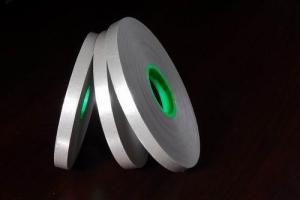

Fire-resistant Mica Tape with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Description:

Polycarbonate (Polycarbonate), abbreviated as PC, is a colorless, transparent, and non qualitative thermoplastic material. The flame retardant PC of the flame retardant PC in the combustion of carbon, so as to achieve the purpose of flame retardant.

Colorless and transparent, heat resistance, impact resistance, flame retardant, in the ordinary use of temperature have good mechanical properties. But not resistant to UV light. Compared with the same sex, the impact resistance, high refractive index, good processing performance of polycarbonate

2. Product Characteristic:

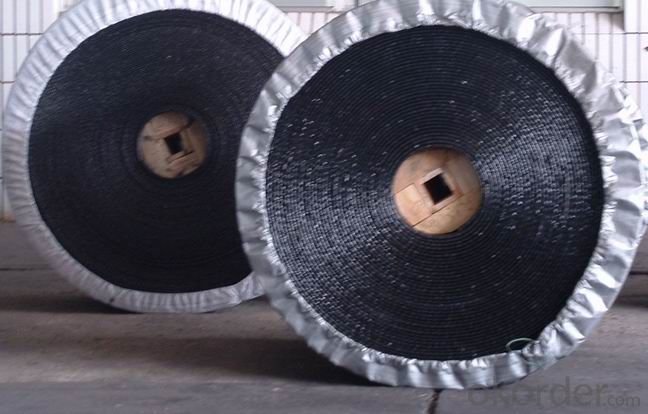

By the whole belt core after plastics PVC impregnated paste impregnated or sulfide made. The product has strength, has good flame retardant, antistatic, impact resistance, abrasion resistance, corrosion resistance and other properties.

3.Specification :

Model N/mm (tensile strength):

Grade 5 grade 6 grade 7 grade 8 grade 9 grade 4 grade 10 grade

680s 800s 1000s 1250s 1400s 1600s 1800s

Model 800s 1000s 1250s 1400s 1600s 1800s 680s

4. Reference Picture:

- Q: Blue belt principle is what?

- Blue will be packaged with packaging with heating to proper temperature in the air - water vapor to form a blue layer of the surface process.

- Q: What is the reason that the packing machine can not be put in?

- Tighten wheel belt did not stir, blocking the slip past

- Q: What is the reason that the packing belt of the packer is not glued?

- Packaging materials with the belt has a bearing, you may have this batch of packaging materials, raw materials doped more ingredients, and now on the market with the main component of polypropylene, commonly known as PP. A better pack should have a PP content of more than 95%. Other ingredients are complex, such as mixing calcium carbonate, talc, wollastonite, glass fiber and other inorganic fillers. If the ingredients are more, the hot-melt viscosity is poor. It is recommended that you provide the supplier with the matching parameters.

- Q: What kind of joints are used in the packing belt?

- Hot dip lap pack.Hot melt lapped by electrothermal welding, packing machinery high-frequency welding and ultrasonic welding and heating method, plastic surface heat melting, two with end face lapping up melting under pressure, to maintain a certain period of time, to be melted surface condensation, adhesive plastic belt joint way. Features: hot lap package is a package of new, suitable for polypropylene plastic bag, polypropylene plastic belt with iron because if the button is fixedly connected with the mechanical strength, only 50% of that of the base material, adhesive connection does not apply. The excuse is firm and beautiful, but it can not be untied.

- Q: What kind of joints are used in the packing belt?

- Iron buckle packing.The one-way tensioner ratchet, the packing tape tensioning, then pack joints placed a hasp, hasp and clamps make wrap two layer packing belt, and the tooth shaped hasp side teeth bump, bite strap does not cause the loose. Usually made of galvanized sheet iron buckle, the operation to choose to adapt according to the specifications of the metal packing belt type.

- Q: Production process of PP packing belt

- Finally, the embossing, stretching after the packaging belt, after two patterns of pressure roller, it will be pressed on the pattern, its role is to increase friction in use, do not slip, from the appearance of looking handsome.

- Q: What adhesive tape do you use?

- Common polyethylene, polypropylene resin as the main raw material, but also to nylon and polyester, polyester and the tensile strength of nylon strap, and polyethylene and polypropylene strapping polypropylene with low cost, good elasticity, can be selected according to different material strapping needs. ;

- Q: How to identify the quality of a packaging belt?

- Method: blow after the fire, iron objects quickly contact the melt, and then quickly opened, look at the wire forming is not uniform, uniform is good, Dora several times after the wire will overlap, opened again, to see if it has no elasticity, can not be opened again without fault, no fault the distance or break is good.

- Q: Is the profit margin of the packing belt line large?

- Packing belt production line this is not really, but if it is packaged with steel belt, such as Wuxi, Xiao Qi can find him

- Q: Why are packing machines always unstable?

- The voltage of the supply is abnormal.This machine should use 220V voltage. Many factories voltage is often inadequate, if the use of long cable will cause a voltage drop so that the soup temperature becomes lower, even in fastened when burned motor.

Send your message to us

Fire-resistant Mica Tape with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches