Ballasted Solar Mounting Systems - TT-TK-H02 Solar Panel Mounting System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 50万套 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

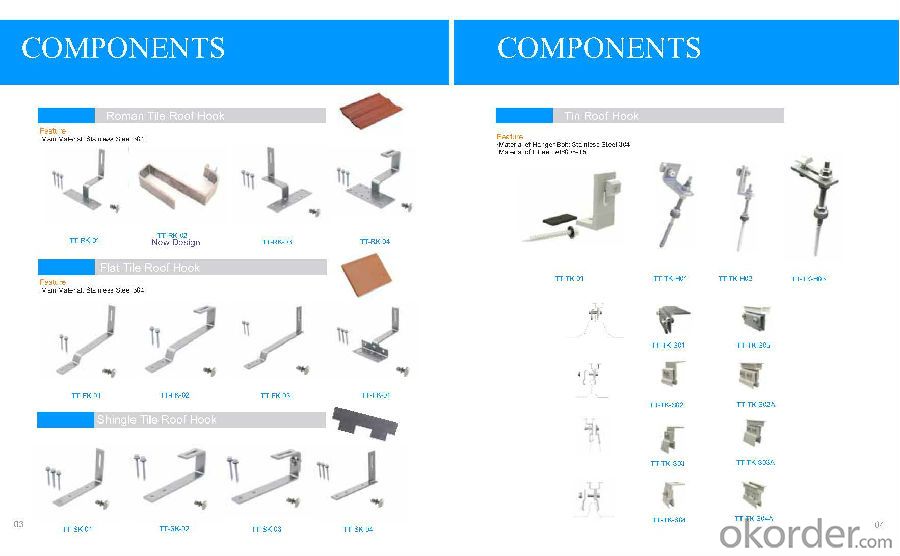

PV Mounting brackets are special solar photovoltaic systemfor placing, installing, fixing the solar panel design. Generally materials arealuminum, steel structure, stainless steel. PV mounting products at groundmounting system, flat roof mounting system, adjustable angle roof rack system,inclined roof rack system, column bracket system.

The Ground Mounting System including concret basement sysytemand steel pipe sysytem, Titanergy provides total solution for flat or pitchedroof with patent products.On the basis of the given project data, specificnational standards and guidelines, Titanergy will calculate the completestructural analysis and create a complete project plan to make sure reliablestructural safety.We provide high quality HDG steel and aluminum products forthe ground mounting sysytem,witch can make sure the security and durability ofthe project.

Features and Advantages

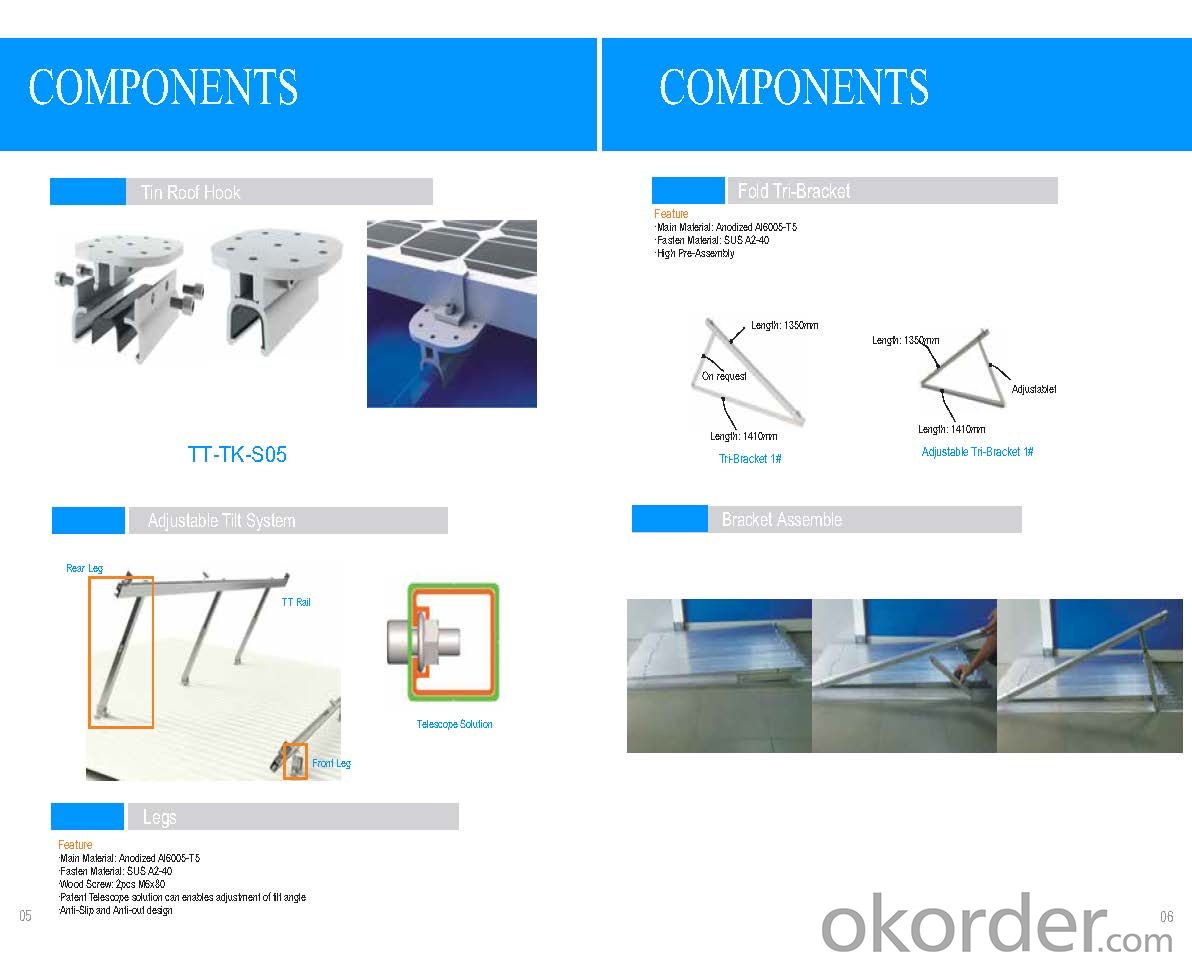

n The rail bracket is easy to install, just use simple tools(eg, Allen wrench) can be easily installed. Rail connecting member can freelyadjust the length, the stent may be pre-installed on the roof, and thenappropriately adjusted according to the size of the solar panel.

n The combination of strong, aluminum rails and card blocks fora variety of venues and a variety of materials roofs (such as metal, ceramicand other kinds of tile surface)

n Component compatibility, and rail can meet PV modules fromdifferent manufacturers.

n accuracy, the length of the rail to the nearest millimeter,the construction process, not because of the length is too long or too shortfor the second cut.

n flexible assembly, rail hooks can adjust the spacing modulearray and tile has been installed successfully address the uneven roofconstruction led to difficult problems.

n design standards, product design and development process instrict accordance with GB, the German standards and other internationalstandards to ensure products reach the world advanced level.

n Quality assurance, the stent main material is high-qualityaluminum and stainless steel, effectively prevent corrosion of oxidation.Products can be recycled, reducing environmental pollution.

n Carried out strictly according to the current specificnational standards

n Perfectly optimized components and complete structuralanalysis for the sysytem

n High corrosion resisitance ensure the stability and highdurability

n Total test and certification make sure the high quality ofthe products

n Maximum pre-assembled in factory,quick mounting onsite,timesaving

10-year durability warranty

Technical Data

n Design Period:25 years

n Installation Site: Open area

n Array Angle:10°~60°

n ModuleType:Framed or unframed

n Material:Q235B,Al 6063-T5,Al 6005-T5,StainlessSteel A2-70

n Coating:HDG/Anodised

- Q: Can a solar mounting system be installed on a rooftop with a built-up roof?

- Yes, a solar mounting system can be installed on a rooftop with a built-up roof. The mounting system is designed to be compatible with various roof types, including built-up roofs. Proper installation techniques and considerations for the roof's structural integrity and waterproofing will need to be followed to ensure a successful installation.

- Q: How does the orientation of a solar mounting system affect its performance?

- The orientation of a solar mounting system greatly affects its performance. The system's orientation determines the angle at which the solar panels are positioned relative to the sun, which directly impacts the amount of sunlight they receive. By maximizing the exposure to sunlight, the system can generate more electricity. The ideal orientation depends on the geographical location and its latitude, with panels typically angled to face south in the northern hemisphere and north in the southern hemisphere. Adjusting the orientation can optimize the system's efficiency, maximizing energy production and overall performance.

- Q: How does a solar mounting system affect the roof's waterproofing?

- A solar mounting system can affect the roof's waterproofing by penetrating the surface with bolts or brackets used to secure the panels in place. These penetrations can potentially create areas where water can seep through and compromise the roof's integrity. However, when installed correctly with proper waterproofing measures, such as flashing and sealants, the impact on waterproofing can be mitigated, ensuring the roof remains watertight.

- Q: Can a solar mounting system be installed on a tent or canopy?

- Yes, a solar mounting system can be installed on a tent or canopy. This allows for portable and off-grid power generation, making it an ideal solution for outdoor events, camping, or emergency situations.

- Q: Can a solar mounting system be installed on a rooftop with a corrugated metal roof?

- Yes, a solar mounting system can be installed on a rooftop with a corrugated metal roof. There are specific mounting systems designed for corrugated metal roofs that allow for secure installation of solar panels. These systems typically include clamps or brackets that attach to the ribs of the metal roof, providing a stable and durable foundation for the solar panels.

- Q: Are there any specific requirements for installing solar mounting systems in areas with high winds?

- Yes, there are specific requirements for installing solar mounting systems in areas with high winds. These requirements include using robust and durable mounting components, such as heavy-duty frames and fasteners, to withstand the strong wind forces. Additionally, the system should be properly anchored and secured to provide stability and prevent any potential damage or dislodging in high wind conditions. Regular inspections and maintenance are also necessary to ensure the system remains secure and continues to function optimally in areas with high winds.

- Q: What materials are commonly used in solar mounting systems?

- Common materials used in solar mounting systems include aluminum, steel, and stainless steel. These materials are chosen for their durability, strength, and resistance to corrosion, ensuring that the mounting system can withstand various weather conditions and last for a long time. Additionally, some mounting systems may also incorporate plastics or composite materials to provide additional support and flexibility.

- Q: What is the full support system

- The biggest advantage of the construction of the stent method is the need for large-scale lifting equipment, the drawback is the construction of the stent template consumption, long duration, the mountain bridge and high pier has great limitations.

- Q: Are there adjustable tilt angle options for solar mounting systems?

- Yes, there are adjustable tilt angle options available for solar mounting systems. These options allow for customization of the tilt angle of the solar panels to optimize energy production based on the specific location and seasonal changes in the sun's position.

- Q: Can a solar mounting system be installed on a slate roof?

- Yes, a solar mounting system can be installed on a slate roof. However, special care and expertise should be taken during the installation process due to the delicate nature of slate roofing. It is important to hire professionals who are experienced in working with slate roofs to ensure the integrity of both the roof and the solar system.

Send your message to us

Ballasted Solar Mounting Systems - TT-TK-H02 Solar Panel Mounting System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 50万套 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords