Shear Stud Connectors for Steel Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:M19*115

Material:Carbon Steel

Surface Finishing:Plain&Black

Grade:A

Certification:ISO, CE, SGS

Customized:Customized

Product Name:Nelson Shear Stud Connector

Type:Nelson Shear Stud

Raw Material:Carbon Steel Ml15al (Swrch15A)

Support Standard:ISO 13918 ; GB/T10433; Aws D1.1

Surface Treatment:Plain &Black

Diameter:M10 M13 M16 M19 M22 M25

Length:40-300mm

Tensile Strength:>= 450n/Mm2

Yield Point:>= 350n/Mm2

Elongation Percentage:>= 15%

Export Markets:Global

Additional Info.

Packing:Carton &Barrel &Pallet for Welding Shear Stud

Standard:ISO 13918; GB/T10433; AWS D1.1

Origin:Tianjin

HS Code:7318290000

Production Capacity:2000 Ton/Tons Per Month 100X20′′gp Shear Stud

Product Description

Shear studs are used in stud welding to secure steel framed buildings to create a shear connection between the steel and the concrete. We supply and fix all available sizes of welded shear studs for through deck and straight to steel welding.

All our products meet the current standards and specifications

The ISO 13918 SINOARSTM shear studs (shear connectors) use the ISO13918 standard Type UF and PF ceramic

ferrules,other special type available upon request.

When inquire prices and ordering, please specify name, standard, type, specification (LBW), quantity, special requirements(if have), etc., eg.

Shear Stud, ISO 13918, Type SD, 22x150 (LBW), 60,000 Pieces.

ISO 13918 Nelson Welding Shear Stud Connector

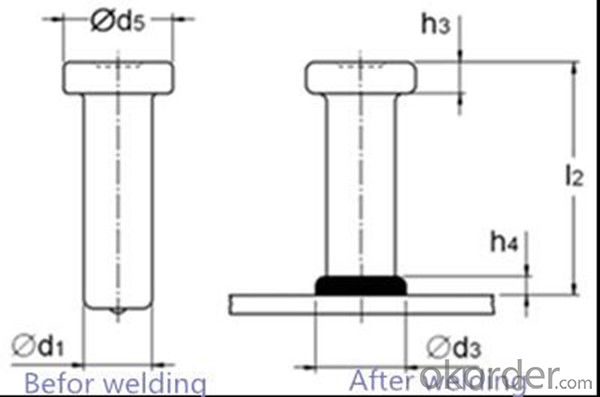

Production Discription:

| ||||||

d1-0.4 | 10 | 13 | 16 | 19 | 22 | 25 |

d5±0.3 | 19 | 25 | 32 | 32 | 35 | 41 |

d3±0.3 | 13 | 17 | 21 | 23 | 29 | 31 |

h3±0.5 | 7 | 8 | 8 | 10 | 10 | 12 |

h4 | 2.5 | 3 | 4.5 | 6 | 6 | 7 |

L1±1.5 | 40-105 | 40-160 | 40-200 | 40-250 | 60-250 | 60-250 |

Burn off | 3 | 3 | 4 | 5 | 5 | 6 |

Ferrule | UF10 | UF13 | UF16 | UF19 | UF22 | UF25 |

1.Burn off value shown are for welding to bare steel

2.There are two kinds of ceramic ferrule, one is through deck type which has 8 teeth,

the other one is common type which has 18 teeth.

The price is same for these two types.

3.The UFB type ceramic ferrule are for through deck welding , with 8 teeth !

| ||||

1/2-0.01 | 5/8-0.01 | 3/4-0.015 | 7/8-0.015 | |

d5±1/64 | 1 | 1-1/4 | 1-1/4 | 1-3/8 |

h3 | 9/32 | 9/32 | 3/8 | 3.8 |

L1±1/16 | 2-5.9 | 2-7.874 | 2-9.84 | 3.15-9.84 |

Burn off | 0.125 | 0.187 | 0.187 | 0.187 |

Ferrule | UF13 | UF16 | UF19 | UF22 |

| ||||||

Material | C | Si | Mn | P | S | Al |

ML15AL | 0.13-0.18 | ≤0.10 | 0.30-0.60 | ≤0.035 | ≤0.035 | ≥0.020 |

SWRCH18A | 0.15-0.20 | ≤0.10 | 0.60-0.90 | ≤0.030 | ≤0.035 | ≥0.020 |

| Mechanical Properties | ||||

| Country | Tensile strength BN/mm2 | Yield point BS/mm2 | Elongation percentage δ% | Contraction percentage Ψ% |

| BS EN ISO13918:2008 | ≥450 | ≥350 | ≥15 | |

| USA ANSI/AWS D1.1 | ≥415 | ≥345 | δ4≥20 | ≥50 |

| CHINA GB/T10433 | ≥400 | ≥320 | δ5≥14 | |

By advanced production technology and strictly inspection system, our shear stud

connectors meet the standard of EN ISO 13918 or AWS D1.1,

both dimensions and mechanical properties are according to the above standards:

Tensile strength min. 450Mpa, Yield strength min. 350Mpa, Elongation min 15%, etc.

FAQ:

Acceptable payment term and way?

T/T,L/C, T/T + L/C,

Acceptable price term?

FOB CNF CIF DDU CPT

Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value

Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

What is the validity of your quotation?

Normally 7 days.

What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: Who include who btween them?

- Fasteners are said from the point of view of the action, which contains both standard parts (GB ANSI ASME DIN EU JIS, etc.) and non-standard parts (according to the drawings) is not entirely a concept

- Q: What is the fastener and others?

- Definition: Components used to join and fasten components.

- Q: What are some of the common fastener products?

- The washer is a flat, rounded fastener that is typically mounted between bolts, screws, or between the support surface of the nut and the surface of the connecting part to increase the contact area of the connected part and reduce the pressure in a certain area , To ensure that the connection parts will not be damaged; there is a flexible washer, but also to prevent the nut loose situation.

- Q: High-strength screw standard parts of the quality of what data

- High strength bolts are used for connecting bridges, rails, high pressure and ultrahigh pressure equipment.

- Q: For the commonly used standard parts, for some of the quality of good or bad, how to distinguish,

- Thread: Do not have chaos, roughness standards, internal and external thread test sets of each other about. search for

- Q: What is the name of the screw (fastener)?

- By specifications: M3. M4. M5. M6. M8. M10. M12 By head type: a. Flat head b. Small head (countersunk head)By the shape: a. Cylindrical light body b. Hexagonal c. Semi-hexagonal d. Cylindrical column posture

- Q: Are there categories of fasteners classified by material?

- Mainly carbon steel, alloy steel, stainless steel, other materials category

- Q: What are all the fasteners?

- Go to the professional fastener website to learn it! Really too much, too hard to classify. I hope I can help you.

- Q: Will the stainless steel fastening standard parts of the national standard code and name?

- Because the fastener is a standard part, so the size of stainless steel fasteners and ordinary fastener size is the same, other standard GB / T 5267.4-2009 fastener surface treatment corrosion-resistant stainless steel passivation treatment

- Q: Our company to purchase a number of fasteners to see when the CAD drawings in the technical requirements I do not know the specific to write those content

- You mark the standard number and grade on the line, but the general standard is not required to issue a drawing. Quality inspection in accordance with the standard check can be.

Send your message to us

Shear Stud Connectors for Steel Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords