Road Geotextile HDPE Geomembrane for Aquaponics Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

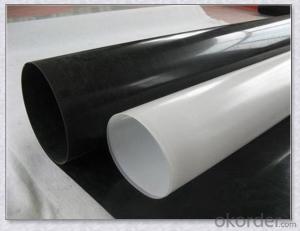

Impermeable Geomembrane HDPE for Shrimp Pond is mainly made of virgin HDPE with blow molding technique. Its main function is to prevent the liquid leakage and gas volatilization.

Application

1. Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2. Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3. Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4 .Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5. Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6 Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.)

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Geotextile what is the law?

- Geotextiles, engineering cloth, impermeable cloth, non-woven fabrics, polyester cloth, health cloth, permeable cloth, etc., which are based on the use of different materials or different materials. But in fact are geotextiles. Geotextile types are many: woven geotextile, staple acupuncture geotextile, filament geotextile, impervious geotextile, non-woven geotextile, composite geotextile, warp-resistant geotextile

- Q: What are the different geotextile filtration testing methods?

- There are several different geotextile filtration testing methods, including the gradient ratio test, the constant head test, the falling head test, and the sand column test. These tests are conducted to evaluate the ability of geotextiles to filter out fine particles from water or other fluids, and to assess their performance in various filtration applications.

- Q: How do geotextiles contribute to land reclamation in coastal areas?

- Geotextiles contribute to land reclamation in coastal areas by acting as a barrier between the existing soil and the new land area. They help prevent erosion by stabilizing the soil, allowing vegetation to grow, and providing a foundation for the new land. Additionally, geotextiles can filter sediment and contaminants, improving water quality and protecting the surrounding ecosystem.

- Q: Hope expert expert to give the answer

- The ditch is the ditch at the edge of the roadbed, mainly used to collect and exclude a small amount of surface water within the roadbed and flow to the roadbed; drainage ditch is the ditch, cut ditch, roadbed near the water discharged to the bridge or road Where the ditch in the natural river ditch. Geotextile is a kind of synthetic high strength fiber material which is used to improve the bearing capacity of subgrade when the bearing capacity of the foundation is poor. It has many kinds of fiber materials. The purpose is to improve the bearing capacity and prevent the cracks in the road surface.

- Q: Textile geotextile lap length how much

- Lap width is generally 10-15cm

- Q: How to build a good 12 by 24 brick wall

- Sand can not be thick, cement: sand that is 1: 4 plus a small amount of lime. If the brick is an excellent product. The number of piers. Masonry technology is excellent. Construction according to construction specifications. The length of the stubble stubble, the vertical and horizontal successively and rationally.

- Q: How do geotextiles help with filtration in wastewater treatment systems?

- Geotextiles serve as a crucial component in wastewater treatment systems by providing effective filtration. These specialized fabrics have excellent permeability, allowing water to pass through while retaining solid particles and contaminants. Geotextiles act as a physical barrier, preventing the clogging of drainage systems and ensuring efficient flow of water through the treatment process. They also assist in the separation and retention of suspended solids, which aids in the removal of pollutants, sediments, and organic matter from wastewater. Overall, geotextiles enhance the filtration capacity of wastewater treatment systems, leading to improved water quality and environmental sustainability.

- Q: Can geotextiles be used in erosion control blankets?

- Yes, geotextiles can be used in erosion control blankets. Geotextiles are often used as a material in erosion control blankets to provide stabilization and reinforcement against soil erosion. They help to prevent sediment runoff and promote vegetation growth, making them effective in erosion control applications.

- Q: What is the price of composite geotextile?

- Geotextile is divided into polyester short geotextile, staple acupuncture geotextile, polyester filament geotextile, woven geotextile, filament woven geotextile, and so on. Specifications and different models, the price is also different, composite geotextile weight in the 80-1500g / ㎡ between the quality standards are divided into non-standard, whitening A, Sinochem, the general national standard and so on. The t value is generally between 4900 and 7500 yuan / ton, 187 & lt; 6600 & lt; 5604

- Q: 3923.1 why not apply to geotextiles

- Geotextile price, geomembrane price, composite geomembrane price can be found tgcl1123 to see

Send your message to us

Road Geotextile HDPE Geomembrane for Aquaponics Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords