Snapdeal Packaging Tape - Masking Film Yellow Resistance High Temperature

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 30000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

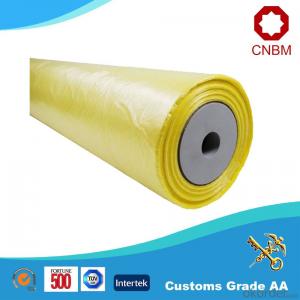

Masking Film Yellow Resistance High Temperature

1. Structure of Masking Film Description

Masking Film is of HDPE film and masking tape. Pretaped with Masking Tape, which is sunlight stable and gives the user 7-day clean removal. A convenient, pretaped plastic film which unfolds to cover and protect various surfaces while painting. Specially treated film clings to surfaces and is easy to clean up.

2. Main Features of Masking Film

Multi-Folded easy to use;

Strong and Flexible;

Sunlight stable even on glass

Indoor/outdoor painting

Competitive price

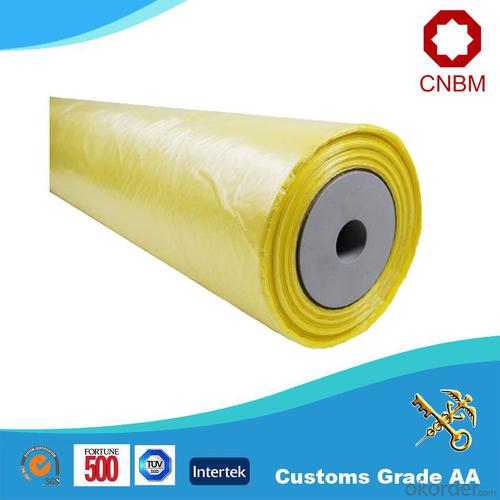

3. Masking Film Images

4. Masking Film Specification

Tape Size | Rolls/Carton | Weight/Roll(kg) | Jointing Material | Temperature Resistance |

330mm*30M | 20 | 0.12 | Crepe parer | -5—60°C |

550mm*30M | 50 | 0.17 | Crepe parer | -5—60°C |

1100mm*30M | 25 | 0.30 | Crepe parer | -5—60°C |

1400mm*30M | 10 | 0.39 | Crepe parer | -5—60°C |

5. FAQ

Q1. What is our company?

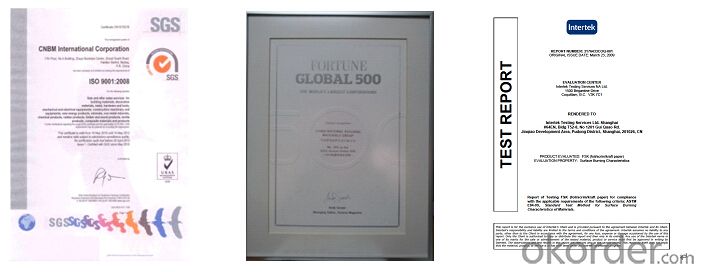

CNBM International Corporation is a state-owned company. As World Top 500 Company, we have clients from over 120 countries and overseas branches in 5 countries. We specialized in adhesive tape for over 20 years, with SGS and ISO9001 certified and Grade AA for Export.

Q2. What is the main sizes of masking film?

4mx2.5m,4mx5m, 4mx6m, 4mx8m, 4mx10m, 4mx12.5m, 2mx25m, 2mx50m

6ftx12ft, 8ftx12ft, 9ftx12ft, 10ftx20ft, 9x400ft

Q3. Packing and shipping

It is wraped by hot shrink POF film with adhesive lable. 50 rolls or 25rolls packing in to one carton.

After receiving the deposite, it will take around 20 days before shippment.

- Q: Is packaging tape easy to write on?

- Yes, packaging tape is generally easy to write on. It provides a smooth surface for writing and most pens or markers adhere well to it, allowing you to write clearly and legibly on the tape.

- Q: What are the considerations for using packaging tape on plastic packaging materials?

- When working with plastic packaging materials and using packaging tape, it is essential to keep several important factors in mind. These factors include: 1. Adhesive Compatibility: Ensuring that the adhesive used in the packaging tape is compatible with the specific type of plastic material is crucial. Different plastics have different surface properties, and they may require different adhesive formulations to ensure proper bonding. For instance, low surface energy plastics like polyethylene may necessitate a tape with a specially designed adhesive for such surfaces. 2. Strength and Durability: Plastic packaging materials come in varying thicknesses and strengths. When choosing packaging tape, it is important to consider the strength and durability required for the specific plastic material being used. The tape should be strong enough to securely hold the packaging together without tearing or breaking, thus maintaining the package's integrity during handling and transportation. 3. Temperature Resistance: Plastic packaging materials can be sensitive to temperature changes. If the package is exposed to extreme temperatures, such as heat or cold, the packaging tape should be capable of withstanding these conditions without losing its adhesive properties. Certain plastic materials may also shrink or expand due to temperature changes, which can impact the tape's adhesion. Therefore, it is important to select a tape suitable for the expected temperature range. 4. Residue and Damage: Some packaging tapes may leave behind adhesive residue or cause damage when removed from plastic packaging materials. This can pose a problem if the packaging needs to be reused or if the plastic material is susceptible to damage. By choosing a packaging tape that is designed to be easily removable or leaves minimal residue, these concerns can be mitigated. 5. Regulatory Compliance: Depending on the industry or product being packaged, there may be specific regulations and standards that must be followed. It is important to ensure that the packaging tape used complies with any applicable regulations, such as food safety standards or environmental requirements. By taking these factors into consideration, one can select the appropriate packaging tape that will effectively adhere to plastic packaging materials while also providing the necessary strength, durability, temperature resistance, and compliance with regulations.

- Q: Can packaging tape be used for sealing medical supplies or equipment?

- No, packaging tape should not be used for sealing medical supplies or equipment. Medical supplies and equipment require proper and sterile sealing to ensure the safety and integrity of the contents. Packaging tape is not designed for medical purposes and may not provide an adequate seal. It is important to use medical-grade sealing materials that meet the required standards and regulations to prevent contamination and ensure the effectiveness of the medical supplies or equipment.

- Q: What are the alternatives to packaging tape?

- There are numerous options available for securing packages or boxes instead of using packaging tape. Some of the popular choices are as follows: 1. Duct Tape: Known for its durability and ability to adhere to different surfaces, duct tape is a robust adhesive tape that serves as a viable alternative to packaging tape. 2. Masking Tape: Unlike packaging tape, masking tape possesses a lower level of stickiness. It is commonly utilized in painting or crafting projects, but can also be employed for securing packages. 3. String or Twine: A package can be secured by wrapping string or twine around the box and tying it tightly. This method is often used for packages that do not require a strong adhesive. 4. Packaging Straps: Made from plastic or polyester, packaging straps can be tightly fastened around the box to ensure secure packaging. They provide a reliable and sturdy alternative to packaging tape. 5. Adhesive Glue: For smaller packages or envelopes, adhesive glue can be used instead of packaging tape. It is crucial to select a strong glue that will securely seal the package. 6. Paper or Kraft Tape: Water-activated paper or kraft tape is commonly employed for sealing packages. The adhesive is activated by wetting the tape, resulting in a strong and secure seal. 7. Zip Ties: Zip ties, which are plastic ties, are often used for securely fastening large or heavy packages by tightly encircling the box. To determine the most suitable alternative to packaging tape, it is vital to assess the specific requirements of the package, including its size, weight, and handling needs.

- Q: What are the benefits of using silent packaging tape?

- Using silent packaging tape offers several advantages. Firstly, it guarantees a noiseless packaging experience, which is especially valuable in settings that require silence, such as offices, libraries, or other tranquil spaces. By eliminating the loud noises typically associated with regular packaging tape, silent tape helps maintain a serene and peaceful atmosphere. Secondly, employees who regularly handle packaging tasks prefer silent packaging tape. The absence of noise during the taping process reduces the risk of stress or fatigue caused by noise, contributing to a more comfortable work environment. This, in turn, can lead to increased productivity and employee satisfaction. Furthermore, silent tape is an excellent choice for businesses that prioritize customer satisfaction. When packaging items for shipment, particularly delicate or fragile ones, using silent tape ensures a professional and refined appearance. The lack of loud noise during the packaging process also prevents any potential disturbance or annoyance to customers, both during the packaging phase and upon receiving their packages. In addition, silent packaging tape is often crafted with high-quality adhesive properties, providing a secure and long-lasting seal that keeps packages intact during transit. This reduces the chances of damaged goods and the associated costs of having to resend or replace items. Lastly, silent tape is frequently made from eco-friendly materials, making it advantageous for businesses aiming to minimize their environmental impact. By opting for silent packaging tape made from recyclable or biodegradable materials, companies can align their packaging practices with their sustainability goals. In conclusion, the benefits of using silent packaging tape include noise reduction, improved employee satisfaction and productivity, enhanced customer experience, secure sealing, and eco-friendliness. By choosing silent tape, businesses can create a more efficient, pleasant, and environmentally conscious packaging process.

- Q: Is packaging tape safe for use on painted surfaces or walls?

- Packaging tape is generally safe for use on painted surfaces or walls. However, it is important to exercise caution and follow proper techniques to minimize any potential damage. When applying packaging tape on painted surfaces or walls, it is recommended to test a small, inconspicuous area first to ensure that the tape does not peel off or damage the paint. Additionally, it is advisable to remove the tape gently and slowly to avoid any paint peeling or residue left behind. If the paint is delicate or the tape has been left on for an extended period, there is a possibility that the tape may cause some minor damage, such as slight paint discoloration or removal. Therefore, it is always a good idea to handle packaging tape with care and take necessary precautions to protect the painted surfaces or walls.

- Q: Is packaging tape resistant to chemicals?

- Yes, packaging tape is typically resistant to chemicals. It is designed to withstand various substances and maintain its adhesive properties, making it an effective choice for securing packages and protecting their contents.

- Q: Can packaging tape be used for sealing plastic toolboxes?

- Yes, packaging tape can be used for sealing plastic toolboxes. Packaging tape is designed to securely seal boxes and packages, and it can be used on various materials, including plastic. It provides a strong and durable seal that can withstand normal handling and transportation. However, for long-term storage or heavy-duty use, it is recommended to use a stronger and more specialized tape, such as duct tape or strapping tape, as they offer better durability and adhesion.

- Q: Can packaging tape be used for sealing household or kitchen items?

- Certainly! Packaging tape is indeed suitable for sealing household or kitchen items. With its versatility as an adhesive tape, it is widely employed for sealing cardboard boxes. However, it can also serve the purpose of sealing numerous items found in the household or kitchen. Whether you require sealing food containers, plastic bags, or even small appliances, packaging tape guarantees a robust and reliable seal. To optimize its adhesive strength, it is crucial to ensure that the surface is both clean and dry prior to applying the tape.

- Q: Can packaging tape be used for sealing medical or laboratory containers?

- Sealing medical or laboratory containers with packaging tape is not advisable. Although packaging tape can temporarily seal general packaging, it is not intended or tested to meet the precise demands of medical or laboratory settings. To maintain airtight and sterile conditions and prevent contamination or tampering, specialized sealing methods are often required for medical and laboratory containers. These methods may involve using adhesive strips, rubber gaskets, or screw caps that are specifically designed for medical or laboratory applications. It is of utmost importance to adhere to the sealing methods and materials recommended by the manufacturer or industry standards to guarantee the integrity and safety of medical or laboratory containers.

Send your message to us

Snapdeal Packaging Tape - Masking Film Yellow Resistance High Temperature

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 30000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords