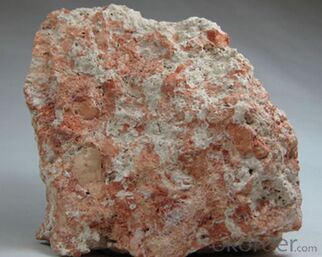

Sintered Bauxite,Gibbsite Bauxite ,Calcined Bauxite 88 From China !!!

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Details: | In 25KG bags;1MT/1.25MT/1.35MT bags or as your requirements. |

| Delivery Detail: | 15-30 days after contract |

Product Description

| Items | Al2O3 | Fe2O3 | B.D. | K2O+Na2O | CaO+Mgo | TiO2 |

| 88 | 88%min | 1.5%max | 3.25min | 0.25%max | 0.4%max | 3.8%max |

| 87 | 87%min | 1.6%max | 3.20min | 0.25%max | 0.4%max | 3.8%max |

| 86 | 86%min | 1.8%max | 3.15min | 0.3%max | 0.5%max | 4%max |

| 85 | 85%min | 2.0%max | 3.10min | 0.3%max | 0.5%max | 4%max |

| 83 | 83%min | 2.0%max | 3.05min | 0.3%max | 0.5%max | 4%max |

| 80 | 80%min | 2.0%max | 3.0min | 0.3%max | 0.5%max | 4%max |

| 78 | 75-78% | 2.0%max | 2.8-2.9 | 0.3%max | 0.5%max | 4%max |

Size: 0-1mm,1-3mm,3-5mm,5-8mm,8-10mm,200mesh,325mesh or as your request.

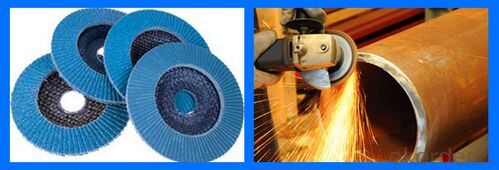

Application

mainly used in aluminium metallurgy,aiso used in abrasive ,cement ,chemical, refractory

- Q: What is the difference between metallurgical coke and chemical coke

- Quality index of cokeCoke is a solid product of high temperature carbonization, the main component is carbon, is a crack and irregular pore structure (or porous). The number of cracks has a direct impact on the strength and crushing strength of the coke, the index is generally measured in terms of crack degree (the number of cracks in the unit volume coke). The index of pore structure is mainly expressed by the porosity rate (the percentage of the total volume of coke), which affects the reactivity and strength of coke. Different uses of different coke porosity index requirements, the general requirements of metallurgical coke porosity in the 40 ~ 45%, 35 ~ 40% in coke, coke export demand in about 30%. Coke crack degree and the porosity level, and the coking coal has a direct relationship, such as coal based coke refining, crack, high porosity, low strength; with coal as the foundation of the coal refining coke crack less, low porosity and high strength. The strength of coke is usually represented by two indices of crushing strength and abrasion resistance. Coke crushing strength refers to coke can resist foreign impact force without ability along cracks or defects at the broken, represented by the M40 value; wear strength of coke coke refers to the ability to resist external friction without surface of glass forming debris or powder, said M10. The cracking degree of coke affects the M40 value of its breaking strength, and the pore structure of coke affects the M10 value. There are many methods for determination of M40 and M10 value method, commonly used in our country the German migon drum test.

- Q: What is the reasonable ratio of coal to coke

- According to the proportion of each unit type, different operation, different existing coal and different coke quality requirements are different and so on, can be said to suggest that the landlord can look at the altar of the myriads of changes, in some aspects of the coal blending, grasp some general principles, and then develop the proportion according to the actual situation.

- Q: We would like to export a batch of coke, I would like to know what information is required for a permit

- Step 1: apply for an electronic key:The electronic key is equivalent to the enterprise identity authentication, after the application is similar to online banking U shield, the cost of 350 yuan. Including the physical Key ($150) and digital certificate price ($200), where Key is a one-time fee, digital certificates for the annual cost, valid for one year.

- Q: Said the details can add points ah

- Both are expressed in terms of the crushing strength of the cold mechanical strength index of coke quality.Among them, because of the specific measurement methods are not the same, so the use of different records.

- Q: I don't understand. With coke, then the rest of the coke, they are selling it?

- If most of the solid fuel is burning coal, but coking coal, which is very strong viscosity of coal is not good, it is very interesting to use the individual plant with it, the purpose is to change the fuel characteristics.Coking coal and coke, commonly used in metallurgical industry.Coal will be heated to a process of coke, but you really want to get coke, to specialized production. Power plants do not produce coke, they only have gray coke

- Q: What is the amount of waste gas produced by a ton of coke burning

- The coking coal is heated to 1000 DEG C under the condition of isolated air (high temperature carbonization)

- Q: The sulfur content of coal and coke in general, the coking process of sulfur content of coal into the output of sulfur content of coke compared to those who are high and low?

- 80% to 90% of the sulfur in coal into coke, the other into the coke oven gas.

- Q: Braised meat burning coke, iron black layer, I do not know how to clean, please help answer

- Orange to the bottom of the potCut a few slices of orange into the pot boil, stuffy night, second days will be turned over the paste paste, it is easy to clean up.7, the old telephone card, magnetic card washing paste potProblem Description: run out of phone cards, shopping cards, discount cards, VIP cards piled up, although there are people who love this kind of thing, but most people had no interest, so, or use it to do something. When cooking is paste pot, if made of hard coke fouling cleaning shovel, cause scratches with the wooden shovel, and difficult to completely remove the coke fouling. Why not let those old cards reflect the use value?Method of operation: with the card along the edge of the pot, and gradually remove the coke scale clean. Note that when you do not need to force too hard. If the card is made of hard plastic, can also be used to scrape the dirt on the gas stove.

- Q: 8 points will be isolated from the air to enhance the heat of coal, in addition to the main coke, but also the material listed in the following table: No.

- Carbon containing ammonia, which belongs to the inorganic carbon monoxide; although contain carbon and inorganic nature but similar, belonging to the inorganic material, so the answer is: the 7;

- Q: The two day of the fire is not wang you have a good way to have any good way. Such online

- If you are at the barbecue, with the leaves, the leaves on the carbon below, with a stick carbon increase, the ignition, a side side to add some minor burns carbon. If the technology is good, probably a few minutes. If there is no dry leaves to replace paper.

Send your message to us

Sintered Bauxite,Gibbsite Bauxite ,Calcined Bauxite 88 From China !!!

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches