Ceramic Fiber Board for Furnace Chamber

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fiber Board for Fireplace 1260C

Product Description

General Information

Characteristic of heat resistant insulation board

1.High crushing strength, long service life

2.Low thermal capacity, low thermal conductivity

3.No brittle material, good toughness

4.Size precision and good flatness

5.Easily cut installation, construction is convenient

6.Excellent resistance to wind erosion performance

7.Continuous production, uniform fiber distribution, stable performance

Application:

1 All kinds of industrial furnace hot face and back face insulation

2 Kiln linerof the high-temperature furnace, kiln cars, door damper, furnace temperature to separate plate

3 Deep processing products molding mould, like Craft glass etc

4 Astronavigation,Shipbuilding heat insulation,fireproofing, sound proofing, insulation.

CERAMIC FIBER BOARD ---STD

Classification Temperature (℃) | 1260 |

Working Temperature (℃ ) | 10 00 |

Color | White |

Bulk Density (kg/m3 ) | 240-300 |

Thermal Conductivity(W/m.k) | |

400℃ | 0.067 |

600 ℃ | 0.094 |

800 ℃ | 0.136 |

1000 ℃ | 0.152 |

1200 ℃ | 0.190 |

1300 ℃ | - |

Thermal Shrinkage 24hrs (%) | 1200℃ |

-3.3 | |

Chemical Composition (%) | |

Al2O3 | 45-47 |

Al2O3+ SiO2 | 97-98.5 |

Note: Technical Data are typical results from test pieces. This information, subject to change, is offered solely for your consideration. Users of our products should make their own tests to determine the suitability of each product for their particular purposes.

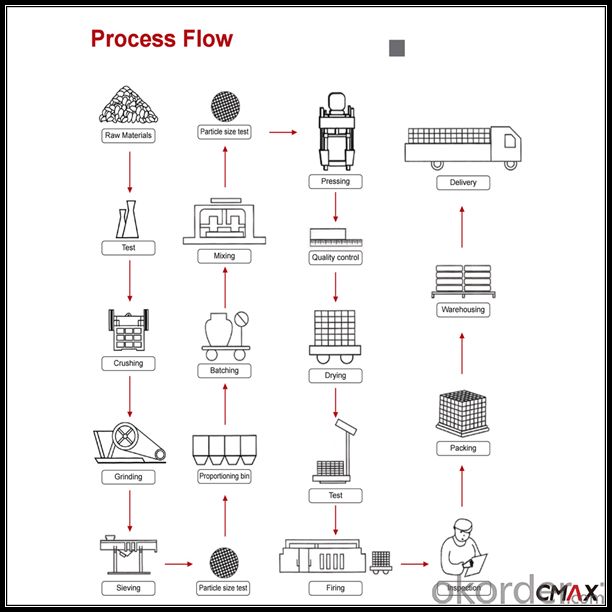

Ceramic Fiber Board Process Flow

Packaging & Shipping

Packaging Details: Wrapped by plastic bag and then put into carton box designed for export.

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron&steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research,development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection,supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Company Information

CNBM (China National Building Material) Group is the largest comprehesnsive building materials group in China that in intergrate scientific research,manufacturing and logistics into one entity.the largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields,CNBM is playing the leading role in the building industry in the country.

FAQ

1.Are you a manufacturer or trader?

Factory + trade (mainly factories, at the same time, we operates other related products)

2.Can we visit your factory?

Sure, welcome at any time, seeing is believing

3.What's the MOQ of trial order ?

No limit, We can offer the best suggestions and solutions according to your condition.

4.Which payment terms are you accept?

T/T, LC, Western Union, MoneyGram, Paypal are available for us.

5.After an order is placed, when to deliver?

15-45days

6.Is your company accept customization?

We have own factory and excellent technical team, and we accept OEM service.

- Q: What method should be used to measure the thermal conductivity of fiberboard?

- It is concluded that the test error of this method and device is about 2%. This filament ultra light aluminum silicate fiber product: the filament ultra light aluminum silicate product is by Shandong Zibo high quality burnt precious stone as raw material, passes through the smelting furnace, the rejection silk, blows the cotton, the auxiliary mold and so on to deliver the work procedure. Therefore, the thermal conductivity of fiberboard is chosen by heat flow meter method.

- Q: What are the standards for ceramic fiber boards?

- Ceramic fiber board is made of continuous production, water production line and advanced technology, ceramic fiber board produced with smooth surface, accurate size, good toughness, can be arbitrarily cut, good insulation effect and other performance characteristics.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber board is of high quality ceramic fiber cotton with low slag ball content as raw material, using specific pulp and mixing equipment, ensure the cutting length and the concentration uniformity of cotton fiber, using international advanced vacuum molding technology and international advanced processing technology, the product not only has excellent mechanical strength and precise geometry the size, and maintains the excellent properties of fibrous insulation materials, can be substituted for calcium silicate board also requires tough, self-supporting and refractory insulation field.

- Q: Refractory insulation board, pressure plate, nano heat transfer plate, calcium silicate board and ceramic fiber board, which is good?

- Ceramic fiber boardCeramic fiber board product categories:1260 standard ceramic fiber board sygx-264 1260 high purity ceramic fiber board sygx-3641400 zirconium ceramic fiber board sygx-564 1400 high alumina ceramic fiber fire plate sygx-464D1400 zirconium ceramic fiber fire baffle sygx-564D

- Q: What are the sound-absorbing fiber boards?

- Sound-absorbing material:1, itself has sound-absorbing properties, porous fiber material.2, does not have sound-absorbing material, but processed into sound absorption structure.Common sound-absorbing materials are: polyester fiber sound-absorbing board, trough wood sound absorption board, hole wood sound-absorbing board, recycled wood sound-absorbing board, the latest is Dr. sound, high temperature ceramic sound-absorbing board, a fire prevention, water quality, hard environmental protection

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The nano ceramic fiber board through the introduction of nanotechnology, the special production process, product performance has been greatly improved, high strength, low thermal conductivity, good heat insulation performance, energy saving effect is obvious, which improves the safety of the furnace, and in high temperature and high pressure conditions, can also play a good performance the product.

- Q: What are the specifications of the ceramic fiber board?

- Ceramic fiber board common specifications are: 600*400, 900*600, 1000*600 and 1000*1200mm, thickness 10/20/25/30/40/50mm, thinnest can do 6mm.Depending on the temperature range, it can be divided into:Common ceramic fiber board HLGX-164Standard ceramic fiber board HLGX-264High purity ceramic fiber board HLGX-364High alumina ceramic fiber board HLGX-464Ceramic fiber board containing zirconium HLGX-564

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- Nano ceramic plate for ceramic fiber with insulating board (felt), it is a functional material with excellent properties of aerogel insulation material and has a heat shielding function, adaptation to adhesive and a variety of inorganic elements in high temperature ceramic fiber as reinforcing material, through a special process preparation.

- Q: What are the uses of ceramic fiber boards?

- Ceramic fiber board is the main use of heat insulation, fire protection, insulation to use, but also with sound absorption, noise reduction, thermal shock resistance and so on. Ceramic fiber board is mainly used in all kinds of furnace lining insulation, kiln wall lining insulation, metallurgical industry furnace fire, aluminum reduction tank, refractory brick backing.

- Q: Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- 1, high compressive strength, long service life; 2, low heat capacity, low thermal conductivity;3, non brittle material, good toughness;4, accurate size, good flatness;5 、 easy to cut and install, easy to construct;6, excellent wind erosion resistance;7 、 continuous production, uniform distribution of fiber, stable performance.

Send your message to us

Ceramic Fiber Board for Furnace Chamber

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords