recycled Polypropylene Staple Fiber for Geotextile or Toys

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

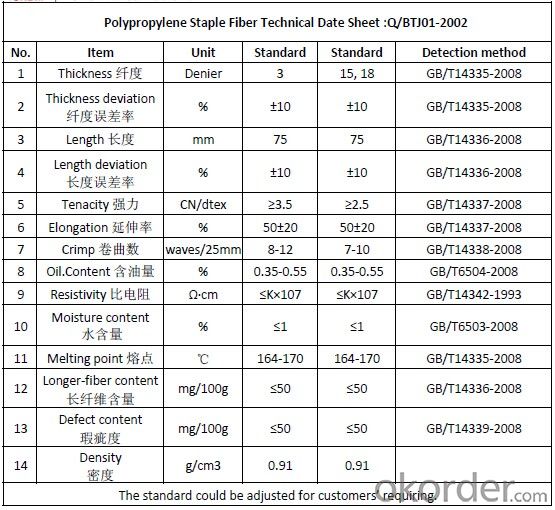

1, PP Staple Fiber

PP staple fiber is characterized with high tenacity and antiflaming, anti-aging,anti-UV,water-repellency can be added to improve its performance.

Specification: 1.5D-110D, 5-150MM. Regular specification includes 3D,4.5D,6D,18D,38MM, 65MM,76MM,102MM etc.

Color: white, black, red, green etc, as per customers requirements.

2, Package of PP Staple fiber

250KG OR 300KG Per bale, wrapped by PP fabric and about 75 bales could be put into 1x40'HQ, allowing more or less clause.

3, Specialities of PP Staple Fiber for Oil Absorption Felt

A:not absorb water

B:acid resistant and alkali resistant

4, Application of PP Staple fiber

A:Geotextile, filing material for toys

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of PP staple fiber which is used as the raw material of textile, automotive interior etc. We have exported this product to Amereica, Europe and South East Asia. Customized product is also available based on your detailed requirements.

2> What's the MOQ ?

We kindly recommend 1x40'HQ as the price would be economical based on large loading quantity.

3>How long can we receive the product after purchase?

It takes about 1 to 2 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q: How do you recognize the wool of a sweater?

- First of all, the texture of the wool fabricWool, rabbit hair, camel hair, wool type chemical fiber as the main raw material of the fabric, usually with wool for the living, it is the year of high-grade fabric, good elasticity, anti wrinkle, stiff, durable wear-resistant, strong warm, comfortable and beautiful, pure color and other advantages, the price is also the most expensiveBut now there are a lot of chemical fiber fabric sweater, with its fastness, good elasticity, stiffness, abrasion resistant washing, easy storage and loved by the people. Purified fabrics are fabrics made from pure chemical fibers. Its properties are determined by the properties of the chemical fibres themselves. Chemical fiber can be processed according to different requirements into a certain length, and woven into imitation silk, Imitation cotton, imitation linen, elastic imitation wool, medium length imitation wool fabric according to different requirements, and its price is also the cheapest

- Q: The towel / towel in the bamboo fiber is getting stiff. How do you get back to the original softness?

- This phenomenon, to harden the towel back and forth with the hand rub, and then wash it with softener, remember, bamboo fiber towel is not easy ripping, not for a long time to soak in the water, drying time, choose a ventilated place on the line, not easy to long time direct sunlight

- Q: Does chemical fiber belong to polyester fiber?

- Any of various fibers made from natural or synthetic polymers as raw materials and processed by chemical or physical methods. Because of the different sources of polymers used, they can be divided into artificial fibers made from natural high polymer materials and synthetic fibers using synthetic polymers as raw materials. Chemical fiber. Polyester fiber belongs to chemical fiber, not chemical fiber, it belongs to polyester fiber. Polyester fiber belongs to staple fiber. Please adopt.

- Q: What do you mean by "T300 T700" in carbon fiber?

- Carbon fiber (carbon fiber, referred to as CF) is a new kind of fiber material with high strength and high modulus fiber with carbon content of more than 95%.

- Q: Can the mask made of high electrostatic fiber be washable?

- After dust is captured by superfine electrostatic fiber cloth, it is difficult to be washed away, and the water washing will also destroy the electrostatic dust absorption ability. Therefore, the non-woven fabric respirator can not be cleaned, and it needs to be discarded after use.

- Q: Polyester and polyester fabrics are good

- Polyester fiber (polyester fibre) synthetic fiber polyester fabric is composed of organic acid and diol which is prepared by spinning the. Polyester chain research report pointed out: industrialization, a large number of polyester fiber is made from polyethylene terephthalate, China's product called polyester.

- Q: What is the viscose chemical or natural? Will the ball?

- When we examine textiles, we have pilling tests. Basically all the textile materials are pilling, but the pilling is easy.

- Q: What is the environmental protection rating of MDF?

- The density board has smooth surface, fine material, stable performance, firm edge and good decoration on the surface of the board. But the density board is poor in moisture resistance, and compared with the density board, the nail holding capacity is worse than that of particleboard. If the screw is tightened, it will be difficult to fix because of the low strength of the density board.

- Q: Nine plate and MDF specific differences, their respective uses?

- Mainly used to strengthen wood flooring, door panels, partitions, furniture and so on. MDF is mainly used for surface treatment of blending process in home decoration.

- Q: How are invisible absorbing materials made? What is the carbon fiber method?

- If the paint is used unilaterally, it may begin with less shells. This point, in erosion resistance, cold pile embedding technology used by predecessors, and so on, the effect is very general. Similarly, when the plane is flying, the air pressure is very frictional, and part of the place is hot. Unilateral use of paint is prone to flaking.

Send your message to us

recycled Polypropylene Staple Fiber for Geotextile or Toys

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords