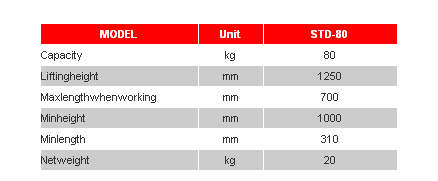

STACKER PRODUCT SERIE - Hand stacker STD

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

All products are granted CE or GS certificates by Rheinland Group. The products are widely used in the field of modern logistic. There are seven product categories and over 2000 sorts. Besides standard products, we also customizes according to your requirements.

We focus on improving our core competitiveness and grasp the trend of upsizing, intelligentizing and environmental friendly. Based on self-developement and innovation, we cooperate with scientific research institution and schools and study new products, technique and craft which are suitable for market.

Stackers and reclaimers were originally manually controlled, with no means of remote control. Modern machines are typically semi-automatic or fully automated, with parameters remotely set. The control system used is typically a programmable logic controller, with a human-machine interface for display, connected to a central control system.

Other than stacking, a stacker has three basic movements:

Luffing: This is vertical movement. Stackers use either a winch mechanism with metal wire, or hydraulic cylinders, generally two. Winch mechanisms are highly reliable compared to hydraulic actuators and remain widely used, particularly in large stackers.

Travelling: The stacker moves on a rail track, which may be broad or narrow gauge, enabling it to move around the stockyard as required. For this purpose, traction motors powered by direct current (DC) are connected by bevel gears to between 12 and 22 wheels. For manual control, all the controls are in a controller's cabin above the boom conveyor or boom. Modern stackers can be controlled remotely.

Slewing: This is rotation of the stacker around its central axis to align or place the stockpile where required. This works mostly by a slew pinion that rotates around a slew base. This type of gear assembly is called a sun and planet gear. The axles may be multiple and are driven by DC-powered axle motors which transmit the torque via bevel or helical gears.

The conveyor belts used in stackers may be made of fabric or metal wire, depending upon the material to be handled. They are driven by pulleys, which in turn are driven by DC motors. The motors and gear are coupled by fluid coupling.

Most stackers are electrically powered by way of a trailing cable. There are basically two types of cable trailing: power cord rotating drum (PCRD) and control cable rotating drum (CCRD). Pendulum adjustments are made to ensure the proper alignment of these cables while the stacker is travelling.

- Q: Does the shear fork lift stand belong to special equipment?

- It belongs to special equipment, the manufacturer must have special equipment production qualification "special equipment manufacturing license" to be able to produce the sale shear fork lift machine. The products of the manufacturer without relevant documents are not eligible.

- Q: How do you jump to the wall and jump to the wall?

- Hello, this is A question that I have also encountered, not by these three keys, but by right and A, and then by space. Hope to help you.

- Q: What is the difference between elevator and elevator

- Lifting platform refers to the above is a platform of lifting machinery, elevator is the work belt bucket elevator machinery, such as building used to transport personnel and the content of the elevator, generally called.

- Q: The single fork hydraulic lift platform

- If you don't have a hydraulic lock on the oil circuit, it should be,I hope my answer will help you

- Q: How is the lifting handle of the universal knee-milling machine very tight

- You're talking about a tight lock or a handle.I hope my answer will help you.

- Q: How is the small electric shearing fork lift designed

- Shear fork lift platform is mainly used in the logistics industry, production lines, lifting, loading and unloading goods to floor between basement, can also be used to lift stage, lifting work station, etc. The product has a stable structure, low failure rate, reliable operation, safe and efficient and easy to maintain. The fixed platform shall be equipped with the requirements of use, and the attached devices shall be configured for any combination such as the safety protection device of the platform. Electrical control mode; Work platform form; Dynamic form; Walking actuators and so on. The correct choice of all kinds of configuration, the function of the lifting platform can be maximized, the best use effect is obtained.

- Q: What device is better to design a platform that is 1 square meter or so?

- Hello, we are jinan Kowloon hydraulic machinery manufacturing co., LTD., which produces elevators,

- Q: The home is decorated, make a tatami mat the platform should pay attention to what aspect?

- The second is to notice whether the product has a secure clamping system. Most of the products on the market are mechanical clamping system, which is low in safety, and the system is too resistant to it. Best choice is the electronic control system, because it will through the electronic system induction to the resistance changes, more than a certain value will stall, electric and automatic recovery (electronic resistance setting values are very sensitive, high security), such as task of children. The third is, of course, the manufacturer and the brand, the good manufacturer and the brand make the product more reliable, which is not to be said in detail.

- Q: Can the stepping motor drive the hydraulic platform?

- Are you a driver for this motor? But the normal step motor is only for torque, step Angle, phase number, not for rotational speed; It may be a servo motor or torque motor, and if the speed is low it is the possibility of torque motors. In addition, you can measure the current, voltage or waveform below.

- Q: What hydraulic cylinder is used

- As long as the hydraulic cylinder reaches the required height.I hope my answer will help you.

Send your message to us

STACKER PRODUCT SERIE - Hand stacker STD

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords