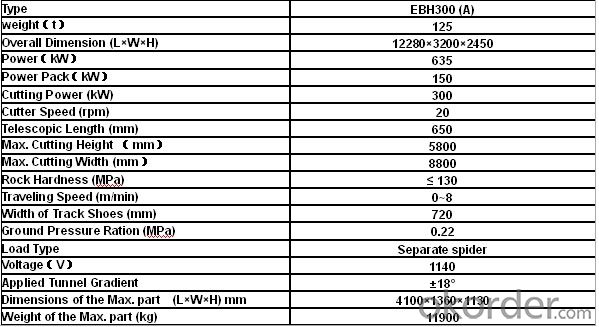

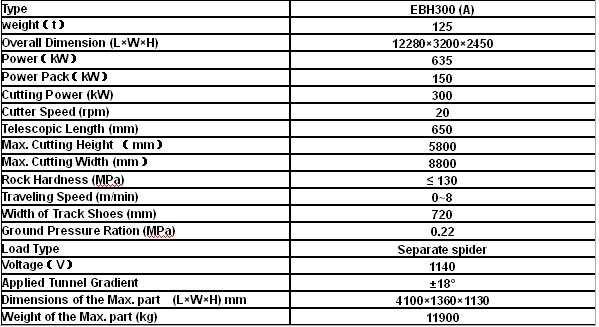

Rock Tunnel Boring Machine EBH300(A) good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 100 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EBH300(A) Rock Tunnel Boring Machine

Applications: for the tunneling of rock and semi-rock roadway, also used in the tunneling of highway, railway, and water conservancy projects. The cutting hardness is ≤13

Features:

1. Computer controlled, wireless remote-controlled, intelligent forming cutting and constant power cutting.

2. 125 tons weight to guarantee the stability and power during cutting.

3. Advanced centralized lubricating system to guarantee the reliability of every parts

4. High-efficient separate motor for loading and transporting, more suitable for rock roadway heading.

5. New design of apron, the first class of cutting pick and pick base to guarantee the rock cutting capacity.

- Q: The equipment of our unit needs to be cleaned regularly, oil pollution is very much, every time manual washing efficiency is too low, what method can be solved quickly?

- Normally use a sponge to absorb it, and then paste it with the dough. The equipment is special, and the larger tank is recommended to be manually and relatively clean. The small fuel tank recommended washing during operation and increasing the filter frequency. The best solution is to find the source of the oil, such as external dust pollution, internal wear and tear, and the quality of oil, which is solved by the root cause.

- Q: What are the types of cleaning equipment

- That is too much There are all kinds of homes, there are all kinds of business, and there are all kinds of special things

- Q: What is the issue of cleaning equipment? Is there a difference between industrial cleaning equipment and common equipment?

- Nonsense. Working in the hardware factory, facing the machine all day long, our company's xinxin promised the GCL equipment, the operation is ok, we heard that it is rented. The rent for 20,000 yuan per month

- Q: What should I consider? To solve the

- Cleaning equipment at present, a lot of international medical devices by using ion exchange, reverse osmosis and ion exchange group legal and reverse osmosis and EDI combination preparation of medical apparatus and instruments clean water, the water treatment equipment manufacturers aimed at the development of medical cleaning equipment market space, are put into research and development industry. According to the process of the preparation of ultra-pure water, there must be an advantage in the development of devices.

- Q: How often do the reverse osmosis of pure water equipment wash the search?

- Generally 3 ~ 12 months clean, if every month had to be cleaned once, this explanation should improve the pretreatment system, adjust the running parameter. If you need to clean it once or three months, you will need to improve the operating level of the equipment, and it is difficult to determine if you need to improve the pretreatment system.

- Q: Where can I buy cleaning equipment

- Taobao, ali has a lot of, but the preparation factory actually is a few, the basic of taobao is the trafficker... If you haven't done it, try not to buy it, the depth of the device, it's too easy to get into a pit, find a physical store to practice, and see what they're using to buy the best

- Q: Is it ok to clean the car with a dry ice cleaner?

- Sure! But dry ice machine to clean is wasted, because most of the dry ice machine is cleaning the car at the bottom of the tank or car, car cleaning is commonly used water cannons and vacuuming suction machine, conditional a steam cleaner to wash the car for the internal high temperature disinfection

- Q: What cleaning equipment does the factory clean equipment need?

- A, plant, Workshop area mainly include workshop and warehouse, the characteristics of the environment is that difficult to clean and dirty, the area is large, the environment need to be efficient driving type washing machine, charge can clean the tens of thousands of square meters area, effectively improve the level of clean. Second, office space The office area usually is laid carpet according to need, so general can not use the ground machine. We need to use a vacuum cleaner for the daily cleaning of the carpet, and if we are not careful with the carpet, we need to use the suction machine. Carpet in the middle of care we need to use dry foam carpet cleaning machine, foam carpet cleaning machines and carpet washing machine and spray carpet smoking machine equipment, such as carpet of general and one month to do a thoroughly clean, can effectively remove dirt. When the carpet is cleaned in the long run, it is difficult to clean thoroughly in the middle and late stage, and then you need to use a carpet washing machine. The carpet washing machine can be used in the middle and later of the carpet to clean the carpet effectively, can make carpet the refurbishment work, the surprise that can surprise unexpectedly! Outdoor squares and open Spaces These places usually area is large, open, open, although it is difficult to clean, but not general cleaning requirements is very high, you just need to keep the floor clean. We recommend sweeping machines to remove dirt and dirt from the ground and keep it clean.

- Q: What are the methods of general cleaning of mechanical equipment?

- As long as you want to water Gasoline, diesel cleaning, cleaning agent

- Q: It is best to wash mechanical equipment using that cleaner

- See what equipment needs to be cleaned, the current cleaning agent is nutritionally ionized, non-ionized... Principle: 1. The cleaning agent shall not be related to damage, corrosion and pollution. Effectively remove dirt; You can satisfy these two principles

Send your message to us

Rock Tunnel Boring Machine EBH300(A) good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 100 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches