S816H Road Roller Buy S816C Road Roller at Okorder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name:

Parameter:

| Type | Unit | S816C |

| Operating weight | kg | 16000 |

| Load on front drum | kg | 9900 |

| Load on rear wheels | kg | 6100 |

| Drum width | mm | 2130 |

| Static linear load | N/cm | 464 |

| Vibration frequency(Low/High) | Hz | 28/35 |

| Nominal amplitude(High/Low) | mm | 1.86/0.88 |

| Excitation force(High/Low) | KN | 320/235 |

| Travel speed | km/h | 0~12 |

| Steering angle | ° | ±33 |

| Swing angle | ° | ±10 |

| Theoretical gradeability | % | 55 |

| Min. external turning radius | mm | 6415 |

| Engine model | Cummins B5.9 | |

| Engine power | kw | 125 |

| Rated engine speed | r/min | 2200 |

| Engine oil consumption | g/kW.h | 232 |

| Hydraulic oil tank capacity | L | 240 |

| Fuel tank capacity | L | 240 |

Advantages:

state-owned company

fortune 500 company

AAcustom

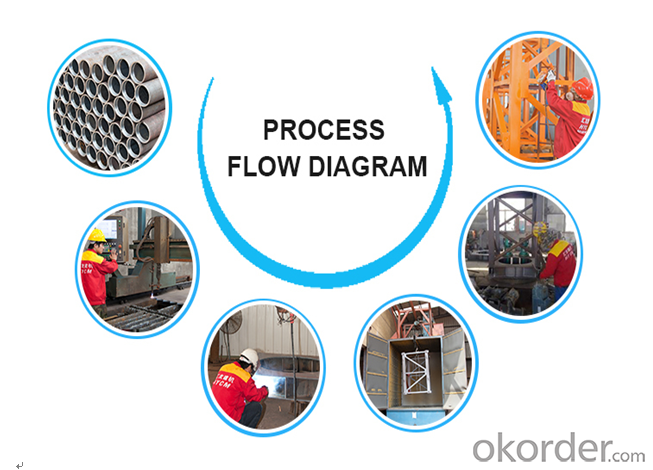

Why choose us?

1 sincre

CNBM International is a state company, now is one of the largest state-owned group cooperation in China! All the equipment such as tower cranes, produced by CNBM are compliant with the national level quality.

2 professional

Our engineers will at your services 24hours to solve all your tower crane installation and other questions. Our goal is to provide the best professional services.

3 quality

CNBM International’s tower crane have strict quality control, only the best quality products can pass the test.

4speed

We have professional sales team to guarantee your reply within 12hours to save your precious time.

5 After sales

If the tower crane has any problems, we will solve your problems in first time.

Inquies FAQ

My dearest friend, if you want to buy our tower cranes, please tell us the following parameters. And we will make the most suitable project for!

1. Building height or tower crane working height.

2. Max load capacity and tip load capacity.

3. Span or jib length

4. Other Special requirements

- Q: How often do rubber tyred rollers maintain?

- Generally speaking, the inspection items are as follows:1. Check tyre condition / wear and adjust pressure if necessary;2. Lighting system inspection (lights, lights, emergency lights, luggage compartment lights, passenger room lights, glove boxes, lights, dashboard warning lamps, etc.);

- Q: Roller brake lock why

- 3, wear plate return tension spring failure;4, the brake master cylinder push rod to adjust properly, there is no freedom of travel (four wheel lock);

- Q: C1 can I open the roller?

- You can apply to the local safety supervision department.

- Q: The front wheel diameter of the roller is 1.6m, and the width is 2m. What is the area of the roller that rotates for one week? M2

- Solution: it is known that the front diameter of the roller is 1.6 meters and the width is 2 meters,The front wheel is rotated for one week, the area of the roller = the front wheel's perimeter * width=3.14 * front wheel diameter * width=3.14 * 1.6 * 2=10.048 square metersA: the front wheel is rotated for one week. The area of the roller is 10.048 square meters.

- Q: OGFC why the use of less than 12 tons of steel tube roller

- Because it should be careful with vibration rolling and roller roller compaction, and pay attention to avoid excessive grinding. At the beginning of rolling, the opportunity of pressing the road is closely followed, and the paver should not be too spaced. After the paving, the initial degree of compaction is great. It has been proved by practice that the direct rolling process can be directly applied to the complex pressure process without serious deterioration, otherwise, it should be rolled according to the requirements of the SMA pavement.

- Q: Vibratory roller pressure and steel roller compacted what is different

- You should make the cement stabilized layer of double steel wheel vibratory roller, you should first use vibratory roller vibration compaction, and then do not open vibration to smooth surface. Just do not open the vibration pressure several times, the static pressure only to surface dense, but the bottom is still more loose

- Q: How much for an hour, how much money a day, oil?

- Your question is incomplete. If it is a vibratory roller, it can be divided into double wheel and single steel wheel. Single steel wheels are used in earthworks and crushed stone subgrade. Double steel wheels are used on asphalt.

- Q: What are the world famous manufacturers of roller compactors?

- World rollers are well-known manufacturers mainly in Germany, Sweden, the United States and japan. The roller mechanism before several manufacturers mainly in the United States Ingersoll Rand (INGERSOLL RAND, Ingersoll Rand note: the roller's business in 2007 sold to Volvo building Volvo equipment) and Caterpillar (CATERPILLAR), Germany's BMW (BOMAG) and Wittgen (WIRTGEN), Sweden Dynapac (DYNAPAC in Japan, Sakai) (SAKAI).

- Q: Road roller skills

- The 3 point line eyes a point, I went to see behind the engine exhaust pipe cover {also see the count} a point, when walking the rut pressure a point, back when the eyes see the machine lid point in the rut around too far will not bend too!

- Q: What about Luo Jian Road Roller?

- In the domestic goods are on the level, the brand is very old, the higher price, the price cheaper than Xugong, Xiagong, quality than Ketai, through good.

Send your message to us

S816H Road Roller Buy S816C Road Roller at Okorder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords