Shear Studs Connectors Through Decking Ferrule for Construction

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Detail

Basic Info

Material: Carbon Steel,Alloy Steel,Stainless Steel

Diameter: 10mm-25mm

Grade: 4.8...etc

Length: 40mm-300mm

Certificate: CE,ISO 9001:2008,Uktc,SGS

Set: Wtih Ceramic Ferrule

Surface Treatment: Plain,Phosphate,Nature

Sample: Free

Delivery Detail: 7-30 Days or According to Your Order

MOQ: 3000PCS

Export Markets: North America, South America, Southeast Asia, Africa, Mid East, Eastern Asia

Additional Info

Packing: Carton and Wooden Pallet

Standard: ISO 13918, AWS D1.1, NELSON, BS

Origin: Xiaoshan, Hangzhou, Zhejiang, China

HS Code: 731829

Production Capacity: 1000000PCS/Month

Product Description

Shear Connector Studs are designed to tie the concrete to the steel beams and to resist shear loadings

between the concrete slab and steel beam in composite construction.

Shear connectors on the top flanges of the steel girders provide the means to achieve composite action between the slab and the girders, thus increasing both stiffness and strength.

Fasteners used to attach a structure or object to concrete. They can be used with many base materials including concrete, brick and block. Shear connectors are welded to surfaces in order to resist shear between elements of a composite beam.

Shear studs are used in stud welding to secure steel framed buildings to create a shear connection between

the steel and the concrete. We supply and fix all available sizes of welded shear studs for through deck

and straight to steel welding.

Burn off value shown are for welding to bare steel.

Length: Length is before weld. Stud when welded to base metal will be approximately 5mm shorter after weld and when welded through deck 10mm shorter after weld. Lengths for shear connect studs are generally set by governing specification.

Shear Stud; Shear Connector with Arc Welding; Weld Stud for Steel Decking with

ceramic ferrules.

Shear Connector Studs are designed to tie the concrete to the steel beams and to resist shear loadings

between the concrete slab and steel beam in composite construction.

Shear studs are used in stud welding to secure steel framed buildings to create a shear connection between

the steel and the concrete. We supply and fix all available sizes of welded shear studs for through deck

and straight to steel welding.

Burn off value shown are for welding to bare steel.

The ISO 13918 SINOARSTM shear studs (shear connectors) use the ISO13918 standard Type UF and PF ceramic

ferrules,other special type available upon request.

When inquire prices and ordering, please specify name, standard, type, specification (LBW), quantity, special requirements

(if have), etc., eg.

Shear Stud, ISO 13918, Type SD, 22x150 (LBW), 60,000 Pieces.

Quality Control &Test Assurance Lab

We carry out strict quality control, from high rates inspection of raw material &incoming products to ensure the step quality.

The test for every procesure of producing throughly, we inspect occasionally during the producing process. As we are

dedicated to provide the quality products to our customers. By doing these, we had constantly assured our products 100%

satisfication and get our customer approval for our service and quality.

Shear connector/shear stud introduction:

Description | Shear connectors, shear studs, welding studs |

Materials | Carbon steel or stainless steel |

Available specs | GB/T 10433,ASTM A108,ASW D1.1,EN ISO13918,AS/NZS1554,JIS B1198 |

Dia | M12-M25(1/2”-1”) |

Length | 50-300MM(2”-11-3/4”) |

Head mark | HYZ or customized |

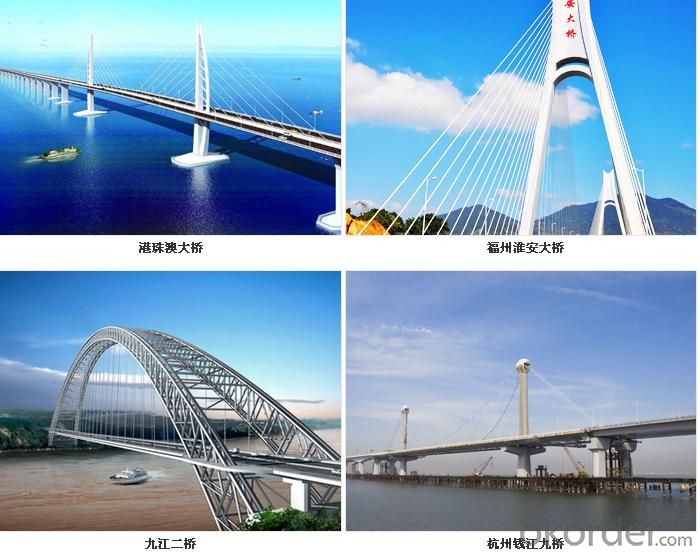

Used | Steel structures such as bridge construction, airport, railway, multi-floor& high-rise steel structure building,ect |

Prouduct Show:

FAQ

Acceptable payment term and way?

T/T,L/C, T/T + L/C,

Acceptable price term?

FOB CNF CIF DDU CPT

Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value

Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

What is the validity of your quotation?

Normally 7 days.

What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: Who include who btween them?

- Fasteners are said from the point of view of the action, which contains both standard parts (GB ANSI ASME DIN EU JIS, etc.) and non-standard parts (according to the drawings) is not entirely a concept

- Q: High-strength screw standard parts of the quality of what data

- The other can be based on the corresponding use of the environment, to decide whether to accept or not accepted.

- Q: Fasteners often say that the nature of galvanized oxidation is what it means

- True color means that the surface of the fastener is not treated. Galvanized refers to non-zinc easily oxidized metal fastener surface coated with a layer of zinc, the role is to prevent its rust. Oxidation refers to the surface of the metal fastener through a chemical reaction to produce a layer of rust-proof film, the main role is rust, the other can also beautify the appearance.

- Q: A194 GR3 is what style fasteners

- ASTM A194 is high pressure and, or high temperature conditions with the bolt to match the carbon steel and alloy steel nuts, as GR3 I did not see such a description in the standard

- Q: Who is the information on fasteners ah?

- Automotive and various vehicle fasteners, building decoration fasteners, furniture fasteners, home appliances fasteners, electronic fasteners, general standard fasteners.

- Q: For the commonly used standard parts, for some of the quality of good or bad, how to distinguish,

- If the hexagonal hexagonal, with your fixed wrench or torque wrench directly try the size of the accuracy, tight to see a few times to see wear resistance.

- Q: What is the name of the screw (fastener)?

- Screw, it was also called "screw" [screw], "screw" (screw). In fact, the screw is known, and the screws, screw rods are different from each other. Screws are generally called wood screws; is the tip of the kind of tip, pitch larger, generally used to tighten wood parts, plastic parts. Screw is a screw (mechanical screw), is the front of the kind of flat head, pitch is small, uniform, generally used to fasten the metal, machine parts.

- Q: Does the fastener include screws?

- Fastener fasteners are also known as standard parts on the market and are a generic term for a class of mechanical parts that are used when two or more parts (or components) are tightly connected as a unit. It is characterized by a wide variety of specifications, performance purposes vary, and standardization, serialization, the degree of generalization is very high. Fasteners are the most widely used mechanical base pieces and are in great demand.

- Q: What are all the fasteners?

- Of course, there are many categories of fasteners, in short, there are many, many of the fasteners.

- Q: Will the stainless steel fastening standard parts of the national standard code and name?

- Because the fastener is a standard part, so the size of stainless steel fasteners and ordinary fastener size is the same, other standard GB / T 5267.4-2009 fastener surface treatment corrosion-resistant stainless steel passivation treatment

Send your message to us

Shear Studs Connectors Through Decking Ferrule for Construction

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords