Seamless Steel Pipe Low Price Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、specific of CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B:

ASTM A106, ASTM A53, ISO3183-2-1996

● Application: To be used for conveyance of petroleum, gas and conveyance of other fluid

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

Standard: APL SPEC 5CT

● Application:Tubing is used to extracting extract petroleum andnatural gas from a well.Casing serves as walls of well.

2、Main advantage of CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B :

• accuracy of manufacturering is high

• long life good after sales service

• Small inertia resistance High strength

• Strong heat dissipation ability

• Good visual effect

• Reasonable price good quality long life and best service

3、CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | He Bei, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

4、Packaging & Delivery of CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 30-45days after received 30%TT |

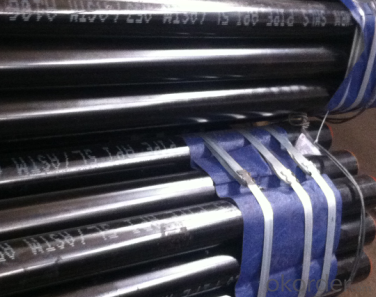

CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B Images:

FAQ of Seamless Pipe ASTM A106/53:

①Quality

Our products are manufactured strictly according to national and internaional standard, every pipe will be tested before delivered out. we could provide the quality certifications and all kinds of testing report as long as you need, please just ask us for it.

Guaranteed: we promise 100% refund If products’ quality don’t accord to discription as we give or the promise before you place order.

②Price

we are factory and be able to give you lowest price with the same good quality , and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given accordinood to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

Why us?

● Professional teams ensure a high efficiency of your purchase

▲ Professional sales team

▲ Professional engineering and technology team

▲ Professional exportation and contract processing/management team

▲ Professional cooperators and partners

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

- Q: What is the primary purpose of steel pipes?

- The primary purpose of steel pipes is to transport fluids and gases, such as water, oil, and natural gas, over long distances in a safe and efficient manner.

- Q: What are the properties of steel that make it suitable for pipe manufacturing?

- Steel is an ideal material for pipe manufacturing due to its various properties, including high strength, durability, and resistance to corrosion and extreme temperatures. It can withstand high pressure and can be easily fabricated into different shapes and sizes, making it versatile for various piping applications. Additionally, its smooth surface ensures efficient flow of fluids and reduces friction losses.

- Q: How do steel pipes handle chemical exposure?

- Steel pipes are highly resistant to chemical exposure due to their inherent corrosion-resistant properties. The steel used in pipes is often coated with protective layers or made from stainless steel, which makes them capable of withstanding the effects of various chemicals without deteriorating or reacting. This allows steel pipes to handle chemical exposure effectively and maintain their structural integrity over time.

- Q: What are the different threading options for steel pipes?

- The different threading options for steel pipes include tapered pipe threads (NPT/NPTF), straight pipe threads (NPS/NPSM), and mechanical threads (such as API threads). These threading options provide different levels of sealability, compatibility, and ease of installation, allowing for a variety of applications and connections.

- Q: What are the factors to consider when selecting steel pipes for a specific application?

- When selecting steel pipes for a specific application, several factors need to be considered. The key factors include the required strength and durability, corrosion resistance, temperature and pressure requirements, size and dimensions, cost considerations, and compatibility with other materials or systems. Additionally, factors such as the intended environment, installation requirements, and regulatory compliance should also be taken into account to ensure the optimal selection of steel pipes for the particular application.

- Q: How are steel pipes used in the telecommunications infrastructure?

- Steel pipes are commonly used in telecommunications infrastructure for the installation of underground cables. These pipes provide protection and support to the cables, ensuring their longevity and efficient functioning. Additionally, steel pipes are used for the construction of telecommunication towers, providing a sturdy framework for antennas and other equipment.

- Q: Can steel pipes be used for stormwater management systems?

- Yes, steel pipes can be used for stormwater management systems. Steel pipes are a commonly used material for stormwater management due to their durability, strength, and resistance to corrosion. They can effectively carry and transport stormwater, making them suitable for various applications in stormwater management systems.

- Q: Can steel pipes be used for conveying corrosive substances?

- Steel pipes can be used for conveying corrosive substances, but it is important to choose the right type of steel and consider additional protective measures. Stainless steel pipes, for example, are highly resistant to corrosion and can handle a wide range of corrosive substances. However, it is crucial to consider the specific corrosive properties of the substance being conveyed and the concentration levels. In some cases, additional protective coatings or linings may be necessary to prevent corrosion and ensure the longevity of the steel pipes. Regular maintenance and inspection are also essential to detect and address any signs of corrosion to prevent leaks or failures in the piping system. Overall, steel pipes can be used for conveying corrosive substances, but proper material selection, protective measures, and maintenance are vital to ensure safe and efficient operations.

- Q: How long do steel pipes last?

- There are several factors that can influence the lifespan of steel pipes. These factors include the quality of the steel used, the installation environment, and the maintenance and care provided to the pipes. Steel pipes are generally recognized for their durability and long life. When properly installed and regularly maintained, steel pipes can endure for many decades, sometimes even surpassing 50 years. However, it is important to consider external factors that can greatly impact their lifespan, such as corrosion, exposure to extreme temperatures, and chemical reactions. To ensure the reliability and functionality of steel pipes for an extended period, it is crucial to conduct regular inspections, make timely repairs, and apply protective coatings.

- Q: How are steel pipes used in the manufacturing of food processing equipment?

- Steel pipes are commonly used in the manufacturing of food processing equipment due to their durability, strength, and resistance to corrosion. These pipes are used to transport various food products such as liquids, powders, and gases within the equipment. They are also utilized in the construction of frames, supports, and structures for food processing machinery, ensuring stability and longevity. Additionally, steel pipes are often employed in the creation of heat exchangers, which are crucial for heating or cooling purposes in food processing equipment.

Send your message to us

Seamless Steel Pipe Low Price Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords