Multi-Junction Solar Cells for Sale:Solar Cell Monocrystalline and Polycrystalline 156 with ISO9001/ISO14001/TUV/UL

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Packaging& Delivery | |

| Packaging Detail: | standard export package suitable for long seavoyage and tough handling |

| Delivery Detail: | 10-25 days depending on order quantity |

Specifications

solar cell for solar panel

1.16.8%~18.25% high efficiency

2.100% checked quality

3.ISO9001/ISO14001/TUV/UL

4.fast lead time

Our Advantage

1. High efficiency and High power.

2. Long-term electrical stability.

3. Lowest price and Fastest delivery.

4. Good quality and good service.

5.Bulk supply

6. Good Warranty

7.Big Sale

8.High quality

9.More than 35 years on the lifetime.

10 DHL/Fedex/UPS/TNT/EMS etc

Product Description

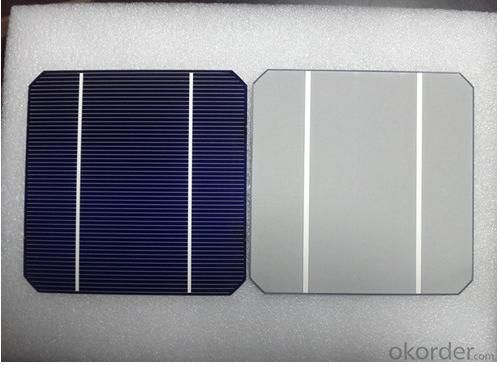

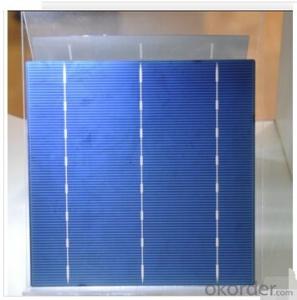

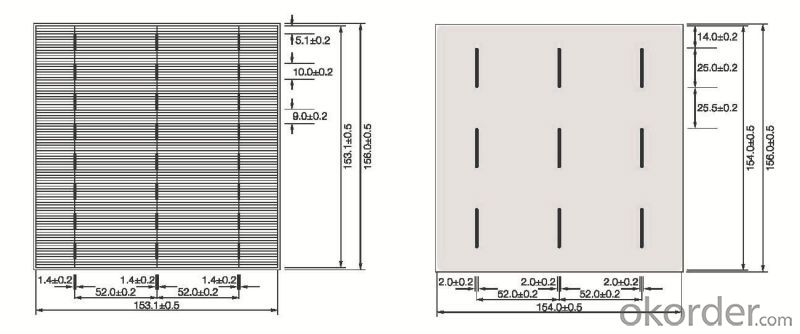

POLY6'(156*156) Multicrystalline Silicon solar celle

Diagonal: 220mm±0.5mm

Thickness(Si): 200±20 μm

Dimension: 156mm×156mm±0.5mm

Front(-) Back(+)

Blue anti-reflecting coating (silicon nitride); Aluminum back surface field;

1.5mm wide bus bars; 2.0mm wide soldering pads;

Distance between bus bars: 51mm. Distance between bus bars :51mm.

poly 156 cell Electrical Characteristics( solar cell for solar panel )

| Efficiency(%) | 18 | 17.8 | 17.6 | 17.4 | 17.2 | 16.8 | 16.6 | 16.4 | 16.2 | 16 | 15.8 | 15.6 |

| Pmpp(W) | 4.33 | 4.29 | 4.24 | 4.19 | 4.14 | 4.09 | 4.04 | 3.99 | 3.94 | 3.9 | 3.86 | 3.82 |

| Umpp(V) | 0.53 | 0.527 | 0.524 | 0.521 | 0.518 | 0.516 | 0.514 | 0.511 | 0.509 | 0.506 | 0.503 | 0.501 |

| Impp(A) | 8.159 | 8.126 | 8.081 | 8.035 | 7.99 | 7.938 | 7.876 | 7.813 | 7.754 | 7.698 | 7.642 | 7.586 |

| Uoc(V) | 0.633 | 0.631 | 0.628 | 0.625 | 0.623 | 0.62 | 0.618 | 0.617 | 0.615 | 0.613 | 0.611 | 0.609 |

| Isc(A) | 8.709 | 8.677 | 8.629 | 8.578 | 8.531 | 8.478 | 8.419 | 8.356 | 8.289 | 8.22 | 8.151 | 8.083 |

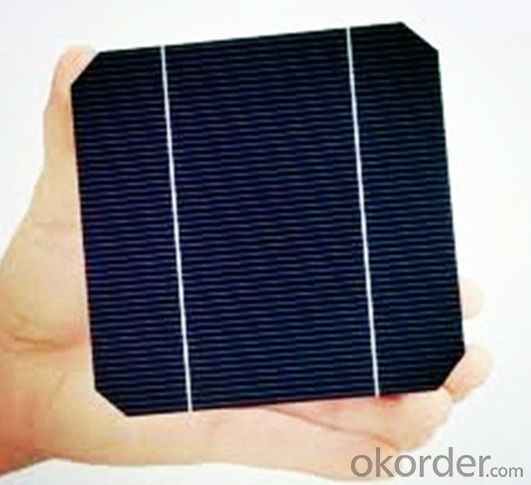

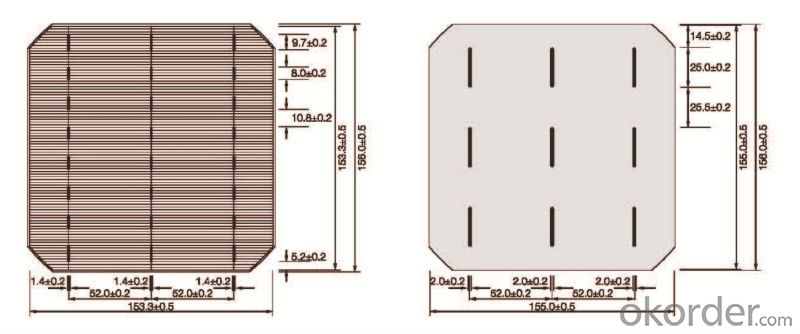

MONO6'(156*156) Monocrystalline silicon solar cell

Thickness(Si): 200±20 μm

Dimension: 156mm×156mm±0.5mm

Diagonal: 200mm±0.5mm (round chamfers)

Front(-) Back(+)

Blue anti-reflecting coating(silicon nitride); Aluminum back surface field;

1.3mm wide bus bars; 2.0mm wide soldering pads;

Distance between bus bars: 52mm. Distance between bus bars :52mm.

mono 156 Electrical Characteristics( solar cell for solar panel )

| Efficiency(%) | 20 | 19.2 | 19 | 18.8 | 18.6 | 18.4 | 18.2 | 18 | 17.8 | 17.6 | 17.4 | 17.2 |

| Pmpp(W) | 4.59 | 4.54 | 4.49 | 4.45 | 4.4 | 4.35 | 4.3 | 4.26 | 4.21 | 4.16 | 4.11 | 4.08 |

| Umpp(V) | 0.541 | 0.54 | 0.538 | 0.535 | 0.533 | 0.53 | 0.527 | 0.523 | 0.519 | 0.518 | 0.516 | 0.514 |

| Impp(A) | 8.484 | 8.407 | 8.346 | 8.318 | 8.255 | 8.208 | 8.159 | 8.145 | 8.112 | 8.031 | 7.95 | 7.869 |

| Uoc(V) | 0.64 | 0.639 | 0.638 | 0.637 | 0.636 | 0.634 | 0.632 | 0.631 | 0.63 | 0.629 | 0.628 | 0.627 |

| Isc(A) | 8.972 | 8.959 | 8.936 | 8.912 | 8.875 | 8.83 | 8.805 | 8.787 | 8.775 | 8.695 | 8.615 | 8.535 |

FAQ

1, What’s price per product ?

A: It’s depends on the quantity, delivery date and payment terms of the order. We can talk further about the detail price issue. Our products is high quality with lower price level.

2, How to make payment?

We accept T/T or L/C.

3, What is your lead time?

Generally 1-5 weeks depends on the order quantity and your specific requirements.

4, Can you do OEM for us?

Yes, we can.

5, How do you pack your products?

We have rich experience on how to pack the panels to make sure the safety on shipment when it arrives at the destination.

With the reduction of non-renewable energy sources, environmental pollution is worsening; people gradually increased the demand for renewable energy. Solar energy is a form of renewable energy, with rich resources and environmental advantages of clean, so that the solar cell has become the focus of research. Thin film solar cell price is low. The thin film solar cells with its low price, lightweight, low consumables and so much good low light response have obtained many researchers’ attention.

Brief introduction of Thin Film Solar Cell

First need to define the scope of the thin film solar cell, the solar cell is the first generation of single crystal or polycrystalline silicon cells, a second generation solar cells using a material having a large absorption coefficient, thickness of the cell not thick enough to absorb sunlight, so called thin film solar battery. Depending on the light-absorbing material, a common classification of thin film solar cells is: cadmium telluride (CdTe), copper indium gallium selenide (CIGS), dye-sensitized (DSSC) and organic polymers (OPV) solar cells. Various types of batteries are also being studied preparation process to reduce costs, so each type of cell production method is not unique.

Thin film solar cell is to be able to charge the battery through the solar thin film, which is generally the same with thin film thickness, usually black or dark. Mainly used in construction, military, travel, defense, power supply and other purposes.

Advantages of Thin Film Solar Cell

1. In low light the extent of its power generation performance is very good.

2. In the case of the same light intensity as compared with other batteries and less power loss.

3. The thin film solar cell has a very good power temperature coefficient.

4. The light transmission and generation capacity, only a small amount of silicon feedstock and the production time.

5. Internal short-circuit problem does not occur.

6. Volume thin film solar cells, generally raw materials, building materials, and can be integrated with the application.

- Q: How do solar cells handle partial shading?

- Solar cells handle partial shading by using bypass diodes. These diodes allow the current to bypass the shaded area, ensuring that the rest of the solar cell continues to function efficiently. By redirecting the current, the solar cells can still generate power even if some parts are shaded, minimizing the impact of partial shading on overall performance.

- Q: Can solar cells be used to power an entire household?

- Yes, solar cells can be used to power an entire household. By installing a sufficient number of solar panels and utilizing battery storage systems, solar cells can generate enough electricity to meet the energy needs of a household. This allows for the reduction or elimination of reliance on the traditional electrical grid, resulting in lower energy costs and a more sustainable and environmentally friendly power source.

- Q: How do solar cells impact the local economy?

- Solar cells have a positive impact on the local economy as they create jobs, stimulate investment, and reduce energy costs. The installation, maintenance, and manufacturing of solar cells require skilled labor, thus creating employment opportunities within the community. Additionally, the growth of the solar industry attracts investments in infrastructure and research, fostering economic development. Moreover, solar energy helps lower electricity bills for businesses and households, freeing up funds that can be spent on other local goods and services, thereby boosting economic activity.

- Q: How do solar cells handle electromagnetic radiation?

- Solar cells are designed to handle electromagnetic radiation by converting it into usable electrical energy. The materials within the solar cells absorb photons from the sunlight, which in turn generates an electric current. This process effectively harnesses the energy from the electromagnetic radiation and allows solar cells to produce clean and renewable electricity.

- Q: What is the role of monitoring systems in solar cell systems?

- The role of monitoring systems in solar cell systems is to continuously monitor and analyze the performance and efficiency of the solar panels. It allows for real-time tracking of the energy production, detecting any malfunctions or abnormalities, and identifying potential issues that may affect the overall system performance. This data helps in optimizing the efficiency of the solar cell system, ensuring maximum energy generation, and enabling timely maintenance and repairs. Monitoring systems also provide valuable insights for system optimization, energy consumption analysis, and performance evaluation.

- Q: Can solar cells be used in desert environments?

- Yes, solar cells can definitely be used in desert environments. In fact, solar energy is particularly well-suited for such locations due to the high levels of solar radiation and clear skies typically found in deserts. The arid climate and ample sunlight make desert regions ideal for harnessing solar power, allowing solar cells to generate a significant amount of electricity.

- Q: What is the role of solar cells in powering off-grid cabins?

- The role of solar cells in powering off-grid cabins is to harness energy from the sun and convert it into electricity. These cells, also known as photovoltaic cells, absorb sunlight and generate a direct current (DC), which is then converted into alternating current (AC) through an inverter. This AC power is used to operate appliances, lighting, and other electrical devices in off-grid cabins, providing a sustainable and renewable source of energy without the need for a traditional power grid connection.

- Q: Can solar cells be used for powering remote research stations?

- Yes, solar cells can be used for powering remote research stations. Solar cells, also known as photovoltaic cells, convert sunlight into electricity, making them an ideal and sustainable power source for remote locations. Solar panels can be installed at the research station to capture sunlight and generate electricity, which can then be stored in batteries for use during periods of low sunlight or at night. This enables the research station to operate independently of traditional power grids, reducing reliance on fossil fuels and providing a clean and renewable energy solution.

- Q: How are solar cells installed on rooftops?

- Solar cells are typically installed on rooftops using a mounting system that secures the panels in place. This involves attaching metal brackets or rails onto the roof, which act as the support structure for the solar panels. The panels are then placed onto these brackets and secured using clamps or screws. The installation process requires careful positioning and alignment to ensure maximum sunlight exposure for efficient energy generation.

- Q: Can solar cells be used for powering electric vehicles in motion?

- Yes, solar cells can be used to power electric vehicles in motion. Solar panels can be installed on the roof or body of the vehicle to capture sunlight and convert it into electricity, which can then be used to power the vehicle's electric motor. While the amount of power generated by solar cells may not be sufficient to completely run the vehicle, it can supplement the battery's charge and increase the overall range of the electric vehicle.

Send your message to us

Multi-Junction Solar Cells for Sale:Solar Cell Monocrystalline and Polycrystalline 156 with ISO9001/ISO14001/TUV/UL

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords