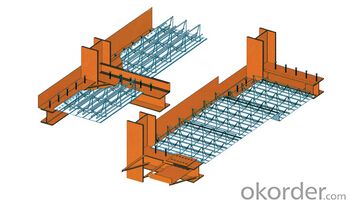

The field steel binding quantity is reduced by 60% - 70%, and the construction period is further shortened.

The load-bearing mode of the truss is reasonable, which can provide greater stiffness to floor beating slab, greatly reducing or even sparing the use of temporary bracing.

Safe

The mechanical property is basically the same as the traditional floor slab, with good crack resistance.

The fire-resistant performance is equal to the traditional floor slab, superior to the profiled steel plate composite slab.

The bottom die is not loaded in the use phase, eliminating the consideration to fire and corrosion problems.

Reliable

The reinforcements are arranged uniformly, and the spacing between two layers of reinforcements and the thickness of concrete cover are reliably guaranteed.

The two-way stiffnesses of the floor slabs are similar, conducive to the seismic stud welding, so the quality is easier to ensure.

- Q: Malacca plate true and false how to identify

- Malacca plate true and false identification methods are as follows: 1, there is no taste in the processing process: Malacca ecological board if there is no pungent taste, is false ecological board. Because the material is Malacca, and Malacca would have a taste, but the taste is the tree itself comes and is described as harmless. 2, if the substrate is too hard to note: the substrate is too fake eco-board, Malacca plate is soft, easy to deformation. 3, Edge of the problem, Malacca ecological board if there are unpleasant, there is a flattening phenomenon, the ecological board itself is a problem. Although Malacca is softer, good Malacca ecological board will not appear edge flattening phenomenon. Malacca core board, the use of Malacca wood processing and production of man-made sheet, are semi-finished products. While the Malacca sheet is the use of this material core plate made of finished sheet. High quality Malacca wood, with colorful, strong texture, texture clear, colorful and other advantages, because of its wood properties, Malacca plate color expression than any kind of wood grain. Malacca ecological sheet, but also take into account the wear resistance, scratch resistance, corrosion resistance, anti-aging, excellent flame retardant properties, even after the damp air will not be deformed, the quality is always new.

- Q: How to go to the market to pick a good plate?

- 1, the choice of woodworking board is particularly important. It is recommended to buy Glulam, because the laminate is solid wood, no outer skin, not easy to make fake. If you use blockboard, choose the big manufacturers, such as Langfang Jinqiu, Zhejiang Moganshan, the board was above the manufacturer's security check phone. And each board has its only serial number, like a person's identity card, can not do the fake! 2. Australian pine board is now mostly domestic, but little impact on the quality of decoration, as long as the quasi-price, it will not be too fooled. 3. The choice of the first panel depends on the color texture of the veneer, the natural veneer has a slight color difference, the artificial veneer texture is very consistent, but looks fake; followed by the bottom plate material, Liu An core floor is now very little, the panel snapped inside the folder wire. Poplar core prone to primer dialysis, a long time the surface of the paint pollution. Zamu core of the basic quality can be, and economic and durable. In fact, it is easy to say, but the layman is difficult to see inside the essence, it is best to ask a professional friend to help choose.

- Q: What are the differences between FR5 sheet and FR4 sheet?

- FR-5 has better advantages than FR-4: 1, TG, TD higher; 2, better heat resistance, about twice the normal FR-4; 3, Z-CTE smaller, suitable for high Laminates; 4, T288 better.

- Q: What kind of plate is the decoration with the density board?

- In daily life, people commonly referred to as the MDF, but also can be called fiber board, it is made of wood fiber, or other plant fiber as raw materials, plus urea-formaldehyde resin, or other appropriate adhesive made of man-made sheet. Since it is called MDF, then it must have a certain density. Therefore, according to their density, we can divide the MDF into three categories: low density board, medium density board and high density board. In view of the MDF texture is soft, and the impact resistance is relatively strong, but also relatively easy to re-processing, so abroad, MDF is a very good material making furniture. However, because the domestic demand for high-density board is much lower than the international standard, therefore, the quality of China's MDF should also be further improved.

- Q: 2.2 meters high 3.5 meters deep 30, no hardware, probably the following, the budget probably how much!

- I was selling the brand name of the overall kitchen cabinet, according to the figure: If the overall 450 yuan / square: 450X7.7 = 3465 yuan, If the expansion of the calculation: 18 PCT side board 2.2X0.3X8 = 5.28 18% baffle 2.2X0.3X2 = 1.32 18 layers 3.5x0.3X6 = 6.3 5 PCT backplane 2.2X3.5X1 = 7.7 Material Amount: 18 PCT = 220 yuan / square X12.9 = 2838 yuan 5% = 135 yuan / square X7.7 = 1039.5 yuan A total of 3877.5 yuan Count all the good material,

- Q: Europe to send cabinet cabinet board board what advantage

- Europe to send cabinet cabinet board accounted for 80% of the entire cabinet plate, its excellent real decision of the cabinet durability and environmental protection. Europe to send cabinets cabinet body board formaldehyde emission is very low, all in line with the European E1-class environmental standards. Surface smooth, high density, good bending performance, easy to deformation. The cohesion of the plate is good and the nail is strong. Base material structure is uniform, dense, open material will not appear loose collapse, plate quality and stability. Europe to send cabinet cabinet board board all the German hammer edge machine edge, PVC edge of the German imports of the world's top Swiss brand, to 1.5MM, and the use of the world's advanced plastic coating technology, Finished, and in the process of sealing at the same time trimming, polishing treatment, so that the edge smooth, neat, beautiful, good sealing, waterproof moisture, to ensure that Europe to send cabinets cabinet life.

- Q: Ask: PB, MDF plate is generally what is the quality of good or bad?

- MDF Particleboard (PB) ?? Now many of the furniture industry is MDF board, because he has a lot of similar nature with the solid wood, the advantage is that it is much cheaper than solid wood. ?? The PB board is generally less than the MDF plate because it is rough and the edges are not flat. But the price is lower than the MDF, the strength can also be, that is, the amount of methanol will be more. ??? If you do the cabinet is topical, just used to put the tool (iron or other), I think the PB board can be considered. But if your cabinet is used indoors, it is recommended to go through the painting. ??? In addition, if your cabinet is used to put water-related, it is recommended to use MDF board, because it is more water-resistant than the PB board, after the water is not easy to deformation. I am glad to answer the question of the landlord if any mistakes please forgive me

- Q: What are the types of plates for office furniture?

- Blockboard Blockboard, commonly known as big core board. Daxing board is made of two pieces of veneer stamping together. Big core board price is cheaper than the core board, the vertical (to the core material to distinguish) bending strength is poor, but the lateral bending strength is higher.

- Q: Now home furnishings are what plate?

- Solid wood board As the name suggests, solid wood is made of complete wood made of wood. These plates are rugged, natural lines, is the best choice in the decoration. However, due to the high cost of such plates, and the construction process requires high, but not much use in the decoration. Solid wood panels are generally classified according to the physical name of the plate, there is no uniform standard specifications.

Send your message to us

Steel bar truss floor deck

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords