Semi-transparent Static Film to Protect Electronical Parts

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Semi-transparent Static Film to Protect Electronical Parts

Metal in static shielding film made our of VMPET/PE films for packaging ESD sensitive devices.It is uesed for making ESD static shielding bags ,Thoes films are available with or without printing

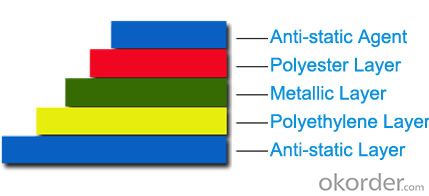

Film construction:

Anti-static Static Shielding Film echnical Data

| Electrical Properties | Typical Values | Test Method |

| Surface Resistance | ANSI/ESD STM 11.11 | |

| Interior | <10E11ohms | |

| Exterio | <10E11 ohms | |

| Metal | <100 ohms | |

| Static Shielding | <15 nJ | ANSI/ ESD STM11.31 |

| Static Decay | <0.03 seconds | EIA 541 |

| Charge Generation | < 100 volts | ** 15kV and 12% RH |

| Physical Properties | ||

| Material Thickness | 3.6mil+/-10% | ** |

| Puncture Resistance | ≥10.0lbs | MIL-PRF-81705D |

| Tensile Strength | > 4500 psi MD/TD | ASTM D882 |

| Seam Strength | No separation | MIL-PRF-81705D |

| Optical Density | Opaque(Sliver) | ASTM D-882 |

| Heating sealing Conditions | 375°F 0.5sec.60 PSI | ** |

| MVTR | < 0.02grams/100sq. in/day | ASTM F-1249 |

| Appearance | No tears,holes,sctratches,etc. | |

| Chemical Properties | .Compliant to ROHS,REACH, | |

| Halogen free ETC requirement | ||

| Amines/Amides | Not detected | FTIR |

Antistatic Static Shield Film Roll Film specifications:

Width:450-1300mm

Thickness:0.07-0.17mm

Printing: Standard with ESD requirements,approx 50X50mm

Yellow. Date code(YYMM).

About us :

Btree is China's top 5 supplier of Static Shielding Bags and Moisture Barrier Protection. We offer a full range of

ESD Packaging solutions. Speak to our friendly team or request a brochure.

ESD Moisture Barrier Film Technical Data

| Electrical Properties | Typical Values | Test Method |

| Surface Resistance | | ANSI/ESD STM 11.11 |

| Interior | <10E11ohms | |

| Exterio | <10E11 ohms | |

| Metal | 100 ohms | |

| Static Shielding | <15 nJ | ANSI/ ESD STM11.31 |

| Static Decay | <0.03 seconds | EIA 541 |

| Charge Generation | < 100 volts | ** 15kV and 12% RH |

| Physical Properties | | |

| | | |

| Material Thickness: | 4.0mils+/-10% | |

| Puncture Strength | 10.0 lbs | MIL-PRF-81705D |

| Seam Strength | No separation | MIL -PRF-81705D |

| Heating sealing Conditions | | |

| Temperature | 300°F -400 °F | |

| Time | 0.6 -4.5seconds | |

| Pressure | 30 – 70 psi | ASTM D882 |

| Tensile Strength | >3,500 psi MD/TD | ASTM F-1249 |

| Water vaporTransmission (@100°F&90%RH) | <0.006grams/100 sq in/day | |

| | | |

| Visual inspection | No tears,holes,sctratches,etc. |

Produce progress:

Packaging

- Q: What products need plastic packing bags?

- Electronic products, clothing products, industrial products, some medical products, food and so on. What kind of plastic bags are the key?.

- Q: What kind of material is the packing bag of ceramic tile?

- There are three paper kraft paper composite film, color film, color film lamination, lamination, lamination and color printing paper, woven bags and other materials, can do

- Q: Why a lot of the packaging bag surface is silver foil?

- Because candies are also considering moisture side so many sweets are wrapped in wax paper (because the wax paper can prevent water entering)For example, chocolate is a special kind of candy, its melting point is 36 degrees, it is very easy to get the temperature melting in the hand, so the reason is tin tin foil, the hands of the temperature can be very good to pass out to prevent the chocolate melts quickly.

- Q: What about the use of plastic bags?

- Now all walks of life have the use of plastic packaging bags, only grades, such as the food market is the worst, supermarkets in general, and then to food packaging non-toxic environmentally friendly plastic bags. There are advantages and disadvantages. If it is a new material, the printing ink is also non-toxic. You can use it safely. If you use recycled materials, there is a foul smell. That's bad. What's more, we will bring plastic bags to the cooked food, it is best to buy from the supermarket, come back after the food will be taken out, to avoid food and plastic bags long-term exposure, chemical reaction products. That's bad for your health.

- Q: What material is the vacuum packing bag, please?

- Of course, there is also room temperature, the choice of this temperature under the condition of the sterilization method is irradiation sterilization.

- Q: What kind of material is the express package on the market now? It's dark in the outer grey.

- The materials used for express bags are generally HD-PE, which can be recycled and can be re packed into bags

- Q: Printing process of packaging bag

- When printing, through the extrusion of the scraper, the ink is transferred to the substrate through the mesh of the image part, so as to form the same picture and text as the original. The screen printing equipment is simple and easy to operate. The printing and plate making process is simple, low cost and adaptable. Printing screen printing application scope is broad common: color paintings, posters, name card is designed to cover commodity signs and textile printing and dyeing etc.

- Q: What are the requirements of the gas in the package?

- For example, some fruits, vegetables, air conditioning packaging, as well as cold meat also have the atmosphere of the tune (20% carbon dioxide, 80% oxygen), low temperature, preservation for about a week, to maintain fresh meat color, prevent browning!

- Q: What does "13 silk" in vacuum packing bag mean?

- The wire unit is 1/1000 points, the general use vernier caliper, micrometer, gauge with smaller, can be measured. According to the determination, a hair diameter of about five to seven silk (ie 0.05 ~ 0.07), "a trace" is a very small unit. The wire is called the habit of CMM, and other transformation between the length of the unit is:1 mm = 100 wire (tract)1 =10 =0.1 decimillimeter centimillimeter micrometer wire =1 =0.01 mm =0.001 cm =0.00001 meters

- Q: What's the size of the 5 kg vacuum bag, please?

- Now the standard of living has improved, basically vacuum packed bags. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

Send your message to us

Semi-transparent Static Film to Protect Electronical Parts

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords