Rubber Hose for Sand and Grit Blasting Using Nano Technology

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 1000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rubber Hose for Sand and Grit Blasting

The kiynn brand rubber hose for sand and grit blasting is developed after 20 years of extensive studies. Using nano technology, the rubber hose exhibits characteristics of excellent wear-resistance, toughness as well as tolerance towards high pressure, with 3-5 folds wear-resistance of normal sand blast rubber hose and better performance.

Applications:

1. Useful in various kinds of sand and grit blasting machines.

2. In shipbuilding industry, it can be used for removing rust and enhancing adhesion before hull painting.

3. Other industries: Oil tank rust-removing and reinforcing; corrosion protection in gates of bridges and irrigation works; rustproof, de-oxidation, and paint removal for metallic parts.

Main structure:

Inner layer: Using natural rubber, polyurethane rubber and other composite rubbers as major materials, with the addition of special reinforcing agent.

Framework: The fabric reinforced sand blast rubber hose employs fine fabric (canvas) or chemical fabric cloth as reinforce layer; thus having good flexibility and loading-bearing capacity.

Outer layer: Using natural rubber and other composite rubbers, exhibiting good wear- and oxidation- resistance, long useful life and good view.

Main types:

Normal sand blasting rubber hose; rubber hose for waterway desilting, cementing pump truck, concrete, grout, sediment, coal injection truck, bulk cement truck, sandblast, big inch grout hose, white powder and dredging.

Blasting materials:

Quartz sand, steel shot, sediment, ball bearing, cement powder, cement concrete, dry powder mortar, coal fines, carbon powder, and mineral powder.

Suitable temperature: -40°C~+90°C

Technology standard: HG2192-2007

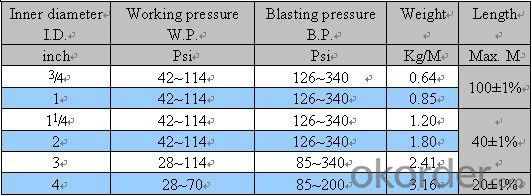

Technology parameters:

Note: 1.The weights above are all theoretical values, and the actual weight needs to be re-determined as the customer’s requirement.

2.Requirements for special working pressure, length, or colors may be satisfied according to orders

- Q: What glue can glue rubber tube?

- Storage: rubber, aluminum alloy, quick drying glue, clean the bottle mouth after use, and screw the lid tightly. After use, please store rubber and plastic glue in a cool and dry place.

- Q: Access toilet water inlet hose joints, how to repair water?

- You try to put the connector aside, hold some force in the toilet hole, or add a person to press it with your hand, then swivel the pipe joint and maybe open it.

- Q: What is the function between the rubber pipe joint and the installing pipe?

- The inner seamless seamless rubber joint prevents the corrosive medium from eroding the inner wall of the rubber joint and improves the service life in the high temperature resistant, acid resistant and oil resistant pipes.

- Q: Classification of metal hoses

- Corrugated metal hose (abbreviated bellow) is a kind of high quality flexible pipe in modern industrial pipeline. The utility model is mainly composed of a corrugated pipe, a net sleeve and a joint. The inner pipe of the utility model is a thin wall stainless steel corrugated pipe with a spiral shape or an annular waveform, and the mesh cover of the outer layer of the corrugated pipe is made of stainless steel wires or steel strips according to certain parameters. The joint or flange at the ends of the hose is matched to the connector or flange of the customer's pipe.

- Q: How do the automobile rubber hoses combine with the quick couplings?

- Turn the rotary handle on the quick connector to the open position first;

- Q: Production process and raw material of rubber

- Process selection: the tensile strength is the limit ability to characterize products can resist tensile failure. The main factors affecting the tensile strength of rubber are: the main valence bond, intermolecular force and polymer chain flexibility of macromolecular chains.

- Q: Carbon dioxide gas shielded welding torch wire feed hose joint, that steel wire can not be drawn out, how to solve it, with welding?

- Replaceable welding wire feeding tube wire feeding tube can be directly removed, if not directly pull out, it may be the welding current and wire melting welding in together, there may be a wire feeding tube after the corrosion resistance increases to pull out, encountered such a situation like a gun only;

- Q: Why are the lengths of the household combustion equipment linked to the gas pipe hose no more than 2 meters?

- Avoid prolonged accumulation of gas combustion

- Q: What are the standard numbers for hose couplings? What standards are they used to accomplish?

- Hose: a tubular rubber product for the delivery of gases, liquids, slurries, or granular materials. It is composed of inner and outer rubber layer and skeleton layer. The material of skeleton layer can be made of cotton fiber, various synthetic fiber, carbon fiber or asbestos, steel wire and so on.

- Q: What kind of material does hose screw protection cover have? What are their advantages and disadvantages?

- Hose cover is usually made of nylon or polyethylene

Send your message to us

Rubber Hose for Sand and Grit Blasting Using Nano Technology

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 1000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords