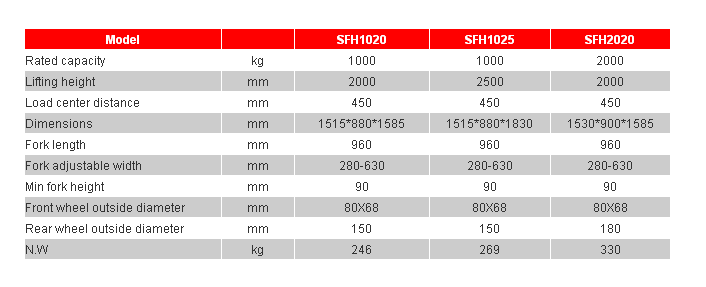

STACKER PRODUCT SERIE - Double masts hand stacker SFH series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

All products are granted CE or GS certificates by Rheinland Group. The products are widely used in the field of modern logistic. There are seven product categories and over 2000 sorts. Besides standard products, we also customizes according to your requirements.

We focus on improving our core competitiveness and grasp the trend of upsizing, intelligentizing and environmental friendly. Based on self-developement and innovation, we cooperate with scientific research institution and schools and study new products, technique and craft which are suitable for market.

Stackers and reclaimers were originally manually controlled, with no means of remote control. Modern machines are typically semi-automatic or fully automated, with parameters remotely set. The control system used is typically a programmable logic controller, with a human-machine interface for display, connected to a central control system.

Other than stacking, a stacker has three basic movements:

Luffing: This is vertical movement. Stackers use either a winch mechanism with metal wire, or hydraulic cylinders, generally two. Winch mechanisms are highly reliable compared to hydraulic actuators and remain widely used, particularly in large stackers.

Travelling: The stacker moves on a rail track, which may be broad or narrow gauge, enabling it to move around the stockyard as required. For this purpose, traction motors powered by direct current (DC) are connected by bevel gears to between 12 and 22 wheels. For manual control, all the controls are in a controller's cabin above the boom conveyor or boom. Modern stackers can be controlled remotely.

Slewing: This is rotation of the stacker around its central axis to align or place the stockpile where required. This works mostly by a slew pinion that rotates around a slew base. This type of gear assembly is called a sun and planet gear. The axles may be multiple and are driven by DC-powered axle motors which transmit the torque via bevel or helical gears.

The conveyor belts used in stackers may be made of fabric or metal wire, depending upon the material to be handled. They are driven by pulleys, which in turn are driven by DC motors. The motors and gear are coupled by fluid coupling.

Most stackers are electrically powered by way of a trailing cable. There are basically two types of cable trailing: power cord rotating drum (PCRD) and control cable rotating drum (CCRD). Pendulum adjustments are made to ensure the proper alignment of these cables while the stacker is travelling.

- Q: Does the fixed hydraulic platform need to submit to the specification requirement

- There is no clear regulation of hydraulic lift and hydraulic platform in China, which means that you can also do it without testing. Local regulations may be different. Also, if you check, you are going to the local quality and technical supervision bureau. Should go to the special branch to register, apply for installation, after installation is finished again ask them to check the acceptance of the check. There is a fee for it. And it will be checked every year.

- Q: The hydraulic platform is compared with the normal lift platform

- Double protected leg structure, work safer, and can be close to the working face lift. The machine is the answer for you!!

- Q: What about the platform of southworth?

- As far as I know, at present in domestic, the lifting platform with voss is still a better public praise manufacturers, has a manufacturing license certificate and installation license certificate, old brand, trusted. Businesses are now registered in Shanghai and manufacturing plants in Shanghai.

- Q: There are several reasons for the hydraulic cylinder oil leak on the elevator

- Oil cylinder in and out tubing joint cracking; (I've seen a lot of this in practice.) 2) the sealing damage of the piston rod with the piston rod is caused by the pull of the piston cylinder. 3) cooperate with cylinder liner piston rod out end seal is damaged, this is caused by long-term use of seal aging more, also has a lot of end cover on is too hard to seal extrusion is damaged, there is a lot of domestic manufacturer of hydraulic cylinder design is not reasonable cause (mostly in order to save costs)

- Q: What happened to the rise and fall

- The motor is missing (the motor is not moving, and there is a buzzing sound) to check the circuit breaker and the electrical wiring. The drop valve is open when the drop button is released, and the voltage meter is used to check if the valve has electricity. If there is no electricity, check the line and troubleshoot it. If there is electricity, the valve itself is out of fault. The slide valve must be clean and flexible. The overflow valve is adjusted to the relief valve. Under 100% rated load to adjust the oil level is too low, the oil pump hydraulic oil filled up at a empty absorption, oil absorption filter clogging, clean filter, oil leakage, check the suction tubing and connectors; Tighten the joint.

- Q: There are several categories of mobile elevators

- Knowledge of mobile elevators is almost there. Mobile hoist considering the mobile convenience more considering the high stability, wide operating platform and high bearing capacity, can make the work high above the range larger, more wide, many people work at the same time. Improving the efficiency of the work is a safe place for people.

- Q: Operation and attention of electric elevating platform car?

- When the working pressure of the platform is too high or the noise is abnormal, the inspection should be stopped immediately so as not to seriously damage the platform. For general failures, see (troubleshooting and troubleshooting); G, the wind should not be greater than 5 when used, and the machine should not be used in thunderstorm. Note: A, non-electric professional personnel should not disassemble the electrical appliances at will, in case of electric shock or mistake. B: the platform should be hoisted on the platform when the platform is being repaired under the platform. In case the platform suddenly drops, causing casualties;

- Q: Do you have a personal elevator with hydraulic platform

- Hydraulic platform itself is not flat layer device, the upper and lower limit is oil cylinder and the mechanical structure limits. Platform only "motor" "stop" "up" "down" button. The safety of the sheared platform can also be shaken when it starts and stops, without the thought preparation. In different floor installed several travel switch, electric cabinet, become automatic stop, hardware does not need how many money, the line a little trouble. Can do it. Just installed is not good

- Q: Put a large beaker of water on a horizontal platform and put a light glass upside down in the water

- Rise slowly lifts A certain height, because the process is slow cooling can in time, and the environment temperature balance, and can be regarded as constant temperature, the glass is immersed in the water depth increases, the gas pressure increase, to A.

- Q: What is the main shaft of the horizontal milling machine

- Horizontal movements of spindle of the milling machine is driven by servo motor, each after a pair of tooth belt pulley deceleration, to the longitudinal, transverse and vertical feed movement of the ball screw to achieve three direction.

Send your message to us

STACKER PRODUCT SERIE - Double masts hand stacker SFH series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords