Silicone Coated Raw Material Glass fiber Chopped Strands Matting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 44 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduce

E-glass chopped strand mat &fiber glass Matis an non-woven E- or C-glass fiberglass fabric manufactured by spreading continuous filament rovings of 50mm in length randomly and uniformly in combination with polyester binder in power form (or other binder in emulsion form).

Application

Chopped Strand Mat is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the application by hand lay-up FRP moldings, such as, various sheets and panels, boat hulls, boat tubs, cooling towers, corrosion resistant, vehicles, etc.

Specification

Glass type: E-glass and C-glass Chopped Strand Mat.

Bond type: Powder or Emulsion.

Density: 80g/m2-900g/m2.

Normal types: 180g/m2. 225g/m2. 300g/m2 450g/m2. 600m2.

Bond Content: 100g/m2 (10%-15%). 300g/m2.450g/m2.600g/m2 (4%-6%)

Roll Width: 200mm-2600mm.

Normal types: 750mm.1040mm.1250mm.1270mm.1450mm.

Roll weight/: 28kgs-55kgs.

Normal types :28kgs.30kgs.35kgs

Package

Product is manufacture in form of a roll warp on a paper tube then after packed in a plastic bag and placed with in a cardboard .Carton. Rolls can be loaded in a container directly or on pallets.

Quantity(Fiberglass mat)

20’GP container: about 10000kgs

40’HC container :about 23100kgs

Technical Date

Property | Glass Type | Weight(g/m2) | Width | Roll weight | Moisture Content % | Combustible Content% | Breakage Strength N |

Test Method | GB/T 1549 | ISO3374:2000 | ISO3374 | GB/T 17470-1998 | ISO3344:1997 | ISO1887:1995 | ISO3342 |

EMC80 | E/C-GLASS | 80±16 | ±5 | 6~95 | <0.2< span=""> | 13.6±0.35 | ≥200 |

EMC100 | E/C-GLASS | 100±20 | ±5 | 6~95 | <0.2< span=""> | 9.5±0.35 | ≥170 |

EMC150 | E/C-GLASS | 150±30 | ±5 | 6~95 | <0.2< span=""> | 8.0±0.35 | ≥40 |

EMC225 | E/C-GLASS | 225±45 | ±5 | 6~95 | <0.2< span=""> | 5.0±0.35 | ≥60 |

EMC300 | E/C-GLASS | 300±60 | ±5 | 6~95 | <0.2< span=""> | 4.0±0.35 | ≥90 |

EMC450 | E/C-GLASS | 450±90 | ±5 | 6~95 | <0.2< span=""> | 3.8±0.35 | ≥120 |

EMC600 | E/C-GLASS | 600±120 | ±5 | 6~95 | <0.2< span=""> | 3.6±0.35 | ≥150 |

EMC900 | E/C-GLASS | 900±180 | ±5 | 6~95 | <0.2< span=""> | 3.4±0.35 | ≥180 |

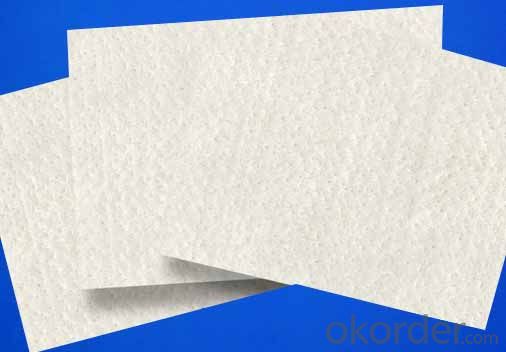

Picture

Package

workshop

FAQ

1.Q: What specification do you have for E glass Fiberglass chopped strand mat ?

A: Now our normal specification of fiberglass mat have 45/50/55/60/90/100gsm, can be customized.

2.Q:How about the width?

A:The normal width is 1000mm, can be customized.

3.Q:How about the sample delivery?

A.Small sample is free of charge, sample ready time 3-5days.

4.Q:How about the delivery time?

A:It is depend on the order quantity, three 20'ft container around 20days.

- Q: Waterproof materials related to the raw materials which ah

- ④ metal waterproof material. Thin steel plate, galvanized steel plate, pressure plate, coated steel plate can be directly used as roof panels, for waterproof. A sheet of metal used in a basement or underground structure. Thin copper plate, thin aluminum plate, stainless steel plate can be made of structural deformation of the sealing water zone. Metal waterproof layer of the connection to be welded, and brushing rust protection paint.

Send your message to us

Silicone Coated Raw Material Glass fiber Chopped Strands Matting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 44 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords