Stylus Packaging Tape Dispenser - Single Waterproof Sided Acrylic Masking Tape

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6500 m

- Supply Capability:

- 60000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Company information

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM GroupCorporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.Our goal is to transform CNBM International into the global leading brand in building materials industry within 3 to 5 years through innovation and reform, by strengthening the overall management of supply chain, developing and cultivating both domestic and overseas market, improving the procedure and information system, enhancing the ability to organize resources and to provide value-added services under a professional team and a learning organization.

2.Product details

Item | Results |

Adhesive type | Acrylic Glue |

Backing material | Crepe paper |

Thickness(um) | 135-140 |

Initial Adhesive (Ball test)( #) | ≥16 |

The 180 ° peel strength(N/25mm) | ≥3.3 |

Holding power (to stainless steel) ( Hrs) | ≥12 |

Tensile Strength(N/25mm) | ≥71 |

Elongation at break(%) | ≥12% |

Temperature resistance | 100℃*120min |

UV resistance(days) | >18 |

Shelf life(Years) | 2 |

3.Packaging & Delivery

In shrink film and carton packed.

24pcs/ctn, 36pcs/ctn, 72pcs/ctn

Other packages also available as requirement.

Delivery Detail:

2 weeks when the order confirmed and deposit received

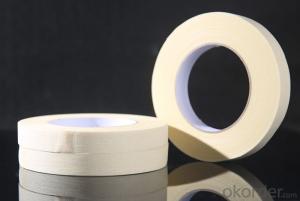

4.Product show

5.Our services

1.OEM Service

Your own design is appreciated; we can make the approval sample according to your golden sample.

2. After-sale Service

a) EXW, FOB, C&F are also available for us.

b) If the products need certificate, we can also provide.

- Q: Is packaging tape easy to write on?

- Yes, packaging tape is generally easy to write on. It provides a smooth surface for writing and most pens or markers adhere well to it, allowing you to write clearly and legibly on the tape.

- Q: Can packaging tape be recycled?

- Yes, packaging tape can be recycled. However, it is important to remove the tape from the packaging material before recycling.

- Q: Is packaging tape safe for use on photos or artwork?

- Although packaging tape can be used on photos or artwork, it is not the optimal choice. Its primary purpose is to secure boxes and packages, and it may not offer long-term protection or be archival quality. Using packaging tape on photos or artwork has the potential to harm the surface or leave residue upon removal. Additionally, it may gradually yellow or discolor over time, thereby affecting the visual appeal of the artwork or photo. To preserve the longevity and integrity of your photos or artwork, it is recommended to employ acid-free archival tape specifically designed for this purpose. Archival tape is crafted with materials that are safe for delicate surfaces and can be effortlessly removed without causing any damage. In conclusion, while packaging tape can serve as a temporary solution, it is advisable to utilize archival tape to ensure the utmost protection for your valuable photos or artwork.

- Q: Are there different colors of packaging tape?

- Yes, there are different colors of packaging tape available.

- Q: Can packaging tape be used for sealing chemical or hazardous material containers?

- Sealing chemical or hazardous material containers with packaging tape is not advised due to its lack of necessary properties for effective containment and prevention of leakage. These substances often necessitate specialized containers and sealing methods to ensure safety and compliance with regulations. These specialized containers are engineered to withstand the corrosive or reactive nature of the substances they hold, with seals designed to provide a secure and leak-proof closure. In contrast, using packaging tape can be risky as it may result in leakage, contamination, and exposure to harmful substances. It cannot reliably serve as a barrier against leaks or spills, potentially leading to accidents, injuries, or environmental harm. To properly seal chemical or hazardous material containers, it is recommended to use specific sealing materials that are specifically designed for this purpose. This may involve utilizing specialized caps, gaskets, or seals that are compatible with the specific substance being contained. Moreover, it is crucial to adhere to the guidelines and regulations provided by relevant authorities to ensure the safe handling, storage, and transportation of these materials.

- Q: Can packaging tape be used for sealing metal boxes?

- Indeed, metal boxes can be sealed using packaging tape. Specifically engineered to create a secure and long-lasting seal on different surfaces, such as metal, packaging tape possesses a powerful adhesive that effectively adheres to metal, guaranteeing that the box stays sealed throughout storage or transportation. Nevertheless, it is crucial to select a packaging tape appropriate for demanding tasks, capable of enduring the weight and pressure that the metal box may experience. Furthermore, it is advised to cleanse the metal surface prior to applying the tape to ensure optimal adhesion.

- Q: Can packaging tape be used for sealing plastic or poly bags?

- Certainly! Packaging tape is capable of sealing plastic or poly bags. Its design is focused on creating a strong and secure seal on different surfaces, such as plastic and poly bags. By utilizing an adhesive backing, the tape effectively sticks to the plastic material, guaranteeing a tightly sealed bag. Nevertheless, it is crucial to consider that there are various types of packaging tape accessible. To achieve optimal performance and a durable seal, it is advisable to select a tape that is explicitly designed for sealing plastic or poly bags.

- Q: Can packaging tape be used for sealing packages with medical or pharmaceutical products?

- Yes, packaging tape can be used for sealing packages containing medical or pharmaceutical products. However, it is important to ensure that the packaging tape used is of high quality and specifically designed for such sensitive products to maintain their integrity and prevent any contamination.

- Q: How do I prevent packaging tape from becoming too loose?

- Here are some helpful suggestions for preventing packaging tape from becoming loose: 1. Opt for high-quality packaging tape: Invest in packaging tape that boasts a strong adhesive. Inferior quality tapes tend to lose their stickiness quickly, resulting in loose packaging. 2. Ensure cleanliness and dryness of surfaces: Prior to applying the tape, make sure that the surfaces are clean and dry. Dust, moisture, or oil can weaken the adhesive and cause the tape to loosen. 3. Apply firm pressure: When sealing a package, exert firm pressure while affixing the tape onto the surface. Be sure to run your hand or a flat object along the length of the tape to ensure proper adhesion. 4. Utilize overlapping tape: Instead of using only a single strip of tape, overlap it by a few inches. This overlapping technique provides added strength and diminishes the likelihood of the tape becoming loose. 5. Avoid extreme temperature fluctuations: Extreme temperature changes can adversely affect the adhesive properties of packaging tape. Refrain from storing packages in areas with high humidity or extreme temperature variations, as this can cause the tape to loosen. 6. Strengthen with extra tape: If you are sealing a heavy or bulky package, contemplate reinforcing it with additional tape. Apply extra strips of tape across the sides or diagonally to provide supplementary support and minimize the risk of the tape coming loose. 7. Properly store packages: When storing packages, ensure they are stacked correctly and not subjected to excessive pressure or weight. Inadequate storage conditions can cause the tape to loosen over time. By adhering to these recommendations, you can effectively prevent packaging tape from becoming too loose, thereby guaranteeing that your packages remain securely sealed during transit or storage.

- Q: What are the different adhesive options available for packaging tape?

- Packaging tape offers several adhesive options, each with its own distinct qualities and suitability for different uses. 1. Acrylic adhesive is commonly used in packaging tape due to its versatility. It adheres well to various surfaces and has excellent clarity, making it perfect for transparent or light-colored packaging. Additionally, acrylic adhesive forms a long-lasting bond and performs reliably in both hot and cold temperatures. 2. Hot melt adhesive is formulated for instant and strong bonding. It has a high initial tack and excellent holding power, making it ideal for heavy-duty applications or sealing boxes with rough or recycled surfaces. Moreover, hot melt adhesive withstands extreme temperatures and resists aging. 3. Natural rubber adhesive excels in adhesion to different surfaces, including recycled materials. Its high tackiness ensures a secure bond, even on challenging surfaces. Furthermore, natural rubber adhesive is resistant to UV light and aging, making it suitable for long-term storage or outdoor use. 4. Synthetic rubber adhesive, like natural rubber adhesive, provides strong adhesion to a wide range of surfaces. It offers good resistance to aging, moisture, and temperature changes, making it suitable for various packaging applications. 5. Solvent-based adhesive stands out for its high initial tack and excellent bonding strength. It quickly forms a bond, particularly on challenging surfaces like corrugated cardboard or recycled materials. However, it may emit strong odors and require extra safety precautions during use. When selecting an adhesive for packaging tape, it is crucial to consider factors such as the packaging material, surface conditions, environmental factors, and specific application requirements. Seeking guidance from adhesive manufacturers or suppliers can aid in determining the most suitable adhesive for your packaging needs.

Send your message to us

Stylus Packaging Tape Dispenser - Single Waterproof Sided Acrylic Masking Tape

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6500 m

- Supply Capability:

- 60000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches