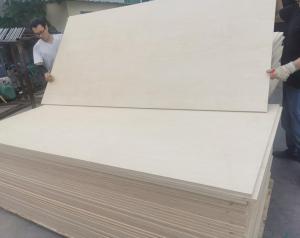

3/4 Plywood Lowes Rotary Maple Face and Back Poplar Core MR Glue

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name: Slice Maple plywood

Face/Back: Maple

Core: Poplar,Hardwood,Pine,Birch,Eucalyptus,Combi etc

Size: 1220×2440mm,1250×2500mm,1220×2150mm,1830×3660mm etc

Thickness: 2.7-30MM

Thickness Tolerance: +-0.1mm~0.3mm <=6mm< span="">

+-0.3mm~0.5mm >6mm

Glue:WBP/MR/MELAMINE/E0/E1/E2

Grade:BB/BB BB/CC CC/CC etc

Moisture: 8-14%

MOQ: 40HQ

Packing Details: 20GP 8pallets/21M3

40GP 16pallets/42M3

40HC 18pallets/53M3

Payment Terms: 30%T/T in advance,70%L/C

Delivery Time: 15 to 20 days after receiving 30%T/T down payments

Grade Description | AA | A | B | C | D | E | ||

Sapwood | No | No | Slight color difference | Slight color difference | Yes | Yes | ||

Heartwood | No | No | No | Slight color difference | Yes | Yes | ||

Color Streaks or Spots | Slight | Slight | Slight color difference | Slight color difference | Yes | Yes | ||

Color Variation | No | No | Slight | Slight | Yes | Yes | ||

Sharp Color Contrasts at Joints | No | No | No | Slight | Yes | Yes | ||

Type of Matching Book Matched Slip Matched Pleasing Matched |

Yes Specify -- |

Yes) Specify -- |

Specify Specify Yes |

-- -- -- |

-- -- -- |

-- -- -- | ||

Nominal Minimum Plain-S Width of Face Quarter 1/4 Componentsa Rotary | 152 mm 76 mm 152 mm | 127 mm 76 mm 127 mm | 76 mm 76 mm 102 mm | No Limit | ||||

Small Conspicuous Burls & Pin Knots-Combined Avg. Numbe | 2 per 1m2

| 4 per 1m2

| 6 per 1m2

| No Limit | ||||

Conspicuous Burls-Max. Size | 6.4 mm | 9.5 mm | 12.7 mm | No Limit | ||||

Conspicuous Pin Knots Avg. Number Max. Size: Dark Part Total |

No |

No |

3 per 3 m2 3.2 mm 6.4 mm | No Limit | ||||

Scattered Sound and Repaired Knots-Combined Avg. Number Max. Size-Sound Max. Size-Repaired Avg. No.-Repaired | No | No |

4 per 3 m2 9.5 mm 3.2mm 4 per 3 m2

|

3 per 1 m2 1 2.7 mm 12.7 mm 4 per 3 m2 |

4 per 1 m2 25.4 mm 19 mm 2 per 1 m2 |

No Limit 38 mm 25.4 mm 1 m2 | ||

Mineral Streaks | No; Maple, Slight | Slight

| Slight

| Slight | Yes | Yes | ||

Bark Pockets | No | No | Few to 3.2mmx25.4mm | Few to 6.4mmx50.8mm |

6.4mmx50.8mm |

Yes | ||

Worm Tracks | No | No | Slight | Slight | Yes | Yes | ||

Vine Marks | Slight | Slight | Slight | Yes | Yes | Yes | ||

Cross Bars | Slight | Slight | Yes | Yes | Yes | Yes | ||

- Q: What does plywood mean and its synthesis?

- Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood, and then made of adhesive glue from the three or more layers of plate-like material

- Q: defects are divided into four grades

- Appearance grade: ordinary plywood according to the processing of plywood can be seen on the material defects

- Q: Now what is the market for plywood development?

- has also been greatly improved in the international market more and more competitive. China is not only a large veneer export, or the world's largest plywood producer.

- Q: Class I resistant weather plywood Class II water resistant plywood

- slab molding (mixing resin and additives pavement), under hot pressure, so that cellulose and Hemicellulose and lignin plasticized to form a plate.

- Q: What are the further processing of plywood?

- Resin Treated Plywood Paste Plywood Plywood with resin impregnated or impregnated with other methods.

- Q: Wood board, plywood, MDF What is the difference

- Can be single-sided sanding, double-sided sanding or both sides are not sanding.

- Q: The Decorative veneer veneer plywood grade classification

- To remind manufacturers and other forms of consumer do not meet the requirements of China's decorative veneer veneer plywood standards

- Q: What is the use of plywood for construction?

- and triclines (commonly known as the three-plate, five per cent, nine per cent, thirteen board)

- Q: Classification of plywood for construction

- if you want to make general indoor wood products, you can use E1 (or even E0) urea formaldehyde

- Q: Plywood quality requirements include appearance level, size, physical and mechanical properties of the three elements.

- Thickness from 4mm below the thin plywood. 3mm, 3.5mm, 4mm thick plywood for common specifications

Send your message to us

3/4 Plywood Lowes Rotary Maple Face and Back Poplar Core MR Glue

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords