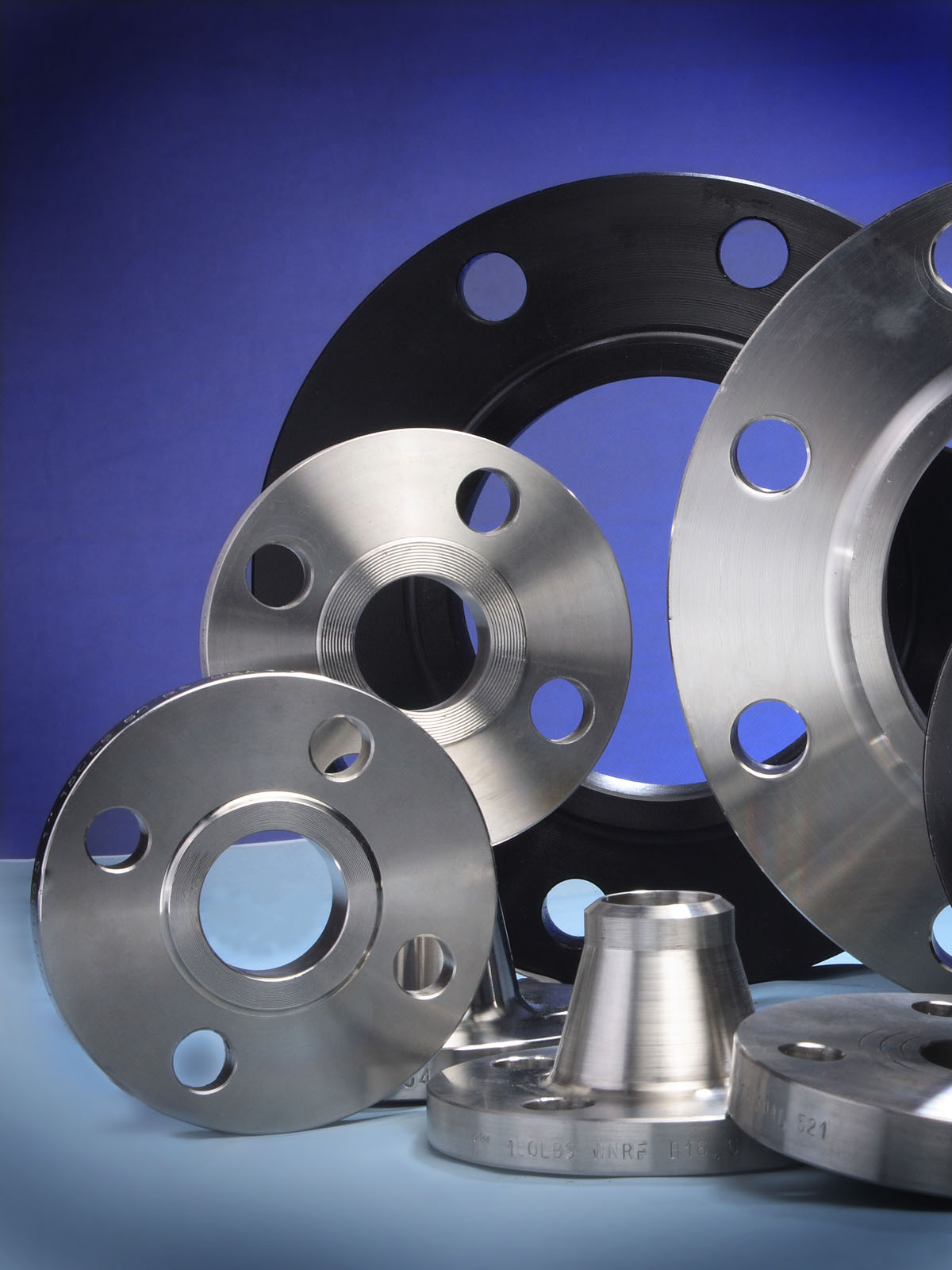

Stainless Steel Fittings TP304

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 10000 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Fittings

Specifications Features:

1) Carbon steel fitting and stainless steel fitting

2) Standard: ASME, ANSI, API, JIS

1. BUTT WELDED FITTING:

2. Production acc. to the standard of GB /ASTM / ASME / DIN / JIS

ASTM B 16.9 /16.11 B 16.28 JIS B 2311/2220 DIN2617/2616/2615/2391

3. Types: Elbows, seamless and welded, LR & SR ,Bend -Equal and reducing Tees,

seamless and welded - Concentric and eccentric Reducers,seamless and welded -Caps

4. Wall thickness: From Sch5 up to Sch160/STD/XS/XXS

5. Material Grades: A403,WP304, WP304L, Wp316, WP316L, A234WPB

6. Dimensions: Seamless: from 1/2' up to 24'

7. size: From 1/2" up to 72"

Outer packing:Seaworthy plywood case

|

Grade |

TP304,TP304L,TP321,TP316L,TP310S etc. |

|

connection |

welding |

|

techniques |

forged |

|

Surface finishing |

180/240/320/400 grit |

- Q: Are stainless steel flats suitable for magnetic applications?

- Yes, stainless steel flats are suitable for magnetic applications. While stainless steel is not inherently magnetic, certain grades of stainless steel can be magnetized through a process known as cold working or by adding specific alloying elements such as nickel or manganese. These magnetizable stainless steels are commonly referred to as austenitic stainless steels. They can exhibit a magnetic response when subjected to a magnetic field, making them suitable for various magnetic applications. However, it is important to note that not all stainless steel flats are magnetic, as there are different grades and types of stainless steel available with varying magnetic properties. Therefore, it is crucial to select the appropriate grade of stainless steel flat that meets the specific magnetic requirements of the application.

- Q: What are the common width tolerance limits for stainless steel flats?

- The common width tolerance limits for stainless steel flats typically range from +/- 0.005 to +/- 0.030 inches, depending on the specific grade and thickness of the material.

- Q: Can stainless steel flats be used in the production of pressure vessels?

- Indeed, the utilization of stainless steel flats is feasible in the manufacturing of pressure vessels. Stainless steel, renowned for its exceptional resistance to corrosion and robustness, is widely favored when selecting materials for pressure vessels. Its ability to endure high pressure and extreme temperatures renders it suitable for numerous industries, notably oil and gas, chemical, and pharmaceutical. In the construction of pressure vessel components such as shells, heads, and flanges, stainless steel flats are frequently employed as raw materials. These flats provide benefits such as longevity, durability, and ease of fabrication and welding. Furthermore, stainless steel can be effortlessly cleaned and maintained, ensuring the ongoing integrity of the pressure vessel.

- Q: Can stainless steel flats be used in construction industry?

- Yes, stainless steel flats can be used in the construction industry. Stainless steel is a durable and corrosion-resistant material that is commonly used in construction for various applications such as structural support, cladding, roofing, and decorative elements. Its strength, aesthetic appeal, and resistance to rust make it a popular choice in the construction industry.

- Q: Can stainless steel flats be used in the water and wastewater industry?

- Yes, stainless steel flats can be used in the water and wastewater industry. Stainless steel is known for its excellent corrosion resistance, making it an ideal material for applications involving exposure to water and wastewater. The high chromium content in stainless steel forms a protective oxide layer on the surface, preventing the material from rusting or corroding. This makes stainless steel flats suitable for use in various water and wastewater industry applications such as pipes, tanks, pumps, valves, and fittings. Additionally, stainless steel's strength and durability allow it to withstand the harsh conditions often found in the water and wastewater industry, including high temperatures, pressure, and chemical exposure. Furthermore, stainless steel is hygienic and easy to clean, making it a preferred choice for industries where cleanliness and sanitation are crucial. Overall, stainless steel flats are a reliable and long-lasting option for use in the water and wastewater industry.

- Q: How do stainless steel flats perform in abrasive environments?

- Stainless steel flats excel in abrasive environments, offering high reliability and exceptional performance. With its unique composition, including a significant amount of chromium, stainless steel possesses excellent resistance to abrasion, corrosion, and wear. Therefore, stainless steel flats are suitable for a wide range of abrasive environments, such as mining, construction, manufacturing, and marine applications. The presence of chromium in stainless steel generates a thin, protective oxide layer on the surface, commonly known as the passive film. This passive film acts as a barrier, effectively shielding the material from abrasive particles, preventing any potential damages. Moreover, stainless steel flats can be further enhanced by incorporating various alloying elements like nickel and molybdenum, significantly boosting their resistance to corrosion and wear. Stainless steel flats also exhibit remarkable durability and longevity, making them a cost-effective option for abrasive environments. They can endure high impact and maintain their structural integrity even under harsh conditions. Additionally, stainless steel flats have exceptional heat resistance, enabling them to withstand extreme temperatures without warping or compromising their mechanical properties. In terms of maintenance, stainless steel flats are relatively effortless to clean and require minimal upkeep. A simple wipe or a mild soap and water wash are sufficient to eliminate any abrasive particles or contaminants. This practicality renders stainless steel flats an ideal choice for environments where cleanliness and hygiene are of utmost importance. In conclusion, stainless steel flats are an ideal solution for abrasive environments due to their outstanding resistance to abrasion, corrosion, and wear. Their durability, strength, and low maintenance requirements make them the perfect choice for applications that involve constant friction, impact, or exposure to abrasive substances.

- Q: What are the dimensions available for stainless steel flats?

- The dimensions available for stainless steel flats can vary depending on the manufacturer and supplier. However, common dimensions for stainless steel flats typically range from 1/8 inch to 1 inch in thickness and 1/2 inch to 6 inches in width.

- Q: Can stainless steel flats be used in the renewable energy industry?

- Yes, stainless steel flats can be used in the renewable energy industry. Stainless steel is known for its excellent corrosion resistance, durability, and strength, making it a suitable material for various renewable energy applications. One common use of stainless steel flats is in the construction of wind turbines. These flats are used to build the tower, nacelle, and other structural components of the turbine. Stainless steel's corrosion resistance ensures that the turbine can withstand harsh environmental conditions, such as exposure to saltwater or high humidity, without rusting or deteriorating over time. Stainless steel flats are also used in the production of solar panels. They are often used to make the frames and mounting structures for the panels, providing stability and support. Stainless steel's strength and resistance to extreme temperatures make it an ideal material for these applications. Additionally, stainless steel flats are used in the manufacturing of various renewable energy equipment, such as heat exchangers, solar water heaters, and biomass boilers. These flats are chosen for their ability to handle high temperatures, pressure, and corrosive environments. Overall, stainless steel flats are a versatile and reliable material for the renewable energy industry. Their properties make them suitable for a range of applications, ensuring the longevity and efficiency of renewable energy systems.

- Q: What are the common types of stainless steel flats available in the market?

- In the market, there is a variety of stainless steel flats readily accessible, each belonging to different categories. Some of these include: 1. Austenitic Stainless Steel: Renowned for its exceptional corrosion resistance, low magnetic properties, and high ductility, this type of stainless steel finds applications in numerous fields such as kitchen utensils, food processing equipment, and architectural structures. 2. Ferritic Stainless Steel: Characterized by its high chromium content, which imparts good resistance to corrosion and oxidation, ferritic stainless steel is commonly utilized in automotive exhaust systems, heat exchangers, and appliances. 3. Martensitic Stainless Steel: Known for its remarkable strength and hardness, martensitic stainless steel is commonly employed in applications requiring excellent wear resistance, such as cutlery, surgical instruments, and industrial equipment. 4. Duplex Stainless Steel: Combining the qualities of austenitic and ferritic stainless steels, duplex stainless steel strikes a balance between the two. It offers good corrosion resistance and high strength, making it suitable for applications in the chemical, oil and gas, and marine industries. 5. Precipitation Hardening Stainless Steel: This type of stainless steel can be subjected to heat treatment to achieve high strength and hardness. It is frequently utilized in aerospace components, nuclear reactor parts, and high-performance applications. These are just a few examples of the stainless steel flats available in the market. The selection of a specific type depends on the particular requirements of the application, such as corrosion resistance, strength, and durability.

- Q: What are the different grades of stainless steel flat?

- Stainless steel flat is available in various grades, each with its own unique properties and characteristics. The most commonly used grades of stainless steel flat include 304, 316, and 430. Grade 304 stainless steel flat is the most widely used and versatile type. It contains 18-20% chromium and 8-10.5% nickel, which gives it excellent corrosion resistance and durability. This grade is commonly used in kitchen appliances, food processing equipment, and architectural applications. Grade 316 stainless steel flat is known for its superior corrosion resistance, especially in harsh environments. It contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, which enhances its resistance to pitting and crevice corrosion. Grade 316 is often used in marine environments, chemical processing plants, and medical equipment. Grade 430 stainless steel flat is a ferritic grade that contains 16-18% chromium. It is less corrosion resistant than grades 304 and 316 but offers good heat and oxidation resistance. Grade 430 is commonly used in automotive trim, appliances, and decorative applications. Other grades of stainless steel flat include 201, 202, 301, 302, and 304L, each with its own specific chemical composition and properties. The choice of grade depends on the intended application, budget, and required corrosion resistance. It is essential to select the appropriate grade of stainless steel flat to ensure optimum performance and longevity of the material in its intended environment.

1. Manufacturer Overview

| Location | Anhui,China |

| Year Established | 2003 |

| Annual Output Value | Above US$16 Million |

| Main Markets | South Korea;Japan; Europe;ASEAN;India |

| Company Certifications | ISO 9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 70% |

| No.of Employees in Trade Department | 160 People |

| Language Spoken: | English;Chinese;Japanese;Korea |

| b) Factory Information | |

| Factory Size: | Above 300,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Stainless Steel Fittings TP304

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 10000 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords