stainless steel 316 welded pipe fittings elbow

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of stainless steel 316 welded pipe fittings elbow:

In the piping system, the elbow is to change the direction of pipe fittings. It is divided by the angle, there are three most commonly used in 45° and 90° 180°, and according to project ,the other needs other non-normal 60° angle bend. Elbow of the material includes cast iron, stainless steel, alloy steel, forging iron, steel, nonferrous metals and plastics, etc.

2、Main Features of the stainless steel 316 welded pipe fittings elbow:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

•Reasonable price

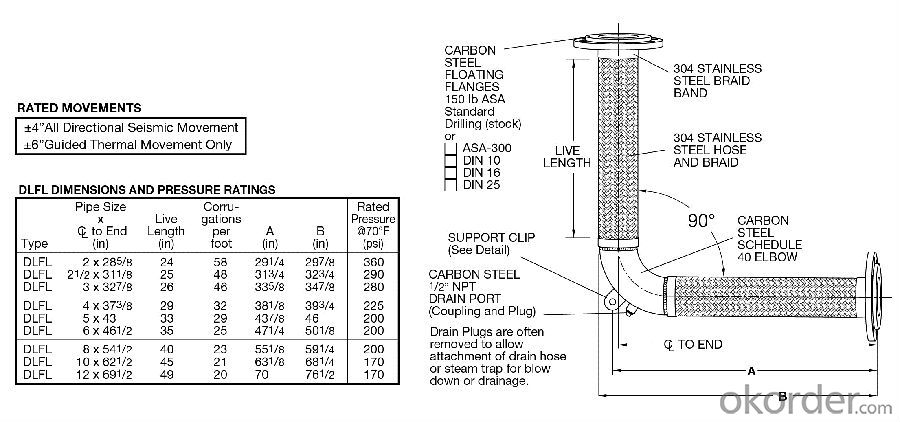

3、Stainless steel 316 welded pipe fittings elbow images:

4、stainless steel 316 welded pipe fittings elbow Specification:

| Products | pipe fittings elbows, bends,tees, reducers caps |

| Size | 1/2" - 48" |

| Wall thickness | Sch5-Sch160 XXS |

| Standard | ANSI, ASME API5L, OCT, GOST ,DIN and JIS, etc. |

| we can also produce according to drawings and standards provided by customers. | |

| Material | Carbon steel, alloy steel and stainless steel. |

| We can produce according to materials appointed by consumers. | |

| Packaging | Plywood Cases,plywood pallet, plastic bag or as customers' requirement |

| Surface Treatment | Shot blasted, rust-proof black oil |

| Others | 1.Special design available according to your drawing. |

| 2.anti-corrosion and high-temperature resistant with black painting | |

| 3. All the production process are made under the ISO9001:2008 strictly. | |

| 4. A conformity rate of ex-factory inspection of products. | |

| Delivery Time | 10-60 days |

5、FAQ of Stainless steel 316 welded pipe fittings elbow:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: What grease should be used when tapping stainless steel?

- Stainless steel, alloy steel, iron, copper and aluminum are applicable. G-2 stainless steel tapping oil Brown special stainless steel, high strength alloy steel and other hard materials tapping oil, suitable for all kinds of difficult tapping, tapping, die processing, extreme pressure antiwear performance is outstanding, with excellent performance to protect the knife.

- Q: The difference between stainless steel 201 and 204

- This product performance 04 corrosion resistance, stamping performance is better than the 01,04 in the complex environment, need strong resistance to corrosion for 01 place, environmental requirements are not very high, or the stainless steel demand is not high, the price is 04, much higher than the price of 01, according to the use of the environment, making the product quality requirements to select suitable materials

- Q: How about a small hole in a stainless steel bucket?

- Waste toothpaste, metal skin cut into the corresponding shape, cleaned and polished rough;

- Q: What paint does stainless steel spray?

- Stainless steel, aluminum, aluminum alloy, galvanized sheet, copper and other surface spray paint is a special requirement, general paint spray on it will appear the whole piece or sporadic paint phenomenon

- Q: The difference between stainless steel screen window and ordinary screen window

- Surface treatment. The bulletproof net is usually treated with electrophoretic paint, and the treated mesh is not only more beautiful, but also more rustproof. The surface of the ordinary stainless steel screen does not have any treatment!

- Q: Stainless steel kitchen cabinet? Is it suitable for household use?

- Never change, many other products with a long table color will be old, and the benefits of stainless steel is always new, wooden cabinet; when to change, will cause two pollution, and completely avoid the stainless steel cabinet, can also have a recovery value.

- Q: What is the difference between stainless steel and titanium?

- The commonly used stainless steel material is 304 1Cr18Ni9Ti including 1 chemical elements as carbon content. Cr18 refers to the content of chromium. Ni9 refers to the amount of nickel, Ti, that is what you said titanium plate of titanium. Very few in stainless steel.

- Q: Stainless steel cutlery, what harm does it do to the human body?

- Stainless steel cutlery usually contains chromium and nickel. Chromium is the product that does not rust, and nickel is a corrosion-resistant material. The long-term use of poor quality stainless steel tableware will destroy the normal human body calcium, phosphorus ratio affect the growth and development of bones, teeth and also The new supersedes the old., affect the human digestive enzyme activity, the digestive function of the stomach.

- Q: What is called oil film wiredrawing stainless steel?

- The original stainless steel wire drawing, adding oil film technology, the formation of a thin film on the surface of stainless steel, stainless steel can show that the change is very smooth, mainly beautiful, dustproof, oil, waterproof, easy to clean, take care of!

- Q: Can the stainless steel sink of the drawing surface be only used with 304 stainless steel?

- No matter 304 material, it can be made into wire drawing surface. The quality of the material directly affects the appearance of the drawing surface. Feel light, important to look at the whole, such as big brands sink bottom glue is very thin, in fact, the plate is relatively thick.At present, you buy the sink, feel light, it may be the thickness of the plate, primer thickness, noise pad thickness and other factors, with nothing to do with the material, with comfortable on the line.Wire drawing is a surface treatment process.

Send your message to us

stainless steel 316 welded pipe fittings elbow

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords