Sodium Naphthalene Sulfonate Formaldehyde Used in Concrete

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Sodium Naphthalene Sulfonate Formaldehyde Used in Concrete

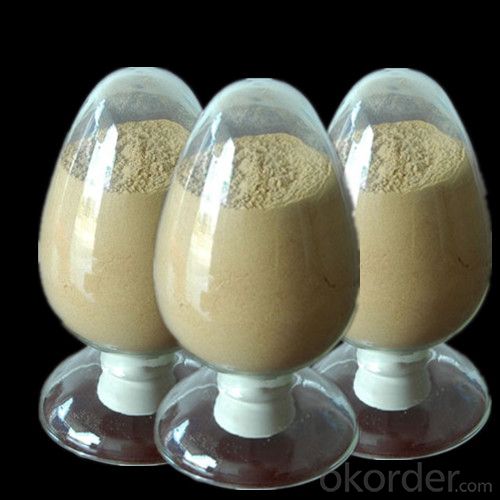

Sodium Naphthalene Sulfonate Formaldehyde has the advantage of high water reducing ratio, non-delayed coagulation, non-air entraining and strong adaptability. It can improve the workability of concrete to a large extent so as to reduce the water consumption for blending. Meanwhile, it can improve the strength of concrete. As the main master batch of various kinds of compound concrete admixture, it could also produce series products of concrete admixture which can be suitable for all kinds of project requirement through compounding with other kinds of admixture. This product can contribute to the improvement of project quality and construction efficiency and the reduction of construction cost. It can also improve the process of works.

Items | Specifications | ||

Type | FN1 | FN2 | FN3 |

Visual appearance | Dark Brown Power | Light Brown Powder | Light Brown Powder |

Fineness(0.315mm remains),% | ≤15 | ≤15 | ≤15 |

Solid content, % | ≥92 | ≥92 | ≥92 |

pH value(20℃)(5% solution) | 7-9 | 7-9 | 7-9 |

Sodium sulfate content,% | ≤5.0 | ≤10 | ≤18 |

Chloride content,% | ≤0.3 | ≤0.4 | ≤0.6 |

Cement paste fluidity, mm | 230 | 210 | 200 |

Water reducing rate, % | 15-27 | 15-25 | 14-22 |

Steel-bar corrosion | None | None | None |

Sodium Naphthalene Sulfonate Formaldehyde Scope of application

1. It can be applied to cast-in-situ, prefabricating, prestressed steel concrete and fly ash concrete, etc.

2. It is suitable for configurating early strength, high strength, high impermeability, self-fcompaction and high durability concrete.

3. It can be applied to self-cured and vapor-cured concrete project and products.

4. It can used to configurate C30-C60 concrete and also can configurate C70-C80 high strength concrete if the dosage is added and mineral admix-ture is added to the concrete.

Sodium Naphthalene Sulfonate Formaldehyde Main performance and characteristics

1. NSF is suitable to make high flowing concrete, commercial concrete, pumping concrete, precast and reinforced concrete.

2. NSF can be used to make C10-C60 concrete with slump loss between 50mm and 70mm, or C60 concrete with slump between 180mm and 220mm

3. NSF can be used as raw material to compound accelerator, retarder, anti-freezing agent and pumping aid to satisfy requirements from different construction projects, techniques, materials and environmental temperatures.

4. NSF is compatible with Portland Cement, Portland Slag cement, Fly-ash Cement, Portland Pozzolanic Cement etc.

Sodium Naphthalene Sulfonate Formaldehyde usage

1. As the requirement of engineer,the dosage can be adjusted after testing.

2. It can be put into blender with minxing water, If it is added later or added before concrete pouring and is mixed for a moment,the plasticizing effect could be better.

Packaging, transport and storage

1. The powder product is packed with 25 ± 0.25kg laminating woven bag. Packaging specifications should meet the user requirements.

2. Powder product is easy to soluble in water, liquid dilution will affect the effective concentration of the product, transport and storage should be noted that the anti-leaching, avoid moisture, direct sunlight, kept under seal and away from open flame at the room temperature or during the transport.

3. In the case of good storage conditions, valid period is three years. If it is more than 3 years, rechecking is needed for using continually.

Send your message to us

Sodium Naphthalene Sulfonate Formaldehyde Used in Concrete

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords