RP Graphite Electrode with Nipple -300mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Graphite electrode is made from the domestic first petroleum coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc.

The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode.

The range of diameters covers from 200mm to 700mm.

Our products own the following characteristics: low electric resistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanicalshock, high mechanical strength, high machining accuracy.

Graphite Electrodes Features:

RP HP UHP Graphite Electrode

1.Dia:40-600mm or1.6"-24"

2.Length:250-2400mm or10"-96"

3.Nipples:3TPI,4TPI

4.ISO9001:2008

Graphite Electrodes Application:

An increasing proportion of global steel is made using electric arc furnaces, and the electric arc furnace itself is getting more efficient and making more steel per tonne of electrode

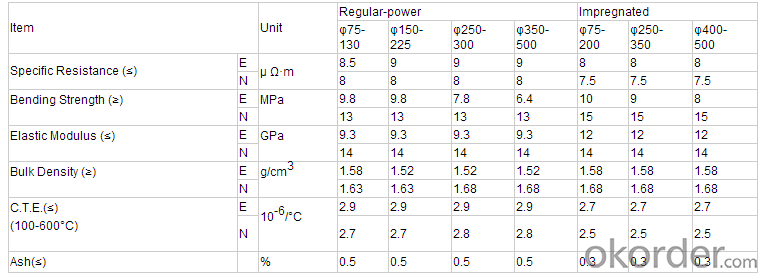

Graphite Electrodes Specifications

Do you know our material of the graphite electrode?

The regular power graphite electrode is made from petroleum coke with a little pitch, which meets

the state standards YB/T4088-2000

The high power graphite electrode is made form 70% petroleum coke and 30% imported needle

coke, which meets the state standards YB/T4089-2000

The ultra high power graphite electrode is made form 100% imported needle coke, which meets

the state standards YB/T 4090-200

Technical data:

Note: The consumption of Electric Arc Furnace(EAF) is about 3-5kg per ton steel. The Ladle Furnace(LF) is about 1kg per ton steel. The converter with Ladle Furnace(LF) is about 0.5kg per ton steel. All the information is for your reference. There are many factors can influence the consumption, such as the kinds of steel, conduction time, process production and so on. So if you have any question, please don’t hesitate to contact us.

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: The future of graphene

- Sensor domain. Graphene due to its unique two-dimensional structure is widely used in sensor, has the advantages of small size, large surface area, high sensitivity, fast response time, fast and easy electron transfer protein immobilization and maintained its activity and other characteristics, can improve the performance of sensor. Mainly used in the production of gas, biological molecules, enzymes and DNA electrochemical sensors. Singapore Nanyang Technology University developed a graphene light sensor sensitivity is 1000 times the ordinary sensor; the Rensselaer Polytechnic Institute developed performance than the existing commercial gas sensor cheap graphene sponge sensor.

- Q: Graphite electrode specifications, graphite electrode manufacturers which good?

- Graphite electrode has good electrical and chemical stability. It has high mechanical strength, low impurity content and good vibration resistance at high temperature. It is a good conductor of heat and electricity. Qingdao Chenyang graphite graphite electrode quality is good, they are a direct manufacturer of graphite electrode. Hope to be of some help to you.

- Q: Specification for graphite electrodes commonly used in steel works

- In general, the graphite electrode used in steelmaking furnace is mostly made of ordinary power and high power graphite electrode. Now, the use of ultra high power graphite electrode increases year by year, accounting for almost half of the graphite electrode.

- Q: Is the anode of electrolytic water suitable for ordinary titanium wires?

- The graphite is cheaper and easier to obtain, but the carbon electrodes sold in the general market are not very pure at most times. The experiment is done for a period of time, and the carbon is inexplicably broken, especially if you need to work for a long time. So, if your graphite electrode is of good quality, it's still graphite.

- Q: Graphite can be used in acid towers in chemical plants because of graphite

- The popularization and use of this technology can bring about such economic and social effects: (1) the consumption of graphite electrode units is less, and the production cost is reduced. For example, a steel plant, according to the annual production level did not occur in LF refining furnace 35 week graphite electrode, refining furnace 165 consumption calculation, using anti oxidation technology of graphite electrode, graphite electrode can save 373 per year(153 tons) electrode, each year ultra high power electrode 16900 yuan computation, can save 2 million 585 thousand and 700 yuan rmb.

- Q: Which department in the steel plant needs graphite in large quantities?

- The variety and specifications of graphite electrodes used in modern EAF steelmaking are mainly determined by the technical parameters of the steelmaking furnace. With the development of EAF steelmaking technology, the steel-making technology is developing towards large scale and ultra high power. The graphite electrode is mainly made of large size graphite electrode and ultra high power graphite electrode.

- Q: What is the application of wire cutting with graphite electrode?

- Machine: wire cutting wire, wire EDM, wire EDM wire is the cutting machine.

- Q: How does graphite produce solar cells?

- In addition, the Research Report of the first author, Massachusetts Institute of Technology Department of materials science and engineering postdoctoral Zhang Shenggen said, different from other semiconductor temperature has been rising continuously, the graphite electrode coating Zinc Oxide nanowires can be temperature controlled at 175 degrees celsius.

- Q: Iron and graphite as electrodes and Nacl as electrolyte solutions. Why do they produce electric current? Graphite and iron react not with solution, can they be connected by wires?

- Because the metal activity order form sodium potassium calcium magnesium aluminum, zinc and tin lead (hydrogen), mercury copper silver platinum, iron in the front row because of water water hydrogen, ionized hydrogen ions by iron replacement

- Q: Can high-purity graphite be used as an electrode?

- The utility model has the advantages of small density and suitable tool electrodes for processing large parts or moulds, and the whole quality is small.

Send your message to us

RP Graphite Electrode with Nipple -300mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords