3/4 Maple Plywood - Film Faced Plywood with High Quality for Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | Plywoods | Place of Origin: | Shandong China (Mainland) | Brand Name: |

|

| Model Number: | KL | Usage: | Outdoor | Grade: | First-Class |

| Main Material: | hardwood/pine/poplar | Formaldehyde Emission Standards: | E0 | Plywood Type: | Veneer Boards |

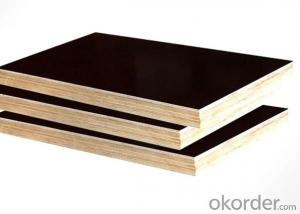

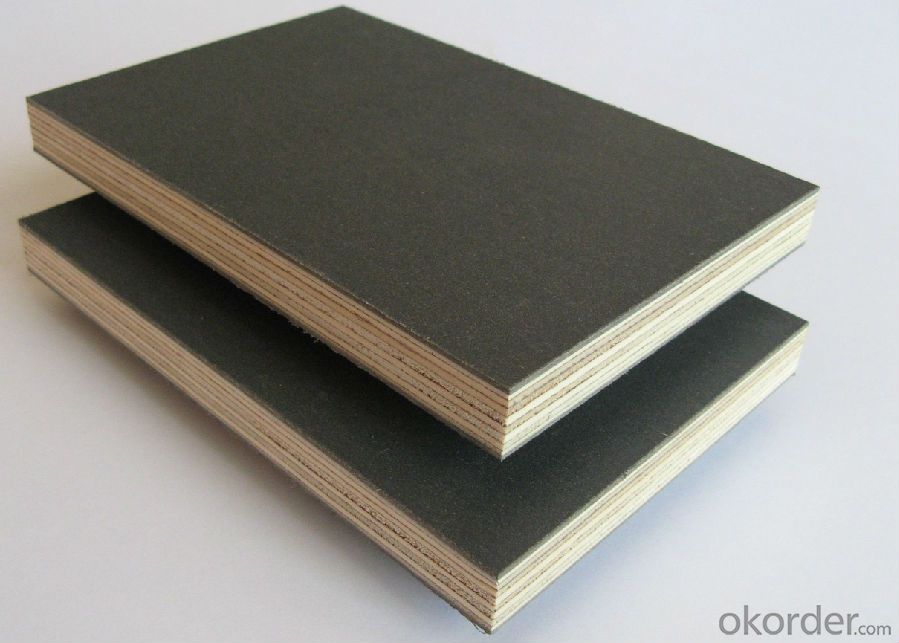

| Veneer Board Surface Finishing: | Double-Sided Decoration | Veneer Board Surface Material: | black/brown/red | core: | hardwood/pine/poplar |

| color: | black/brown/red | size: | 1220*2440*18mm | glue: | WBP |

| Certificate: | American CARB,ISO9001:2000,CE | style: | wbp glue film faced plywood |

Packaging & Delivery

| Packaging Detail: | in pallet |

| Delivery Detail: | within 15 days after received the down payment |

Film faced Plywood Specification

| Product Name | high quality film faced plywood |

| F/B | Black film,Dynea brown film, red film, anti-slip film |

| Grade | AAA grade |

| Core | Poplar, combi, birch |

| Glue | MR glue, Melamine glue, Phenolic glue |

| Thickness | 4mm-21mm |

| Specification | 1220X2440mm, 1250X2500mm,915x1830mm |

| Moisture Content | Under 16% |

| Package | (1) Inner packing: inside pallet is wrapped with a piece of 0.2mm plastic bag (2) Outer Packing: Pallet are covered with 3.0mm package plywood and steel tape for strengthening |

| Certificate | ISO9001:2000 |

| MQQ | 1X40GP |

| Price terms | FOB, CNF, CIF |

| Payment | T/T, 100% irrevocable L/C |

| Delivery time | Within 15 days after receipt of original L/C or 30% deposit |

| Supply Capacity | 50,000 CBM/year |

| Usages: | used for construction/building concrete etc |

| Reuse times | At least 10 times |

| Surface type | :smooth/smooth, smooth/anti-slip |

| Exporting market | Latin America, Europe, Southeast and Middle east area etc |

Production Name

| BLACK/BROWN WATERPROOF FILM FACED PLYWOOD/MARINE PLYWOOD |

Size | 1220x2440mm(4'x8'), 1250x2500mm, 915x1830(3'x6') or as per your requirement |

Thickness | 8-24mm |

Thickness Tolerance | +/-1mm - +/10.5mm |

Number of Plies | From 5 to 15 depending on thickness |

Face/Back | Black Film, Brown Film, Red Film (Film can be printed with requested logo) |

Finish | Glossy, Matt, Anti-slip |

Core | Poplar, Hardwood, Birch, Combined |

Glue | WBP-MELAMINE, WBP-PHENOLIC, MR |

High quality brown film faced plywood Feature

1) High bending strength

2) little linear expansion conefficient

3) Strong nail holding

4) Moistureproof and easy work

5) Tight construction and high strength

6) No ratten or decay

7) Low formaldehyde emission

8) The produces are suitable for the construction of viaduct and tall frame buliding

9) If put in boilding water for 24 hours, it is still glue sticking and nondeformed.

10) If used abide by the illustration strictly, it can be reused more than 30 times

11) Solve the problems of leaking and rough surface during consruction process, particular suitable for watering concrete

Film faced

asily, so good for construction work |

2, Waterproof, Wear-resistant, anti-cracking. |

3, After installation of concrete, the surface looks like a mirror. (The cement does not stick.) |

4, It can be used to make camber and it also can be cut into small pieces according the special requirements. |

5. Environmentally friendly |

6 It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time |

- Q: National standards for decorative veneer veneer plywood performance requirements

- China is the recommended standard GB / T 15104-94 "decorative veneer veneer board", the vast majority of enterprises to implement the implementation of this standard

- Q: The difference between the multilayer board and the plywood is as follows

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences

- Q: How is the current market outlook for plywood?

- Although China plywood has developed rapidly, but still encounter the EU and other importing countries of the anti-dumping complaints

- Q: What is the type of plywood editing?

- the plywood is divided into decorative plywood (for the surface needs to paint transparent paint Furniture, sewing machines and all kinds of electrical appliances and other products)

- Q: What is the use of plywood for construction?

- The outermost front panel is called a panel, the back is called a backplane, and the inner board is called a core plate

- Q: What are the key points for plywood selection?

- panel decoration need to use transparent varnish (also known as oil), to retain the natural color of wood surface and texture, should focus on the panel material, pattern and color selection

- Q: Multilayer board, also known as three plywood and plywood

- usually with odd-level veneer, and the adjacent layer The fiber orientation of the veneer is perpendicular to each other

- Q: What is the difference between plywood glue E0E1?

- Phenolic glue: moisture, excellent resistance to boiling, weather resistance / can be used for outdoor or indoor, can withstand outdoor wind and rain.

- Q: What is medium density fiberboard

- Plywood commonly known as three plywood, five plywood, nine PCT board, twelve PCT board and so on

- Q: Does plywood contain formaldehyde?

- Home plywood is a commonly used material. Plywood is the wood shavings and urea formaldehyde resin pressed together

Send your message to us

3/4 Maple Plywood - Film Faced Plywood with High Quality for Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords