Self Adhesive Aluminum Strips for Color Coated Aluminum Roofing Coil Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Exterior: tunnels,column covers , renovations...

(2).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

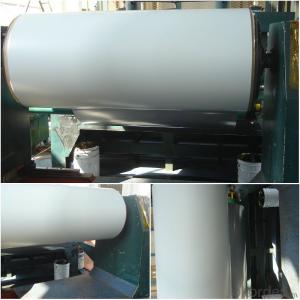

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Is it good to drive a wheeled excavator or an aluminum belt?

- How many people do you say you drive, or do you drive more tanks? However, the western development is over, the excavator is not fragrant. Go to the second-hand Internet to see the excavator is very cheap. Take mine. Thank you。。。

- Q: What precautions should be taken into account when handling aluminum strips to ensure safety?

- <p>When using aluminum strips, safety concerns include avoiding skin contact with sharp edges to prevent cuts, ensuring proper ventilation to prevent inhalation of aluminum dust which can cause respiratory issues, and using protective eyewear to shield against flying debris. Additionally, it's crucial to handle aluminum strips carefully to prevent them from becoming projectiles, especially when cutting or bending. Always use appropriate tools designed for metal work and follow safety guidelines specific to the task at hand.</p>

- Q: This question asks about the various forms or configurations that aluminum strips can take in terms of their shape.

- <p>Aluminum strips are available in various shapes to meet different industrial and manufacturing needs. Common shapes include rectangular, square, and circular strips. Rectangular strips are the most common and can be found in various thicknesses and widths. Square strips are less common but still used in specific applications. Circular strips, also known as aluminum wire, are used in electrical applications and other areas requiring a round cross-section. Other shapes like triangular, hexagonal, or custom profiles can also be produced but are less standard and typically require specialized manufacturing processes.</p>

- Q: 25 square metres of aluminium wire. Can you bring up 4 sets of two air conditioners?

- According to the load calculation, 4 sets of two air conditioners, as long as the wire reached 8 square, you can drive. Your 25 wire can drive. But it is recommended that you use copper wire as a guide wire. The quality and service life of the copper wire is much better than that of the aluminum wire.

- Q: The question asks for the cost of an aluminum strip.

- <p>The cost of an aluminum strip varies greatly depending on factors such as its size, thickness, quality, and market demand. Prices can range from a few dollars for small, thin strips to hundreds or even thousands for large, thick, or high-quality strips. To get an accurate price, it's best to check with suppliers or online marketplaces for current rates based on the specific dimensions and grade of aluminum you require.</p>

- Q: Is it possible to use aluminum strips to construct a solar reflector system for residential or commercial purposes?

- <p>Yes, you can use aluminum strips to create a solar reflector system for your home or business. Aluminum is a reflective material and can be shaped into strips to reflect sunlight. These strips can be arranged in a way to direct sunlight towards solar panels or into specific areas to reduce the need for artificial lighting and heating. However, for optimal efficiency, you should consider the angle of reflection, the positioning of the strips relative to the sun's path, and the overall design of the system. Consulting with a professional in solar technology can help ensure that your solar reflector system is effective and safe.</p>

- Q: Is it possible to construct awnings or canopies using aluminum strips?

- <p>Yes, aluminum strips can be used to make awnings or canopies. They are lightweight, durable, and resistant to corrosion, making them suitable for outdoor applications. Aluminum's strength and flexibility allow it to be bent and shaped easily, which is ideal for creating the curved or angled structures often seen in awnings and canopies. However, it's important to ensure that the aluminum is of sufficient gauge to support the weight and withstand environmental stresses. Additionally, proper sealing and treatment are necessary to prevent water damage and maintain the longevity of the structure.</p>

- Q: Is it possible to create a more energy-efficient roof using aluminum strips compared to other materials?

- <p>Yes, aluminum strips can be used to create a roof that is more energy-efficient than some other materials. Aluminum is a good conductor of heat, which can help in reflecting sunlight and reducing heat absorption, thus lowering cooling costs. Additionally, aluminum roofs can be designed with energy-efficient features such as solar reflectance and thermal emittance properties, which can further enhance their energy efficiency. However, it's important to consider the overall design, insulation, and installation quality to maximize energy efficiency.</p>

- Q: What types of aluminum strips are known for their durability?

- <p>Yes, there are several types of aluminum strips known for their durability. One of the most durable types is 7075 aluminum, which is an alloy that offers high strength and is commonly used in aerospace applications. Another durable option is 6061 aluminum, which is a heat-treatable alloy with good mechanical properties and is often used in construction and transportation. Additionally, 3003 aluminum is known for its corrosion resistance and is used in applications where durability against weathering is important. The durability of aluminum strips can also be enhanced through various surface treatments and coatings.</p>

- Q: Is it possible to use aluminum strips for creating electrical connections?

- <p>While it is technically possible to use aluminum strips to make electrical connections, it is not generally recommended due to several reasons. Aluminum has a higher electrical resistance compared to copper, which is the standard material for electrical wiring. It is also more prone to corrosion and can form aluminum oxide, which is an insulator, leading to poor connections over time. Additionally, aluminum expands and contracts more than copper with temperature changes, which can cause connections to loosen. For reliable and safe electrical connections, copper or other approved materials should be used.</p>

Send your message to us

Self Adhesive Aluminum Strips for Color Coated Aluminum Roofing Coil Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords