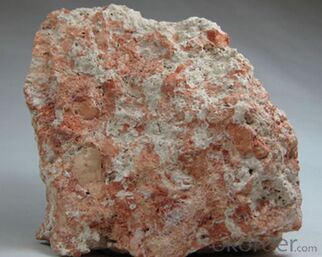

Sintered Bauxite,Gibbsite Bauxite From China !!!

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Details: | In 25KG bags;1MT/1.25MT/1.35MT bags or as your requirements. |

| Delivery Detail: | 15-30 days after contract |

Product Description

| Items | Al2O3 | Fe2O3 | B.D. | K2O+Na2O | CaO+Mgo | TiO2 |

| 88 | 88%min | 1.5%max | 3.25min | 0.25%max | 0.4%max | 3.8%max |

| 87 | 87%min | 1.6%max | 3.20min | 0.25%max | 0.4%max | 3.8%max |

| 86 | 86%min | 1.8%max | 3.15min | 0.3%max | 0.5%max | 4%max |

| 85 | 85%min | 2.0%max | 3.10min | 0.3%max | 0.5%max | 4%max |

| 83 | 83%min | 2.0%max | 3.05min | 0.3%max | 0.5%max | 4%max |

| 80 | 80%min | 2.0%max | 3.0min | 0.3%max | 0.5%max | 4%max |

| 78 | 75-78% | 2.0%max | 2.8-2.9 | 0.3%max | 0.5%max | 4%max |

Size: 0-1mm,1-3mm,3-5mm,5-8mm,8-10mm,200mesh,325mesh or as your request.

Application

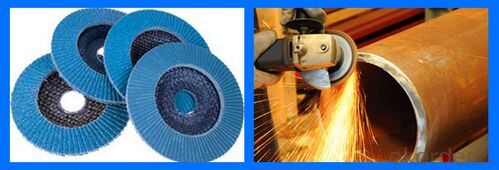

mainly used in aluminium metallurgy,aiso used in abrasive ,cement ,chemical, refractory

- Q: Which heroes know, please give the source of the data.

- From the production equipment and technology of the popular view, a ton of coke oven gas produces about 400 cubic meters, of which about 200 cubic meters of coke oven returned through the pipeline used for coking heat source, the remaining more than and 200 cubic meters was emptying, "or the lantern".

- Q: Ca3 (PO4) 2, SiO2, coke and other raw materials for the production of silica gel (SiO2? NH2O), phosphorus, phosphoric acid and CH3OH, the following process raw materials comprehensive utilizationCa3 (PO4) 2, SiO2, coke and other raw materials for the production of silica gel (SiO2? NH2O (P), phosphorus, phosphoric acid and CH3OH, the following process raw materials comprehensive utilization rate is high, less waste(1) in the reaction, which belongs to the replacement reaction is ______[optional: (I), (II) and (III), (IV), (V).(2) chemical reaction equation II under high temperature of ______; solid waste can be used for ______. CaSiO3(3) reaction to be carried out in isolation and oxygen under anhydrous conditions, the reason is ______.(4) CH3OH can be used as a fuel cell fuel in strong acid medium, the electrode reaction type anode for ______.(5) pointed out that the significance of ______. (VI) in this part of the industrial production(6) written by P H3PO4, the reaction of the ______ ______.

- The answer is: Ca3 (PO4) 2+5C+3SiO2High temperature.?3CaSiO3+2P+5CO =; production of cement, brick or building materials such as;(3) R Si, Si and HCl reaction is the reaction of SiHCl3 with hydrogen, by the reaction of the hydrolysis of SiHCl3, IV, and the generation of hydrogen and oxygen in a certain range will explode, so it must be in contact with oxygen and anhydrous conditions,Therefore, the answer is: SiHCl3 hydrolysis, while the production of H2, mixed with O2 explosion, etc.;(4) methanol oxidation reaction, under acidic conditions, methanol in the cathode of carbon dioxide and hydrogen ions, CH3OH+H2O-6e-=CO2+6H+,The answer is: CH3OH+H2O-6e-=CO2+6H+;(5) the significance of this link in industrial production: recycling of raw materials, energy saving and emission reduction,The answer is: recycling of raw materials, energy-saving emission reduction;(6) from P to H3PO4, the phosphorus and oxygen into water and phosphorus pentoxide, compound phosphate, the equation is P+O2=P2O5, P2O5+3H2O=2H3PO4,The answer is: P+O2=P2O5; P2O5+3H2O=2H3PO4

- Q: What are the uses of these early industrial iron and steel? Any difference?What kind of carbon do we eat in the middle of a long strip of carbon?

- Coke:The utility model is mainly used for blast furnace ironmaking and smelting of blast furnace for non-ferrous metals such as copper, lead, zinc, titanium, antimony, mercury, etc.. The use of coke instead of charcoal in the blast furnace has laid the foundation for the large-scale development of modern blast furnaces and is a major milestone in the history of metallurgy. In order to achieve better technical and economic indexes of blast furnace operation, the coke (metallurgical coke) must have proper chemical and physical properties. In addition to a large number of coke used in iron smelting and non-ferrous metal smelting (metallurgical coke), but also for casting, chemical, calcium carbide and iron alloy, the quality requirements are different. Such as foundry coke, generally require large size, low porosity, high fixed carbon and low sulfur; chemical gasification, strict requirements for strength, but requires good response, high ash melting point; calcium carbide and coke production requirements to improve the fixed carbon content.

- Q: How much coal can a kilogram of coal weigh?

- But now the coking industry will not only coke coke, but with coking coal, fat coal, gas coal and other coal mixed coking

- Q: What is the phosphorus content in coke

- Generally, the phosphorus content of coke is low, about 0.02%.The bituminous coal is heated to 950-1050 DEG C under the condition of air isolation

- Q: Coke and coal is one thing

- Not the same thing.Coal is often said of coal, including bituminous coal, lignite, anthracite, etc.

- Q: Braised meat burning coke, iron black layer, I do not know how to clean, please help answer

- Tomatoes to the bottom of the potNot a few good tomatoes in the pot boil, it will naturally fall.4, beer and liquor to the bottom of the potIf cooking is careful not to paste pot, the pot dish, if not easy to brush off, can pour a little wine and beer and a small amount of water (1:1:0.5 ratio) mixed cover, placed 5 minutes after it is easy to scrub clean.

- Q: 8 points will be isolated from the air to enhance the heat of coal, in addition to the main coke, but also the material listed in the following table: No.

- Carbon containing ammonia, which belongs to the inorganic carbon monoxide; although contain carbon and inorganic nature but similar, belonging to the inorganic material, so the answer is: the 7;

- Q: Distinction and distinction of cokeSoil coke, improved coke, coke machine coke do, what is the difference between

- Two, the type of coke:Coke is usually divided by use of metallurgical coke (including blast furnace coke, coke and iron alloy coke, calcium carbide and coke gasification etc.) with coke. The pressurized pulverized coal forming coal, coke carbonization etc. in the new postprocessing process called Formcoke.1, metallurgical coke, metallurgical coke is coke, coke, iron alloy coke and non-ferrous metal smelting coke for metallurgical coke collectively. More than 90% are used in blast furnace, the furnace coke often called metallurgical coke.The metallurgical coke quality standard (GB/T1996-94) made in China is the quality standard of blast furnace

- Q: How much coke is needed for a ton of iron

- 1 tons of iron: iron ore + + coke 340kg + pulverized coal injection 130kg,The process of extracting iron from iron containing minerals, mainly iron oxides, is mainly composed of blast furnace, direct reduction, smelting reduction and plasma method. From the perspective of ironmaking is metallurgy, iron rust, inverse behavior gradually mineralized, simple, pure iron reduction from iron compounds. Pure iron is not common in actual production. More iron carbon alloy.

Send your message to us

Sintered Bauxite,Gibbsite Bauxite From China !!!

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches