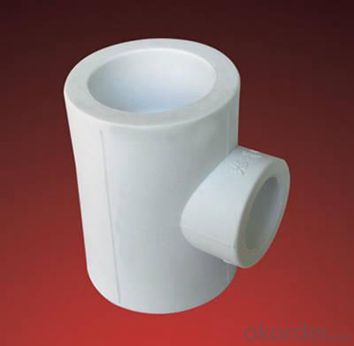

Blue Plastic Water Pipe Fittings - China-Made User-Friendly PPR Pipe for Water Conveyance in 2024

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

1) Cold / hot water supply facilities for public buildings

2) Food, chemical, electronic industry pipeline networks; Such as Pipeline networks for transporting all kinds of corrosive liquids

3) Drinking water production system pipeline networks; Such as Pure water and mineral water

4) Air conditioning facility pipelines

5) Compressed gas pipeline networks for industry

6) Pipeline networks for swimming pools

7) Pipeline networks for solar energy facilities

8) Agriculture and garden production transporting systems

Application

Distribution for cool and hot water;

Duct for drinkable water system;

Pipes for kinds of high-temperature and low-temperature heating system;

Pipes for heating and cooling settings in solar energy system;

Connecting pipe for air conditioners

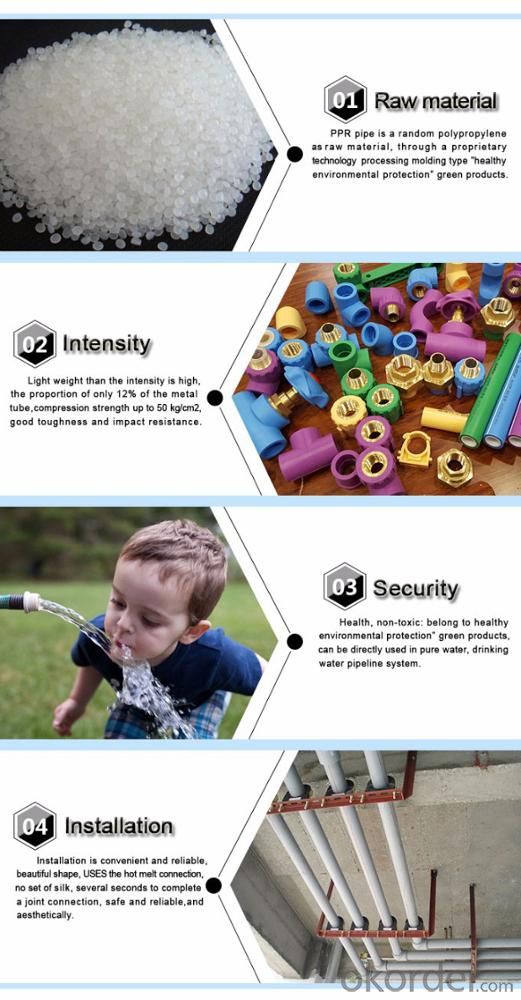

Advantages

1, High Temperature Resistance: the maximum sustained working temperature is up to 70 Degrees Celsius, the maximum transient temperature is up to 95 Degrees Celsius.

2, Heat Preservation: low thermal conductivity which is only 1/1500 of brass pipe, and 1/250 of steel pipe.

Non-toxic: no heavy metal additives would not be covered with dirty or contaminated by bacterium.

3, Corrosion Resistant: resist chemical matters or electron chemical corrosion.

4, Lower Installation Costs: light weight and ease of installation can reduce installation costs by as much as 50% over metal piping system.

5, Higher Flow Capacity: smooth interior walls result in lower pressure loss and higher volume than metal pipes.

6, Long Life: more than 50 years under normal conditions.

7, Recycled and Environment-friendly.

Product Description

Pressure | Size(mm) | Pressure | Size(mm) |

PN1.25MPA | 20*2.0 |

PN1.6MPA | 20*2.3 |

32*2.9 | 32*3.6 | ||

40*3.7 | 40*4.5 | ||

50*4.6 | 50*5.6 | ||

90*8.2 | 90*10.1 | ||

110*10.0 | 110*12.3 |

Shipment/Payment

Packing: 5.8m/11.8m each piece. 50m/100m/150m/200m for small sizes pipes.

Loading port: China port(Chongqing port, Shanghai port, Tianjin port)

Price term we offer: FOB,CIF,CFR

Payment: L/C and T/T

Product Show

FAQ

Q1.Where is your company, factory or trader?

A1.We are Integration of industry and trade which is located in Liaoning Province. China.

Q2.How long is your delivery time ?

A2.Generally it is 5-10 days if the goods are in stock. or it is 20-30 days if the goods are not in stock, it is according to quantity.

Q3. Can I get free samples?

A3: Yes, we can provide you the free samples, but you need to bear their own delivery costs.

Q4. Can I request to change the form of packaging and transportation?

A4: Yes, We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

Q5. How long is your warranty?

A5: Our Warranty is 12 month.

- Q: Can plastic pipe fittings be used for chemical drainage systems?

- Yes, plastic pipe fittings can be used for chemical drainage systems. Plastic materials such as PVC, CPVC, and PE are commonly used in chemical drainage systems due to their resistance to a wide range of chemicals and corrosive substances. These fittings are designed to withstand the demands of chemical drainage and provide a durable and reliable solution for transporting and draining various chemicals.

- Q: How to connect the steel tube and the steel tube?

- Characteristics of electric fusion welding:The electric heating welding technology is easy to construct and quick to implement. It can be used for welding and weldingThe welding reliability is good, and the strength and density are better than other connection methodsKeep the inner wall of the pipe smooth, without affecting the flow area

- Q: How do plastic pipe fittings compare to brass fittings?

- Plastic pipe fittings are generally cheaper and easier to install compared to brass fittings. However, brass fittings are more durable and have a longer lifespan. They are also better suited for high-pressure applications and provide a more secure connection. Ultimately, the choice between plastic and brass fittings depends on the specific requirements of the plumbing system and the budget of the project.

- Q: Can plastic pipe fittings be used for food processing facilities?

- Yes, plastic pipe fittings can be used for food processing facilities. However, it is important to ensure that the plastic used is food-grade and meets all necessary safety regulations and guidelines.

- Q: Are plastic pipe fittings resistant to impact damage?

- Yes, plastic pipe fittings are generally resistant to impact damage. They are designed to withstand common impacts and pressures encountered in plumbing systems. However, the level of resistance may vary depending on the type and quality of the plastic used in the fittings.

- Q: Are plastic pipe fittings resistant to algae and fungi growth?

- Yes, plastic pipe fittings are typically resistant to algae and fungi growth due to their non-porous and smooth surfaces, which inhibit the growth of microorganisms.

- Q: Can plastic pipe fittings be used for chemical storage systems?

- Plastic pipe fittings can be used for chemical storage systems, but it is essential to ensure that the fittings are compatible with the specific chemicals being stored. Choosing chemically resistant materials and considering factors like temperature, pressure, and potential reactions is crucial to maintain the integrity and safety of the storage system. Consulting with experts or referring to chemical compatibility charts can help determine the suitability of plastic pipe fittings for a particular chemical storage application.

- Q: Can plastic pipe fittings be used for dairy processing plants?

- Yes, plastic pipe fittings can be used for dairy processing plants. Plastic pipe fittings are often chosen for their corrosion resistance, durability, and ease of installation. However, it is important to ensure that the plastic used in the fittings is food-grade and complies with industry standards to maintain the quality and safety of the dairy products.

- Q: Plastic pipe connections commonly used in several ways?

- Thread connection, thread connection is more safe and reliable. But because of the thread, the thickness of the pipe and pipe must be thicker than the solvent method and the pipe fittings. Thread packing can be made of white lacquer or raw silk tape.

- Q: Are plastic pipe fittings easy to install?

- Yes, plastic pipe fittings are generally easy to install. They are lightweight, require no special tools, and can be quickly connected using simple techniques like solvent welding, compression fittings, or push-to-connect systems. Additionally, plastic pipe fittings are versatile and can be installed in various plumbing and water supply applications.

Send your message to us

Blue Plastic Water Pipe Fittings - China-Made User-Friendly PPR Pipe for Water Conveyance in 2024

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords