Sheet Metal Fabrication with The Best Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

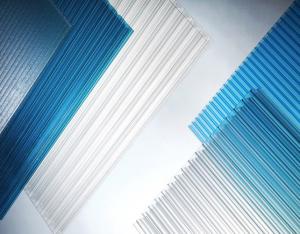

Size of products

Thickness(mm) | 8mm to 30mm |

Length(mm) | No limited |

Width(mm) | Within 2100mm |

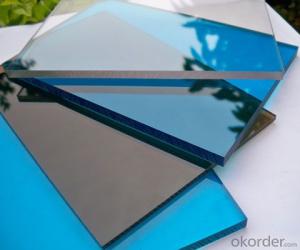

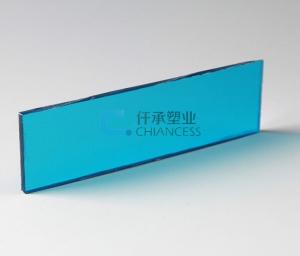

Color | Clear Opal Green Blue Bronze lake Blue and so on |

Production line | Two line for PC hollow sheet and One line for PC solid sheet |

Raw materials | The raw materials of pc come from German named Bayer |

Characteristics of Polycarbonate solid sheet

1. Light Transmission:The light transmission reaches 12% to 82%, depending upon color and thickness. It will not get yellow, atomization, and poor transmittance. Light transmission loss only 6% after ten years.

2. Impact Resistance: Its impact strength is 250-300 times of ordinary glass, 30 times of acrylic plate with the equivalent thickness, and 2-20 times of tempered glass. It would not crack after falling down two meters with a 3KGhammer hit, known as "unbroken glass" and "ring of steel".

3. Light Weight: Only half weight of the glass, saving the costs of transportation, unloading, installation, and supporting frame

4. Fire Retardancy: Fire Retardancy grade B1 decided by the national GB8624-97 test, without fire drop nor poisonous gas. The flaming point is 580 ° C. It‘s features self-extinguishing away from fire, no toxic gases made when burned and it do not contribute to the spread of fire.

5. Weather Ability: It has good weather ability, can maintain excellent propertities in a wide temperature range from -40 ° C~120 ° C, short-term bearing temperature allow-100 ℃ ~ + 135 ℃. Low temperature brittleness of -100 ℃, high temperature softening temperature of 146 ℃.

6. Good workability: It can be hand-cut, do need to warm at room temperature can be cold. Light weight, easy handling, bored. When truncated install, easy to break, easy construction process well.

7. Sound insulation: With its good sound insulation, it is the material of best choice for highway noise barriers in the world. Noise characteristics of the material are determined by the hardness, weight and physical structure.

8. Pollution-free, environmentally friendly, non-toxic, tasteless, no radiation, no toxic substances during the production and use, is recyclable and modern new green building materials.

on door, curtain wall

- Q: How to correctly identify the quality of pc sunshine board and pc durability plate method

- Look at the product surface. Protective film paste flat, no shedding. Indicating that manufacturers of product production, sales attention. Of course, some bag companies, small companies pay attention to packaging, because this customer is like moon cakes, in the use, the best choice for the strength of the old company

- Q: Who can tell me, plastic hollow board and PC sun board in the end what is the difference?

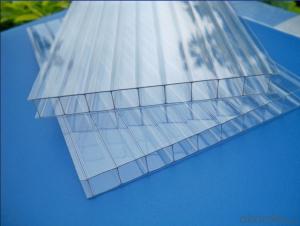

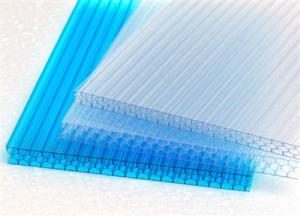

- Compared with the traditional ordinary film, it has the following advantages: ?1. Transparency reached 81%, has to keep up with ordinary film, can be planted on the promotion of vegetables. 2. Double-layer hollow structure, greatly weakened the strong exchange of hot and cold air, the greenhouse was basically in the state without dripping, greenhouse less mist, indoor relative humidity at a long time below 80%, greatly reducing the disease of the planted. 3. Double-layer hollow structure, good temperature effect, the thermal energy storage capacity of solar energy is strong, slow greenhouse temperature at night, are high-temperature covering materials. There are documented proofs that are 2 ° C higher than the temperature of the traditional shed. 4. Double hollow structure, the middle of the ribs, wind, snow pressure ability, not easy to tear. 5. Long life, do not have to replace each year, save hours, flowers, aquatic products, livestock and other greenhouse, has been used for more than 10 years of records. 6, due to the many advantages of the above, and after more than ten years of natural weather resistance test, so we believe that double insulation film (PE sun board) can be China's agriculture, animal husbandry (pig, chicken, raise Ducks, cattle, sheep, special breeding, etc.) aquaculture, flower planting, forestry nursery, etc., the construction of many low-cost, low humidity, long life, high-quality high-quality solar greenhouse.

- Q: What is the difference between PC stamina and PC sunboard?

- In addition, the use of sun panels and endurance boards are the same in many ways, but there are also differences, such as sun panels are generally used in the stadium lighting roof, greenhouse lighting ceiling, warehouse lighting roof and so on. Stamina board is used to make shields, outdoor light boxes, advertising signs, etc. are more common. So customers in the choice of PC sun panels, PC Nai Liban or need to be based on their actual use and needs to choose.

- Q: What is the difference between a hollow board and a sunboard?

- Sunshine board is one of the lighting board, most of the lighting board is made of FRP and the sun is made of PC (polycarbonate) made, a little PC board warranty period is 10 years and 15 years, The better FRP lighting board warranty period of 20 years, 25 years. Performance comparison, although the thermal conductivity of the lighting board than the sun board is low, but the lighting board is usually a single layer, thermal conductivity than the sun plate. That is the summer sun exposure, then, under the lighting board room temperature to be higher. Light transmittance, carrying capacity under normal circumstances 2 can meet.

- Q: How much of the installation of the sun board installation of a square meter

- The sun panels are mainly made of PC / PET / PMMA / PP. English is sunlight, referred to as hollow board, pc sun panels to polycarbonate as the main raw material manufacturing. Sunshine board in the mid-80s into the building materials quickly.

- Q: Can the stencils be made in the bathroom?

- Of course you can, if the choice of PC particle board to do partition, can add the bathroom hazy beauty, really have not seen with the endurance board to do, not practical and ugly

- Q: Project sun board price how much

- Thickness 16mm - 40mm, the price is generally 80 yuan - 260 yuan / ㎡, this interval thickness of the PC sun panels generally use less, but also a variety of shapes. Global PC sunshine board prices are different.

- Q: What is the difference between the PC and the PC board?

- Pc stamina board and PC particle board belong to the solid plate, the difference is that the endurance plate is very smooth, and the particles that the diamond is like a rugged.

- Q: Company pc sunshine board how to solve the problem

- Two layers of waterproof treatment: sun board endurance board joints with a wide aluminum alloy bar, in the pressure below the bonding of special waterproof tape, and then use a good quality neutral sealant on both sides of the pressure to play the thickness of 5 mm width 5 -8 mm silicone.

- Q: Sunshine board price per square meter, PC sun board how much money a square meter

- Thickness of 6mm - 16mm, the general price of 25 yuan -100 yuan / ㎡, the thickness of the sunshine plate is more commonly used, the structure is divided into two layers, three, four, X type, meter type, honeycomb type.

Send your message to us

Sheet Metal Fabrication with The Best Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords