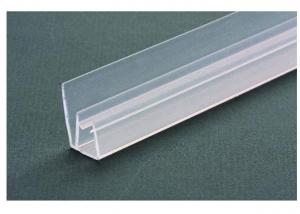

Rubber Washer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 Pieces pc

- Supply Capability:

- 100000 Pieces per Day pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Rubber Washer

ISO9001 and TS16949 factory

Comply to Rohs, FDA, WRAS, NSF

Samples can be ready in 3-7days

Custom molded rubber washers, non-standard rubber washers, we made it according to your drawing.

1. It have 12 CNC machines, 3EDM machines, we can make over 100sets rubber mould per month.

2. Compression/transfer/injection(both hot runner and cold runner are available) types.

3. The common mold steel we use are NAK80, P20, 4140, S50C

4. We have 15years experience in making rubber moulds, especially for rubber molds of electronic rubber parts, automotive rubber parts, toy tires, we are a leading rubber mould maker in China.

5. We have our own rubber products workshop, we can test the mold before ship the mold to customer.

6. We are currently making molds for Japan, Italy, UK, USA, Canada, South Asia companies.

7. Experience sales representative discuss with customer about the mold design prior to mold making.

8. Lead-time, prototype mold in 3-7days, production mold in 1-2weeks, complicated rubber molds like cold runner injection rubber molds in 30days.

Description of Rubber Washer

Material: comply to RoHS, silicone or rubber (NR, SBR, NBR, EPDM, CSM, CR, HNBR, VITON, AFLAS and more)

Hardness: 8 to 95 shore A, tolerance can be ±5 shore A, for some special products, we can reach ±3 shore A tolerance

Color: for rubber, usually black, for silicone, can be in any color as you want

Machine type: 50 to 400 tons

Molding service: we have our own mold workshop which have 12 sets CNC machines and provide compression/transfer/injection rubber molds

ISO9000 and TS16949 certificated factory

Mold/samples lead-time:

For prototype mold, usually in 7days

For mass production mold, usually in 2 weeks

For some special molds, can be in 30days, especially for some automotive rubber molds

Small orders are welcomed

- Q: What does "four items" mean?

- Start the engine at least once a month, idle for 4-5 minutes, check the operation of the engine. In case of abnormal phenomenon, it is necessary to adjust and repair in time. Also, check the battery regularly. The electrolyte level of the battery must be higher than the plate 10-15mm. When it is not enough, the distilled water should be added in time, and the battery should be kept sufficient, and the battery should be charged when necessary.

- Q: General car ordinary car had a puncture can continue to open it, most can run far?

- Hello! You can get a good solution to the problem. At the same time, you are the lady. The tire is stuck and can not be changed! 1. can continue to exercise depends on how you use the tyres, if you use the general tire or ordinary tire, with no gas is not to leave, if you do not remove a puncture of the tire is not discouraged, can exercise to the nearest garage! 2. in order to avoid similar things happen, you can choose anti burst or bullet proof tires, the price may be a little higher, but absolutely not firm, even if the bar will own inflatable, can ensure you successfully reach the destination! But this kind of tires have a common disadvantage is the relatively heavy tire is relatively hard, driving up will feel uncomfortable, but more or less will increase fuel consumption, but also enhance the car's grip, so as to improve the safety factor of the car! Also, after your tire has been inserted, if you make the first supplement, it is recommended to change the tire to the rear wheel, so it will be safer to run at high speed!

- Q: How to remove the silver paint on the black rubber strip and black plastic board?

- Prepare a clean towel, then put the water that day (banana water) poured in the towel to wipe the paint touch up, be careful, don't rub the car paint (up, rubbed paint will wipe flowers) slowly rub, if only glue and glass paint fog method just do what I say, or go to the larger car repair place to see.

- Q: Lianyi auto rubber skid chain, okay?

- But not like you said, only the production of non slip chain chain, the production of anti-skid chain than the same kind of more than two advantages, first, rubber on the improvement, more high, more wear-resistant. Instead, a nylon rope is added to the rubber net to make it stronger and more wearable. More assured.

- Q: Installation method of automobile door glass sealing strip

- This is to go to the 4S shop, the average person is not installed, because the door has radian, there is no specific tool, it is difficult to install. If it doesn't fit, it rains and the water gets in. It's a lot of noise. And you buy the sealing strip, but also the specific thickness of the sheet metal on the door may not be consistent.

- Q: What oil rubber will not deteriorate in the automobile brake pump?

- If the iron powder into the brake pump, so that the internal surface of the sub pump is not smooth, it will easily lead to leakage of oil pump, resulting in sub pump scrapped. It will take time and effort and money.

- Q: What are the rubber parts used in the automotive suspension system?

- Suspension is the floorboard of all the force coupling devices between the frame (or load type body) and the axle (or wheel). Suspension is the role of the various forces acting on the wheel of the pavement and the torque transmitted to the frame (or body type), absorption and ease caused by the uneven pavement driving wheel and frame to beat shock and vibration.

- Q: 3M window lubricant reducer and car seals, maintenance cream which good?

- That drive to the outdoor play friends, try to put the car parked in the sun is not in place, so as to avoid the long time exposure of automotive sealing ring, sealing ring caused a car door, on the edge of the roof deformation and cracking due to heat.It takes care and patience to keep a car. As long as these two points, I believe your car will use longer life.

- Q: Ding Ji rubber and nitrile rubber difference

- Nitrile butadiene rubber is prepared by polymerization of butadiene and acrylonitrile by emulsion polymerization. Nitrile rubber is mainly produced by low temperature emulsion polymerization. It has excellent oil resistance, high wear resistance, good heat resistance and strong adhesive force. Its disadvantages are poor resistance to low temperature, poor ozone resistance, poor electrical properties, and slightly lower elasticity. Nitrile rubber is mainly used in the manufacture of oil resistant rubber products.

- Q: Want to know how the rubber skid on the bus handle is set up?

- It is soft and elastic. Heating (125 degrees) will shrink, widely used in a variety of wiring harness, solder joints, inductors insulation protection, metal pipes, rods rust prevention, corrosion protection.

1. Manufacturer Overview

| Location | Guangdong,China (Mainland) |

| Year Established | 2007 |

| Annual Output Value | |

| Main Markets | Domestic Market Rubber and Plastic Products 61.8 Northern Europe Rubber and Plastic Products 2.7 North America Rubber and Plastic Products 10 Oceania Rubber and Plastic Products 0.9 Eastern Asia Rubber and Plastic Products 5.6 Western Europe Rubber and Plastic Products 19 |

| Company Certifications | ISO 9001-2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Rubber Washer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 Pieces pc

- Supply Capability:

- 100000 Pieces per Day pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords