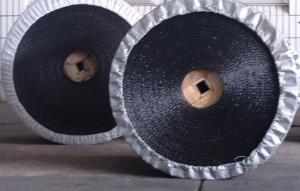

Semi-conductive Water-blocking Metal Shield Flame Retardant Wearing Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Application: It is mainly used for shielding layer of high voltage cable and extra-high voltage cable.

Property | Unit | TF-ZBTZD50 |

Thickness | mm | 0.5±0.05 |

Weight | g/m2 | 400±30 |

Surface Resistance | Ω | <500 |

Volume Resistance | Ω.cm | <1×103 |

Tensile Strength | N/cm | 1000N/1.5cm |

Oxygen Index | % | >60% |

Swelling Speed | mm/1`00` | 6 |

Swelling Height | mm/5`00` | 8 |

- Q: Blue belt principle is what?

- Blue will be packaged with packaging with heating to proper temperature in the air - water vapor to form a blue layer of the surface process.

- Q: The baggage for my American traveler's cloth is to be checked. Do you need a doggy belt? Will it protect the box?

- I think the main function of the strap is 21, prevent the box from being hit by an impact2, to prevent thieves at the airport to steal things in the box, because it will increase the difficulty of unpackingIf you don't want to box was scratched, can wear a cap.

- Q: What is the reason that the packing machine can not be put in?

- It may be the wrong model of the packing belt, too wide or too thick, or the way to wear it is wrong. The Qingdao moxa packing machine, in general, has a detailed picture of the inside of the packing machine door, which can be referred to.

- Q: Is the profit margin of the packing belt line large?

- How do you say this?! Want to get rich quickly is impossible, he is a steady business, slowly, was still relatively moist, is in trouble!

- Q: How much is a tin strap?

- The steel strip is wrapped in gunny cloth, with 1 or 2 plates of steel in each package (according to the specific type) and bound with iron strips.

- Q: How to identify the quality of a packaging belt?

- The above can not be confirmed, please again by fire, in the burning process of black smoke or quickly melt rapidly dropping, not good.6. use teeth bite: first to experience the new material PP (PP regeneration material) strength, and then contrast, if relatively soft, absolutely inside add PE.7., look at the incision section: rough and dry surface, no luster, poor quality.8.: as long as the submerged floating difference, if the above is not sure, or undecided, then only the test machine. Experience, whether good or bad, must be identified by machines, because it is the safest. Other materials can also be applied to the above, of course, they have to understand the nature of the new material first.

- Q: What's the function of the carton packing belt?

- The plastic strapping belt is divided into machine belts according to the method of use

- Q: What types of Baling straps are used for packing?

- Wooden boxes, color coated sheet, strip, steel plate, steel wire, welded pipe, aluminum ingot, magnesium ingot, zinc ingot baling etc. different zinc plating method of packing tape: hot galvanized steel packing belt because it is in the hot galvanizing production line, through continuous annealing, continuous hot dip galvanizing liquid steel is heated in a short time and the cooling performance than the original cold rolled sheet stamping. Electric galvanized belt in electroplating process, is not affected by the heating and cooling temperature, so the stamping is roughly the same. The original properties of cold rolled plate of the galvanized layer, without formation of fragile Fe Zn alloy layer, good ductility of galvanized layer but, because of its surface porosity, low intensity, easy to scratch, prone to dry paint pollution.

- Q: What's the difference between a strapping sheet and a steel package?

- Steel band (also known as PET) is a new alternative to steel strapping the international popular band, widely used in iron and steel, aluminum, brick, building materials, chemical fiber cotton, tobacco, paper, metal cans and other industries.

- Q: How much is a tin strap?

- The surface lubricating strip, reduce the friction resistance between the strip and strip between packaging and packaging, in order to make the packing strip tightening more firmly; the edge smooth edges, avoid packaging and packaging to scratch the rower.

Send your message to us

Semi-conductive Water-blocking Metal Shield Flame Retardant Wearing Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords