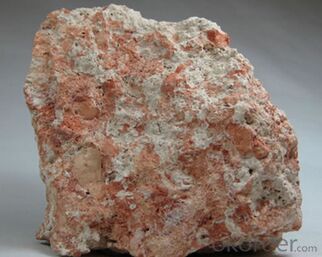

Gibbsite Bauxite,Bauxite 85 From China !!!

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Details: | In 25KG bags;1MT/1.25MT/1.35MT bags or as your requirements. |

| Delivery Detail: | 15-30 days after contract |

Product Description

| Items | Al2O3 | Fe2O3 | B.D. | K2O+Na2O | CaO+Mgo | TiO2 |

| 88 | 88%min | 1.5%max | 3.25min | 0.25%max | 0.4%max | 3.8%max |

| 87 | 87%min | 1.6%max | 3.20min | 0.25%max | 0.4%max | 3.8%max |

| 86 | 86%min | 1.8%max | 3.15min | 0.3%max | 0.5%max | 4%max |

| 85 | 85%min | 2.0%max | 3.10min | 0.3%max | 0.5%max | 4%max |

| 83 | 83%min | 2.0%max | 3.05min | 0.3%max | 0.5%max | 4%max |

| 80 | 80%min | 2.0%max | 3.0min | 0.3%max | 0.5%max | 4%max |

| 78 | 75-78% | 2.0%max | 2.8-2.9 | 0.3%max | 0.5%max | 4%max |

Size: 0-1mm,1-3mm,3-5mm,5-8mm,8-10mm,200mesh,325mesh or as your request.

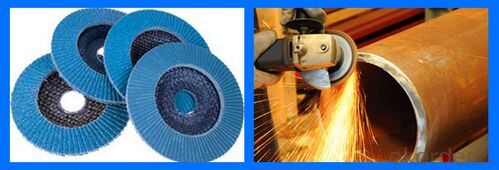

Application

mainly used in aluminium metallurgy,aiso used in abrasive ,cement ,chemical, refractory

- Q: What is cokeWhat applications are, what is the fire of Malachite copper

- Coke is used for heating, and coke is also used as a reducing agent to process the iron ore, the oxide ore, the malachite is the copper oxide

- Q: What are the indicators of first grade coke and the two grade coke?

- No greater than 12 is not greater than 0.6 not less than 80 not greater than 8 not greater than 1.9

- Q: Used in a restaurant?Dry or dry carbon carbon, coke or coke, and I do not know which word is a word of this sound. The use of coke for iron making. They are more than 1000 yuan price.The main problem is: dry carbon is coke?Toxic smoke, then the chimney can not do? Can I use the blower?

- Dry carbon is not coke, but the combustion will produce a lot of harmful substances, it is recommended to install a more advanced cleaning device. Thank you

- Q: Coking coal, coke, coal, steam coal what is the difference?

- Coke is used for blast furnace ironmaking and iron ore in the steel furnace to play the role of the heating skeleton to support reducing agent

- Q: I see that there are metallurgical coke and coke on the Internet, what is the difference between them (I hope to be able to say in detail) and a level of two points, how is this going on?.. Where is the quality of coke in China? Hunan good coke plant which? Although the problem is a little bit more, I hope that insiders can give some useful information. Extremely grateful.

- I see that there are metallurgical coke and coke on the Internet, what is the difference between them (I hope to be able to say in detail) and a level of two points, how is this going on?.. Where is the quality of coke in China? Hunan good coke plant which? Although the problem is a little bit more, I hope that insiders can give some useful information. Extremely grateful.

- Q: I now do a good job in the coke network editor, I would like to know more about coke

- (2) reducing agent.The reduction of ore in blast furnace is accomplished by indirect reduction and direct reduction. The indirect reduction is about 400 degrees centigrade. The indirect reduction is rising gas CO reduction in ore, iron oxide from high iron gradually reduced low iron until the metal iron, while producing CO2:

- Q: Do not understand why some of the indicators of coke is the cause of the full analysis of phosphorus or foundry use of this time?It is best to use the foundry requirements? Thank you

- Phosphorus increased the brittleness of cast iron, the use of metal damage. Therefore, the requirements of the foundry phosphorus is the lower the better. Because of the large cupola furnace in the furnace is acidic, can not effectively dephosphorization, so the foundry coke in the phosphorus requirements as low as possible, and require the supplier to provide a quality guarantee form.

- Q: Purpose of using coke in iron making raw materials

- It can capture the oxygen atoms in iron oxide or magnetic iron oxide to form carbon dioxide. The reaction equation is as follows:3C+2 (Fe2O3) = ==3 (CO2) +2Fe at high temperature2C+ (Fe3O4) = ==2 (CO2) +3Fe at high temperature

- Q: I work in the coking plant, so there are conditions to get coke and is burning, I would like to use coke barbecue line? Just like charcoal Mutton Cubes Roasted on a Skewer, OK? Understand the answer

- I work in the coking plant, so there are conditions to get coke and is burning, I would like to use coke barbecue line? Just like charcoal Mutton Cubes Roasted on a Skewer, OK? Understand the answer

- Q: How much coke is needed for a ton of iron

- 1 tons of iron: iron ore + + coke 340kg + pulverized coal injection 130kg,The process of extracting iron from iron containing minerals, mainly iron oxides, is mainly composed of blast furnace, direct reduction, smelting reduction and plasma method. From the perspective of ironmaking is metallurgy, iron rust, inverse behavior gradually mineralized, simple, pure iron reduction from iron compounds. Pure iron is not common in actual production. More iron carbon alloy.

Send your message to us

Gibbsite Bauxite,Bauxite 85 From China !!!

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches