SEAMLESS PIPE 1/2"-3" API 5L A53 A106 GR.B 20# GOOD PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Seamless pipe possesses a hollow section and without seam around the strip steel. It is made with solid bar or steel ingot by perforating machine. Seamless pipes are considered to be stronger and more durable.

2、Main Features of the Seamless Pipe:

• High working accuracy

• The higher strength

• Small inertia resceistan

• Strong therming dissipine ability

• Good appearance

• Reasonble price

3、Seamless Pipe Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range: OD: 21.3-610mm, WT:6-70mm, length:6-12m or according to the requirement of clients.

3) Executive standards: GB, ASME API5L.ASTM A 106/A53,Despite of the above standards, we can also supply seamless steel pipe with standard of DIN, JIS, and so on, and also develop new products according to the requirements of our clients!

4) Surface: black lacquered, varnish coating or galvanized.

5) Ends: Beveled or square cut, plastic capped, painted.

6) Packing: bundles wrapped with strong steel strip, seaworthy packing.

4、Packaging & Delivery:

Packaging Details: | seaworthy package, bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe:

①How is the quality of your products?

Our products are strictly in accordance with international and domestic standard. We test on every pipe before delivery. Any quality certification or testing report you want to see, please tell us. If products’ quality is not in accordance with description as we provide or the promise before you place order, we promise 100% refund.

If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about the price?

Yes, we are factory and be capable of offering you the lowest price. One of our policy is to save time and be absolutely honest with our business relationship.

③Why should you choose us?

Our service formula: good quality + good price + good service=customer’s trust.

SGS test is available. Customer inspection before shipping is welcome. Third party inspection is OK.

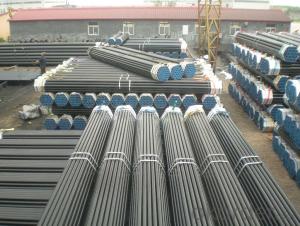

6、Seamless Pipe Images:

- Q: What does GALV mean in a steel tube?

- Steel pipe is not only used to transport fluid and powder solid, exchange heat energy, and manufacture mechanical parts and containers, but also is an economic steel. It can reduce weight and save 20 to 40% of metal by using steel pipe to make building structure, network frame, prop and mechanical support. Moreover, it can realize factory mechanization construction. Using steel pipe to manufacture road bridge can not only save steel, simplify construction, but also greatly reduce the area of coating protective layer, save investment and maintenance cost.

- Q: Can steel pipes be used for marine applications?

- Yes, steel pipes can be used for marine applications. Steel pipes have high strength and durability, making them suitable for various marine environments and applications such as offshore drilling, shipbuilding, and underwater pipelines. The corrosion-resistant properties of steel pipes can be further enhanced by applying protective coatings or using corrosion-resistant alloys, ensuring their long-term performance in marine conditions.

- Q: Will the steel tube dance?

- The steel tube dance tube has a rotating steel tube and a fixed steel tube, so that different types of steel pipe can be chosen according to the type of pipe dance performed by the dancer.

- Q: How do you calculate the flow rate in a steel pipe?

- When calculating the flow rate in a steel pipe, several factors must be taken into consideration. The primary factor to consider is the cross-sectional area of the pipe, which can be determined using the formula A = πr², where A represents the cross-sectional area and r represents the radius of the pipe. Afterwards, it is necessary to ascertain the velocity of the fluid moving through the pipe. This can be accomplished by utilizing the equation v = Q/A, where v denotes the velocity, Q represents the volumetric flow rate, and A represents the cross-sectional area of the pipe. To determine the volumetric flow rate, one can employ the equation Q = AV, where Q represents the volumetric flow rate, A represents the cross-sectional area, and V represents the average velocity of the fluid. Furthermore, it is essential to take into account the properties of the fluid being transported through the pipe. Factors such as density and viscosity can impact the flow rate. In conclusion, the flow rate in a steel pipe can be calculated by determining the cross-sectional area of the pipe, calculating the velocity of the fluid, and considering the properties of the fluid being transported.

- Q: How are steel pipes used in the construction of natural gas power plants?

- Steel pipes are used in the construction of natural gas power plants for various purposes such as transporting natural gas from the source to the plant, distributing gas within the facility, and carrying exhaust gases away from the plant. They are essential for maintaining a safe and efficient flow of natural gas throughout the power plant's infrastructure.

- Q: Can steel pipes be used for the construction of railway tracks?

- No, steel pipes cannot be used for the construction of railway tracks. Railway tracks are typically made of steel rails that are specifically designed and manufactured for this purpose. Steel pipes lack the necessary shape, strength, and dimensions required for supporting heavy loads and facilitating the smooth movement of trains.

- Q: What are the safety considerations while handling steel pipes?

- When handling steel pipes, some key safety considerations include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toe boots to protect against potential injuries. It is important to be cautious of the weight and size of the pipes, using proper lifting techniques and equipment to prevent strains or accidents. Additionally, workers should be mindful of the sharp edges and potential for cuts or punctures, ensuring they have a clear and organized workspace to minimize the risk of tripping or falling. Regular inspections of the pipes for any damages or defects are also crucial to prevent accidents and maintain a safe working environment.

- Q: What's the difference between a rectangular tube and a rectangular steel tube?

- The classification of rectangular tube: steel pipe seamless steel pipe and welded steel pipe (tube) hot-rolled seamless tube, seamless tube, seamless tube, welded tube extrusion. The welded square pipe is divided into two parts:(a) according to the process of arc welding - resistance welding tube, square tube (high frequency and low frequency), welding square tube, welding square tube furnace (b) according to the weld - welded square tube, spiral welded pipe.

- Q: What are the different methods of heat treatment for steel pipes?

- Some of the different methods of heat treatment for steel pipes include annealing, quenching, tempering, normalizing, and stress relieving.

- Q: Can steel pipes be used for fencing?

- Yes, steel pipes can be used for fencing. They are a popular choice for fencing due to their strength, durability, and ability to withstand harsh weather conditions. Steel pipes provide a sturdy and secure barrier, making them suitable for various fencing applications such as residential, commercial, and industrial settings.

Send your message to us

SEAMLESS PIPE 1/2"-3" API 5L A53 A106 GR.B 20# GOOD PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords