Rv Plastic Water Pipe Fittings - User-Friendly PPR Pipe for Water Conveyance Made in China (2024)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

1) Cold / hot water supply facilities for public buildings

2) Food, chemical, electronic industry pipeline networks; Such as Pipeline networks for transporting all kinds of corrosive liquids

3) Drinking water production system pipeline networks; Such as Pure water and mineral water

4) Air conditioning facility pipelines

5) Compressed gas pipeline networks for industry

6) Pipeline networks for swimming pools

7) Pipeline networks for solar energy facilities

8) Agriculture and garden production transporting systems

Application

Distribution for cool and hot water;

Duct for drinkable water system;

Pipes for kinds of high-temperature and low-temperature heating system;

Pipes for heating and cooling settings in solar energy system;

Connecting pipe for air conditioners

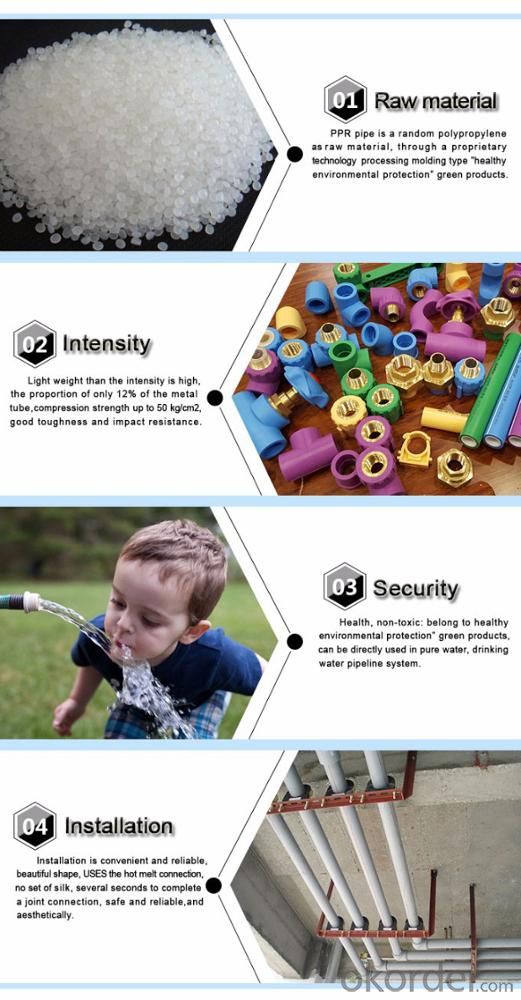

Product Description

Pressure | Size(mm) | Pressure | Size(mm) |

PN1.25MPA | 20*2.0 |

PN1.6MPA | 20*2.3 |

32*2.9 | 32*3.6 | ||

40*3.7 | 40*4.5 | ||

50*4.6 | 50*5.6 | ||

90*8.2 | 90*10.1 | ||

110*10.0 | 110*12.3 |

Shipment/Payment

Packing: 5.8m/11.8m each piece. 50m/100m/150m/200m for small sizes pipes.

Loading port: China port(Chongqing port, Shanghai port, Tianjin port)

Price term we offer: FOB,CIF,CFR

Payment: L/C and T/T

Product Show

Our Services

Pre-Sales Service

1. Inquiry and consulting support.

2. Sample testing support.

After-Sales Service

1. Training how to instal the machine, training how to use the machine.

2. Engineers available to service machinery overseas.

FAQ

When can I get the price?

We usually quote within 24 hours after we get your inquiry. Your inquiry with details will help us to quote you accurate price.

Are you trader company or Manufacturer?

We are comprehensive plastic processing enterprises specializing in the production of PPR pipe, Steel wire reinforced PPR pipe, PPR pipe fittings and welding machines.

What about your payment terms?

Normally T/T or irrevocable L/C at sight.

What about your Free samples?

Samples are available free, all customers shall pay the sample's shipping cost.

What about your MOQ and deliver time?

The MOQ can be discussed. Normally is one container. Normally 3-15 days, if the quantity is big enough, the delivery time will be longer. It is negotiable

- Q: Are plastic pipe fittings suitable for hot water applications?

- Yes, plastic pipe fittings are suitable for hot water applications. They are commonly made from materials such as PVC, CPVC, or PEX, which have high temperature resistance and can withstand the heat of hot water systems. Additionally, plastic pipe fittings are lightweight, easy to install, corrosion-resistant, and cost-effective, making them a popular choice for hot water plumbing projects.

- Q: Do plastic pipe fittings require any special protection against UV exposure?

- Yes, plastic pipe fittings do require special protection against UV exposure. UV rays can cause degradation and weakening of plastic materials over time. To protect against this, it is recommended to use fittings that are made with UV resistant materials or to apply a UV protective coating to the fittings. This will help to extend their lifespan and maintain their structural integrity when exposed to sunlight or other sources of UV radiation.

- Q: Are plastic pipe fittings suitable for swimming pool installations?

- Yes, plastic pipe fittings are suitable for swimming pool installations. They are commonly used due to their durability, resistance to corrosion, and ability to handle the water pressure and chemicals typically found in swimming pools. Additionally, plastic pipe fittings are easy to install and maintain, making them a practical choice for swimming pool plumbing systems.

- Q: Can plastic pipe fittings be used for chemical storage tanks?

- No, plastic pipe fittings cannot be used for chemical storage tanks. Chemical storage tanks require specialized materials that are designed to withstand the corrosive nature of the chemicals being stored. Plastic pipe fittings may not have the necessary chemical resistance and structural integrity to safely contain and store chemicals.

- Q: Can plastic pipe fittings be used in above-ground applications?

- Yes, plastic pipe fittings can be used in above-ground applications. Plastic pipe fittings are versatile and durable, making them suitable for various plumbing and irrigation systems above ground. They are resistant to corrosion, lightweight, and easy to install, making them a popular choice for above-ground applications.

- Q: Water supply and drainage, fire pipeline installation, pipe installation has been included in the quota, if adding the elbow, three links should be the cost of materials, in which the items below?

- If not, the following supplementary material quota and modify the material cost of the corresponding name, unit, quantity, unit price.

- Q: How do you connect plastic pipe fittings to PVC pipes?

- To connect plastic pipe fittings to PVC pipes, you can use solvent cement specifically designed for PVC pipes. First, clean the ends of both the plastic pipe fittings and PVC pipes to ensure they are free from dirt and debris. Then, apply the solvent cement to both the pipe fittings and the pipes. Insert the pipe fittings into the PVC pipes, making sure they are aligned properly. Allow the solvent cement to dry as per the manufacturer's instructions. This will create a secure and watertight connection between the plastic pipe fittings and PVC pipes.

- Q: Are plastic pipe fittings resistant to scale and sediment buildup?

- Yes, plastic pipe fittings are generally resistant to scale and sediment buildup. The smooth inner surface of plastic pipes reduces the likelihood of deposits forming, ensuring long-term functionality and minimizing maintenance requirements.

- Q: Are plastic pipe fittings easy to install?

- Yes, plastic pipe fittings are generally easy to install. They are lightweight, simple to connect, and require minimal tools. Additionally, plastic pipe fittings often feature a push-fit or compression design, making installation quick and hassle-free.

- Q: Are plastic pipe fittings suitable for use in food processing plants?

- No, plastic pipe fittings are not suitable for use in food processing plants as they can leach harmful chemicals into the food, posing a health risk. Stainless steel or other food-grade materials are recommended for such applications.

Send your message to us

Rv Plastic Water Pipe Fittings - User-Friendly PPR Pipe for Water Conveyance Made in China (2024)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches