Rock Wool Refractory Ceramic Fiber Cotton (Raw Material)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Ceramic Fiber Cotton( raw material )

Refractory thermal insulation raw materials-ceramic fiber bulk/ceramic fiber cotton/ceramic fiber wool, for raw materials of ceramic fiber blanket, product

Production technology of ceramic fiber cotton

The common ones are made of hard chamotte clay, which are meltdown in resistance furnaces and processed by blowing or swinging technology.

The high purity and high aluminum ones are made of composite materials of pure alumina and silica powder, which are meltdown in resistance furnaces and processed by blowing or swinging technology.

Zirconium ones are made of composite materials of high purity alumina, silica powder and zircon sands, which are meltdown in resistance furnaces and processed by blowing or swinging technology.

Features of ceramic fiber cotton

needled fiber bulk:

Needled ones have long fibre, low ball sediment and low non-fibre material content. The long fiber produced by untreated swinging fibre forming serves as the filling material of wall linings of heaters such as high-temperature furnace as well as the raw materials of textiles due to its good spinnability.

blown fiber bulk:

The untreated fibre produced by blown fiber forming technology with low ball sediment and no lubricants serves as the filling material of high-temperature furnace and the excellent raw materials of vacuum molding products, fibre spraying and fibre paper.

Typical Application of ceramic fiber bulk

Raw materials of fiber Paper and vacuum forming products

Raw materials of fiber coating materials;

Raw materials of fiber castable and coatings;

High-temperature furnace heating equipment wall lining fillings

Raw materials of fiber textile products

Technical Data of ceramic fiber cotton

Type | Common | Standard | High Purity | High-aluminium | Zirconium | |

Classification temperature (°C) | 1100 | 1260 | 1260 | 1360 | 1430 | |

Working Temperature (°C) | <1000< span=""> | 1050 | 1100 | 1200 | 1350 | |

Color | white | white | white | white | white | |

Fiber diameter (um) | Blown | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 |

Needled | 3-4.5 | 3-4.5 | 3-4.5 | 3-4.0 | 3-4.0 | |

Chemical composition | AL2O3 | 44 | 46 | 47-49 | 52-55 | 39-40 |

AL2O3+SIO2 | 96 | 96 | 99 | 99 | - | |

AL2O3+SIO2+ZrO2 | - | - | - | - | 99 | |

ZrO2 | - | - | - | - | 15-17 | |

Fe2O3 | <1.2< span=""> | <1.0< span=""> | 0.2 | 0.2 | 0.2 | |

Na2O+K2O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 | |

Remarks: The data above is for reference. The Max. temperature depends on the using conditions.

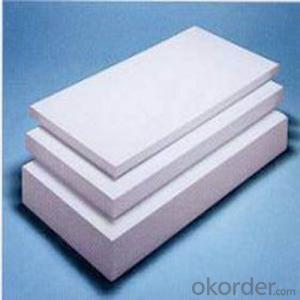

- Q: What does the rock wool board look like?

- June 1981 test success Rock wool board is a new type of insulation, fire, sound absorption material.

- Q: What role does dolomite play in rock wool products?

- Pu hard foam layer can be firmly bonded with the base layer, the adhesive strength can exceed the tear strength of the foam itself, so Pu hard foam and the formation of the base layer, easy to delamination, to avoid the water along the interlayer

- Q: Rock wool products are divided into several categories

- In the rock wool by adding special adhesive can be processed into rock wool board, rock wool stave, rock wool insulation and other products, as the building insulation, insulation, cold, sound-absorbing material

- Q: How to judge the quality of rock wool

- How to judge the quality of rock wool

- Q: The difference between rock wool and rock wool

- Yanmian tube with high strength and good flexibility, with a certain pressure, the pleated treatment of rock wool tube with a large drawing strength, not easy to layer, greatly improving the durability of the durability

- Q: Rock wool products and aluminum silicate acupuncture blankets are same

- No, rock wool is ore blown wire, aluminum silicate is coke gem

- Q: Rock wool insulation material fire rating is how much

- With low thermal conductivity, the use of high temperature, fire non-flammable, construction convenience, energy-saving effect is remarkable, there is a high cost performance. Adiabatic with rock wool, mineral wool and its products for a variety of pipe insulation and fire protection

- Q: Rock wool board is inorganic composite insulation material

- Rock wool products are inorganic insulation materials

Send your message to us

Rock Wool Refractory Ceramic Fiber Cotton (Raw Material)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords