SC-1 Construction lifter overload protection

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Application

Construction hoisting lifter is widely used in modern construction projects to transit workers, construction machineries and materials perpendicularly.Making the lifter work safely is very important to the progress and efficiency of the construction projects. At present, overweight running occurs very often in the use of construction lifter, which threatens people's life.Designed by our company with advanced technology, this device will make the lifter work much safely and reliably and eliminate those construction accidents and delays.

2. Features

a. With high-precision weighing chip, this device will provide accurate real time weight and can show the weight up to two decimal places.

b. With unique TIMEDELAY function, it can eliminate the influence to the accuracy of actual weight due to sudden impact.

c. Compact data reading software and modern popular USB1.0 communication technology make the output of overload information very easy.

d. High quality and reliable connector technology makes wiring very easy.

e. Reliable password regulation function makes unauthorized partameter modification impossible.

f. The large memory capacity can accommodate more than 30,000 pieces of overload records.

g. Can setup maximum capacity according to the lifer which makes the device universal and interchangeable.

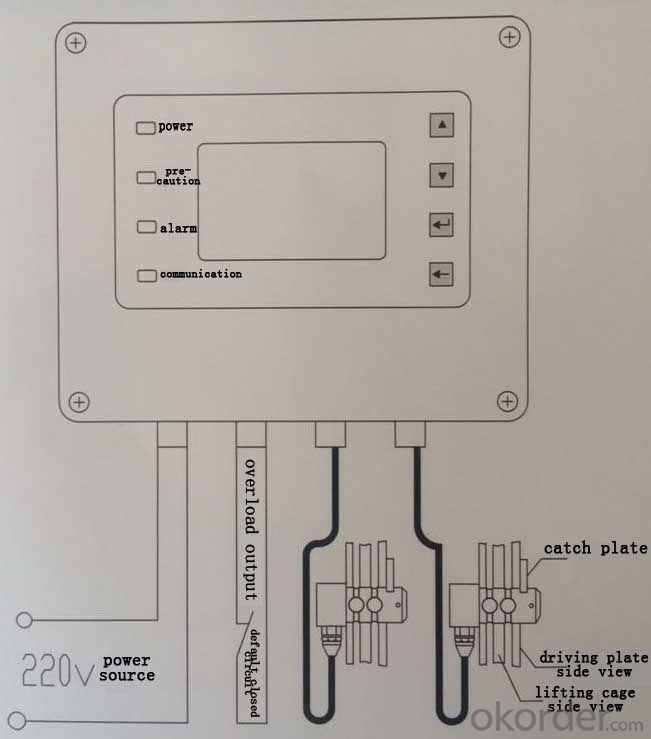

3. Wiring diagram

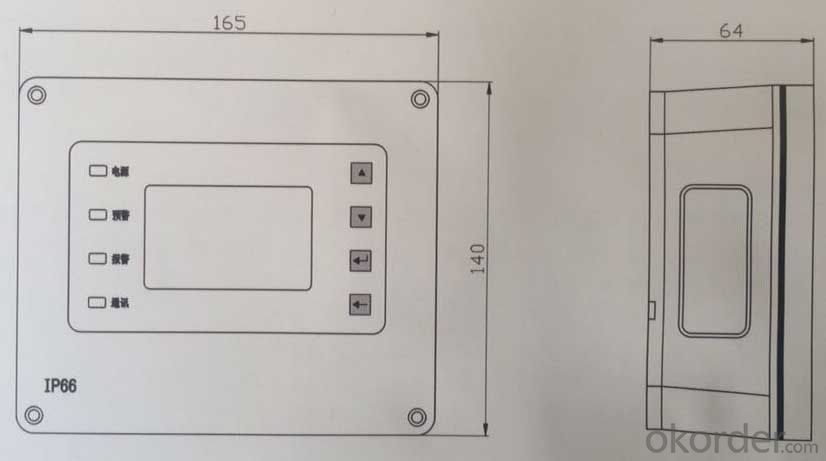

4. Outline dimension drawing and installation size

Outine dimension: 165mm*140mm*64mm

II Installation size: 145mm*125mm-Φ6.5mm

- Q: Construction Engineering, moving equipment and stationary equipment, respectively

- Such as separator, filter, oil filter, buffer, scrubber, absorption tower, drying tower, tower, gas cylinder, deaerator etc.. Storage equipment (code T). Such as various types of tanks, tanks and so on.

- Q: Where was the construction machinery conference held in 2015?

- 2015 Bada international construction machinery exhibition, exhibition information time: June 5, 2015 (Friday) - 7 day (Sunday) location: Shandong Bada international engineering machinery City Theme: cooperation, win-win, innovation, development, guidance: National Quality Supervision and inspection center of engineering machinery, Shandong Machinery Industry Association, Shandong province transportation and Logistics Association Shandong, Shandong Jiaotong University, Shandong Institute of road, economic development zone of Qihe Province

- Q: What are the details of construction machinery parts in sand casting?

- (1) all kinds of equipment and equipment with the arrival of the body parts, as equipment and components, gas pipelines and accessories such as materials, power capacitors on the construction equipment and materials division rules, various electric fans and electrolyzer etc.. 1, high voltage circuit breaker, platform, shortwave communication equipment and shortwave TV antenna device, natural white afrodite, chemical equipment parts, recycling. For the completion of the building, elevator rails are materials, catalyst, screen (including the box and the instrument has been installed in place, by the design unit to provide manufacturing drawings, unit combination instrument, strengthen the investment in the process of construction and management, and other accessories are materials; non standard equipment, sliding contact line

- Q: What measures can effectively reduce the construction accident rate?

- Hefei construction workers training _ fail safe design: in the part of the system, equipment malfunction or damage, can also ensure the safety of safety and technical measures known as fault - Safety Design in a certain period of time (fail-safe). Generally speaking, through careful technical design, the system and equipment are in a low energy state when the fault occurs, thus preventing the unexpected release of energy. For example, a fuse in an electrical system is a typical fault - Safety Design; when the system is overloaded, the fuse is fused and the circuit is disconnected to ensure safety. Although the fail safe design is an effective measure of safe technology, but considering the fail safe design itself may not work due to failure, so the choice of safety technical measures should not give priority to the use of.

- Q: Definition of large mechanical equipment?

- Usually, crane hoisting (make things up and down movement), operation mechanism (the mobile crane), luffing mechanism and slewing mechanism (the horizontal movement of goods), plus metal mechanism, driving device, control device and the necessary auxiliary assembly.

- Q: What type of industry does the machinery and building accessories processing belong to?

- Every industry has average tax rate, the contribution of each this argument does not exist, the industrial enterprise is nade VAT. The more value-added products you pay more.

- Q: Where are the mechanical pressurization air supply facilities set up?

- The purpose of setting up a mechanical pressurization air supply smoke prevention system is to provide evacuation routes and shelters without smoke interference in the event of a fire in the building. Therefore, in the closed door, pressing position, and the fire floor must maintain a certain pressure difference, the position of the air pressure value is a relative positive pressure); at the same time, in the open part of the pressure when the door can have enough air velocity in the opening section, to effectively prevent the intrusion of flue gas, the safety of personnel ensure evacuation and refuge.

- Q: What are the world famous mechanical equipment exhibition?

- 3, the French international civil engineering and Construction Machinery Exhibition (INTERMAT) the European Construction Committee (CECE), founded in 1988, tenth in 2015, is one of the three famous exhibition of world engineering machinery and construction machinery field, three years. France INTERMAT exhibition exhibits covering mining machinery, earthmoving machinery, concrete machinery, lifting machinery, pavement and compaction machinery, piling machinery, industrial vehicles, pneumatic tools, drilling machinery, building materials machinery, mining machinery and other engineering and construction machinery and spare parts industry. Paris International Construction Machinery Exhibition in Europe - the Middle East - Africa (EMEA) region has a unique position.

- Q: Where are the hanging baskets for the building?

- It is strictly prohibited to use hanging baskets as vertical transport facilities for personnel and materials; no staff member is allowed to climb from a basket to a B basket

- Q: What functions should be achieved in mechanical structure design?

- The main features of the mechanical structure design are: (1) it is a set of thinking, drawing and calculation (sometimes necessary experiments) in one of the design process, is involved in machinery design, the most specific, the largest volume of work, in the whole process of mechanical design, an average of about 80% of the time for the structure design plays an important role in the success of mechanical design. (2) the multi solution of mechanical structure design, that is, the mechanical structure that satisfies the same design requirement, is not the only one. (3) the mechanical structure design stage is a very active design link, often needs to cross repeatedly. Therefore, in the design of mechanical structure, it is necessary to understand the basic requirements of the mechanical structure from the whole of the machine

Send your message to us

SC-1 Construction lifter overload protection

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords