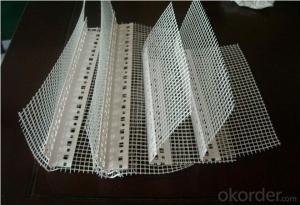

Reinforced Fiberglass Mesh Corner Bead, 75-160g/m2, 6x6/inch, High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Quick Details of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality

MOQ of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality: 5000 Square Meters

Supply Ability of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality 6000000 Square Meters per Month

Payment Terms of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality: L/C,T/T

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality

Specifications of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality Place of Origin: China (Mainland)

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality Brand Name: CMAX

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality Application: Wall Materials

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality Width: 1M-2M

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality Size: 6*6/ INCH

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality Weight: 40gsm to 200gsm

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality Weave Type: Plain Woven

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality Yarn Type: C-Glass

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality Alkali Content: Medium

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality Standing Temperature: 500℃

Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality

Product information of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality

Name: Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality

Use best fiberglass yarn and best glue

Clear and beautiful Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality

High strength Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality

30 years experience of manufacturing Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality

Excellent Priced

FAQ of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality

Q: What is Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality?

Coated Alkali-resistant Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the specification of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality?

Weight: 90-160g Width: 0.2M--2M

Length: 20m, 50m, 100m

Q: What is the application of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality?

PVC corner Bead using

Q: What is the storage of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality?

Four years under normal weather conditions and use .

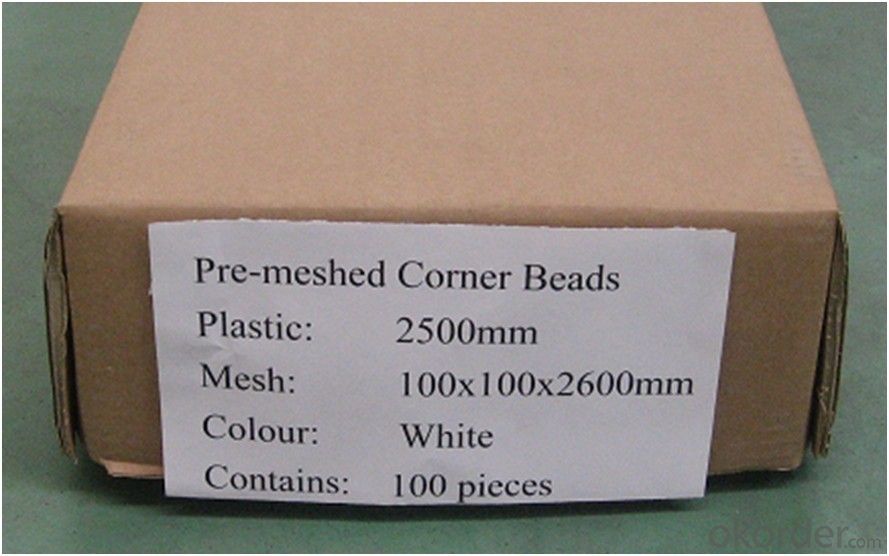

Q: What is the package of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality?

Package: rolls are packed into cartons or pallets.

Packing volumes: 30000m2/40HQ.

Q: Wow long about the production periods of Corner Bead Mesh, 75-160g/m2, 6X6/inch, High quality?

Production periods: 30days for 1X40HQ.

- Q: Does the new house wall need to paste mesh?

- Pasting mesh is based on your walls, if the wall cracking too much, it is recommendated to paste mesh in the whole wall; if it is less, you just need to paste at the cracking place.

- Q: When does aerated concrete block wall need to be pasted with fiberglass mesh?

- When it is for polystyrene?board external wall thermal insulation.

- Q: What is the difference between different glass fiber mesh cloth

- A general glass fiber mesh cloth roll at both ends, both ends of blue green is non alkali glass fiber products

- Q: With regard to the wall cracking treatment, decration team recommends to fully paste mesh.

- Eradicate the original wall, use strengthening agent to seal base, then levle out with formaldehyde, and brush gypsum-based paint fully.

- Q: Can the internal wall plastering be made of fiberglass mesh? The wire mesh is in contact with each other

- The interior wall is usually made of paint, so it is OK to use fiberglass mesh for the anti cracking net.

- Q: Screen window mesh is good stainless steel or glass fiber material?

- Because of its acid, alkali and cold resistance, glass fiber has high adaptability to harsh environment.

- Q: Interior wall laying fiber mesh cloth, what matters should pay attention to plastering? Is it not allowed to lap when laying mesh cloth?

- Before construction, do a good job of watering walls, wet and beat, the fiber network overlap of not less than 100mm, the corner of the door should be laid, so that the grid is not exposed.

- Q: As for the latitudinal tension and longitudinal tension of alkali resistant glass fiber gridding cloth, which is larger?

- latitudinal

- Q: What is the specification of external wall thermal insulation mesh

- external wall thermal insulation mesh 1, interior wall thermal insulation mesh specifications: Mesh size: 5x5mm, 4x4mm gram weight: 80g165g / m2 Width: 1000mm2000mm length: 50m300m 2, external wall thermal insulation mesh specifications: Mesh size: 5x5mm, 4x4mm gram weight: 80g160g / m2 Width: 1000mm2000mm length: 50m, 100m or 200m Color: White (standard), blue, green or other colors Packing: According to customer requirements 3, GRC enhanced mesh product specifications: Mesh size: 8x8mm, 10x10mm, 12x12mm gram weight: About 125g / m2 width: 600mm, 900mm, 1000mm length: 50m or 100m Color: White (standard), yellow, green or other colors Packing: According to customer requirements 4, glass?fiber tape specifications: Specification: 8x8mm, 9x9mm gram weight: 55g85g / m2 Width: 25mm - 1000mm length: 10m150m Color: It is usually white mesh is the indispensable material in the vast majority of insulation materials, including rivet and various mortar.

- Q: What is the purposes of epoxy resin mesh?

- Epoxy resin mesh is widely used in casting dry-type transformer coils and reactor coils with filler, which mainly uesed in the inner and outer cladding and layer insulation. It is connected closely with epoxy resin of casting coils to reinforce anti-cracking performance of casting coil. The function of mesh is same to the rebar of concrete, which can prevent cracking at the coil insulation layer due to the effect of hot and cold and huge electric power caused by sudden coil short circuit, greatly improving the overall mechanical coil strength. The mesh for inter-layer insulation of coils is a major insulation between the layers, which can improve the thoroughness and integration of resin casting, and prevent the coil internal faults and cracks, improved insulation and mechanical strength of the coil

Send your message to us

Reinforced Fiberglass Mesh Corner Bead, 75-160g/m2, 6x6/inch, High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords