Semi-Auto Straw Baler, Rice Straw Baling Machine, Coconut Fiber Baler Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

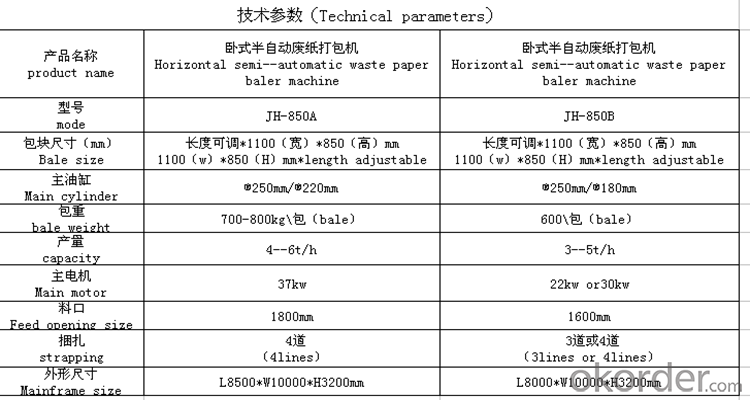

Specification

Product Application

The waste paper baler machine is used for extruding and forming the waste paper and the similar products in the normal condition,and use the special packing belt bale forming ,make its volume greatly reduced,so as to cchieve the purpose of reducing the volume of transport,saving freight and increasing the efficiency of the enterprise . introducing advanced technology of similar products at home dad abroad.

Name: line

All bearings, pairs of motion, guide rails, etc. shall be provided with lubrication refueling points, and have a prominent logo. Lubrication points that are not convenient for direct refueling shall be led to corresponding lubrication lines and refueling points, and be placed in a safe and convenient place for

Name: system

1、The device has alarm indicator, fault display and prompt function

2、Cooling tower cooling system is adopted so that the equipment can maintain normal operation below 60° for a long period of time;

3、Lubrication system: automatic lubrication system reduces mechanical wear, reduces mechanical noise, and stabilizes mechanical operation.

Name: Fixed pressure package

Fixed pressure package length: high strength train rail joint structure; and timer control package length.

Name: Bliwing Cylinder

Name: Bliwing Cylinder

1、Stranding mechanism: gear transmission, hydraulic winding; shred.

2、Wire tie method: hydraulic hook line, trimming system, and 3 lines.

3、Bottom structure: roller track, track with wear-resistant high-quality steel 20mm. Bottom support ribs 180 GB channel.

4、Pushing system: roller device, reducing the mechanical resistance of the main hydraulic cylinder return movement, effectively increasing the speed of pushing the package. The composition of the pusher head is welded from 20mm pure steel plate with a rib thickness of 20mm.

5、Fixed pressure package length: high strength train rail joint structure; and timer control package length.

6、Lubrication system: automatic lubrication system reduces mechanical wear, reduces mechanical noise, and stabilizes mechanical operation.

Our Service

Pre-Sales Service

1.Your inquiry will be replied within 24 hours.

2.Any questions, you could email us or call directly.

3.24 hours technical support by e-mail.

After-Sales Service

One year guarantee period after installation.

During this guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, we will provide them at cost price.

process

Waste paper bins, scraps, etc. are manually collected or conveyed by conveyor belts onto the feeding conveyor belt. The feeding conveyor belt conveys these materials to the host compression chamber. When the material reaches a certain height, the main cylinder drives the pressure plate to move forward. When compressing the material, when it reaches the front end, the main oil cylinder is reset backwards and waits for feeding. When the material is full and reaches a certain height, the main oil cylinder drives the pressure plate forward to compress the material and repeat the above process. When the compressed material reaches the set length, the pressure plate will stop at the front end and will not be reset afterwards. The hooking machine will stop when it moves forward to the extreme end, and the hooking machine will move backward to start the hooking line work. At the end of work, push the tank cylinder to work, push the wire and thread trimmer forward to the working position, work on the bundled wire motor, start the bundled wire, and after the bundled wire is completed, stop the bundled wire, trim the cylinder work, and cut the bundled bundle. Iron wire. Push tank cylinder reset, the main cylinder reset, a work process is completed. The above working process is completed automatically by the PLC intelligent control, and the entire process of feeding, compressing, hooking, binding, trimming, and packaging is automated. Touch screen control, good man-machine interface, whole process safety monitoring, failure, safety detection alarm, display function. Full hydraulic drive, stable operation, easy control and low failure rate.

- Q: What is the general packing cost of beer beverage packaging?

- Beer beverage hot shrink packaging generally use PE heat shrinkable film, packaging temperature is usually in accordance with the film material and thickness to set,

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- Wrapping of objects of different shapes according to their appearance.

- Q: What is the price of a small jujube packing machine?

- What is the price of a small jujube packing machine?

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- This situation is best to find after sale processing, you have difficulty adjusting normal

- Q: A & B two sets of packaging machines, at the same time packaging quality of 500 kilograms of goods

- 10 bags were randomly extracted from each of them, and the actual quality was measured as follows: (unit G)A: 501500503506504506, 500498497495B: 503504502498499501, 505497502499

- Q: Color code positioning of packaging machinery

- Color code positioning and photoelectric trackingIn order to ensure the integrity of the mark on the finished package, it is usually printed on the package for positioning.

- Q: The role of packaging equipment in packaging equipment

- (4) it can reduce labor intensity and improve working conditionsThe labor intensity of manual packaging, such as volume, weight heavy manual packaging products, both the consumption of physical strength, and safety; and for small and light products, due to high frequency, easy to make the action monotonous, worker occupation disease.(5) labor protection for workersFor some serious impact on health products, such as serious dust, toxic products, irritating, radioactive products, manual packaging is a health hazard, and packaging machinery can be avoided, and can effectively protect the environment from being polluted.(6) it can reduce the packing cost and save the storage and transportation expensesFor loose products, such as cotton, tobacco, silk and hemp, the compression packing machine can reduce the volume and reduce the packing cost. At the same time, due to the reduction of large volume, in order to save storage capacity, reduce storage costs, is conducive to the transport.

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- Take the food packaging machine for example, if only from the hardware, then you can ask when you buy the degree of automation, semi-automatic or fully automatic, the use of steel ah,

- Q: What is a packaging machine?

- Meet the needs of mass production and meet the requirements of clean sanitationUsually some non-standard equipment, the common is pneumatic and simple combination of electrical components, to meet the requirements of factory automation

- Q: What does the mechanical equipment include?

- Hydraulic lifting track machineHydraulic tamping machine, rail sawing machine, rail machine

Send your message to us

Semi-Auto Straw Baler, Rice Straw Baling Machine, Coconut Fiber Baler Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords