Rectangular Steel Pipe Production Serious

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Rectangular Steel Pipe Production API A106:

Rectangular Steel Pipe Production is formed by drawing a solid billet over a piercing rod to create the hollow shell. And what we provide you is good quality production, and what we want is far cooperation and not only in one time.

2、Main Features of the Rectangular Steel Pipe Production API A106:

• High manufacturing accuracy

• Very small inertia resistance

• Powerful heat dissipation ability

• Good visual effect

• Reasonable price

3、Rectangular Steel Pipe Production API A106 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Rectangular Steel Pipe Production API A106:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.We company professional to provide these serious of pipes and what we can give you is not only in good sprice, the most important is we can provide you good quality.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one, and we always to provide you discount, we are trying to give every customer best price and satisfy price.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

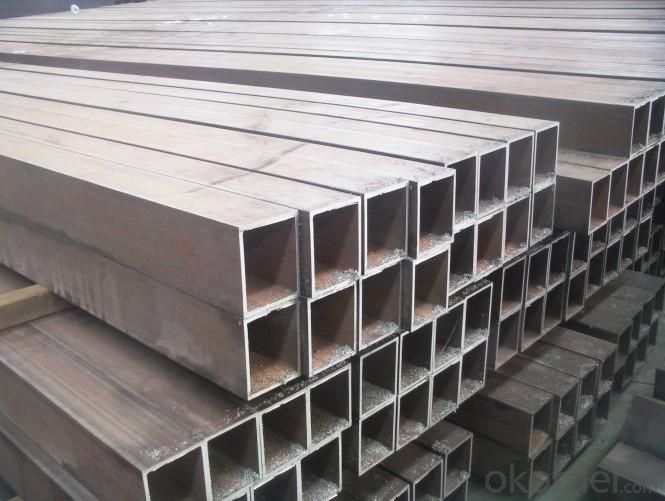

6、Rectangular Steel Pipe Production API A106 Images:

- Q: Can steel pipes be used for both high-pressure and low-pressure systems?

- Yes, steel pipes can be used for both high-pressure and low-pressure systems. Steel pipes are known for their strength and durability, making them suitable for various applications. They are capable of withstanding high pressures without deformation or leakage, while also being reliable for low-pressure systems.

- Q: How do steel pipes perform in extreme weather conditions?

- Steel pipes generally perform well in extreme weather conditions. They have high strength and durability, making them resistant to harsh weather elements such as extreme temperatures, heavy rainfall, and strong winds. The material's resistance to corrosion and rust also ensures that the pipes can withstand long-term exposure to moisture and other environmental factors. However, it is important to note that proper maintenance and protective coatings can further enhance their performance and lifespan in extreme weather conditions.

- Q: How do you calculate the pipe pressure drop for steel pipes?

- To determine the pressure drop in steel pipes, there are two equations that can be utilized: the Darcy-Weisbach equation and the Hazen-Williams equation. The Darcy-Weisbach equation, although more precise, necessitates a greater amount of information. It takes into consideration the diameter, length, roughness, fluid flow rate, as well as fluid properties like viscosity and density. The equation is expressed as: To calculate the pressure drop (ΔP), the following formula can be used: (f * L * ρ * V^2) / (2 * D) In this formula: - ΔP denotes the pressure drop - f represents the friction factor (which can be determined using Moody's chart or empirical equations such as the Colebrook-White equation) - L signifies the length of the pipe - ρ denotes the fluid density - V represents the fluid velocity - D signifies the pipe diameter On the other hand, the Hazen-Williams equation is a simplified version commonly employed for water flow calculations. Although less accurate, it is more user-friendly. The equation is expressed as: To calculate the pressure drop (ΔP), the following formula can be used: K * Q^1.85 / (C^1.85 * d^4.87) In this formula: - ΔP denotes the pressure drop - K signifies the Hazen-Williams coefficient (which relies on the pipe material and roughness) - Q represents the flow rate - C signifies the Hazen-Williams roughness coefficient - d denotes the pipe diameter It is crucial to note that these equations provide estimations of the pressure drop, and actual conditions may vary due to factors such as fittings, bends, and valves in the pipe system. Furthermore, consistency in unit usage (e.g., SI units or US customary units) is of utmost importance when employing these equations.

- Q: What are the typical lengths of steel pipes?

- The typical lengths of steel pipes can vary depending on their purpose and application. However, common lengths range from 20 feet (6 meters) to 40 feet (12 meters) in commercial and industrial settings.

- Q: Is the diameter of the steel tube indicated by the outer diameter by the wall thickness or by the inside diameter by the wall thickness?

- Seamless steel pipe specifications are: outer diameter, wall thickness, material. Three of these reflect its main features.Welding pipe specifications are: nominal diameter (internal diameter), galvanized or non plated

- Q: How are steel pipes used in the food and beverage industry?

- Steel pipes are commonly used in the food and beverage industry for various applications such as transporting liquids and gases, including water, beverages, and food ingredients. They are chosen for their durability, resistance to corrosion, and ability to maintain hygiene standards. Steel pipes are used to facilitate the flow of materials throughout the production process, ensuring safe and efficient operations in the food and beverage industry.

- Q: How are steel pipes used in the manufacturing of shipbuilding?

- Steel pipes are used in shipbuilding for various purposes such as constructing the ship's hull, piping systems for fuel and water transport, ventilation systems, and structural support. They provide strength, durability, and corrosion resistance, making them essential components in the construction and operation of ships.

- Q: What's the difference between a rectangular tube and a rectangular steel tube?

- No difference, but your name is different, rectangular steel pipe, but can be divided into seamless rectangular steel pipe and welded rectangular, these two, in the material will also have a difference, I do not know how to help you

- Q: Can steel pipes be used in the automotive industry?

- Yes, steel pipes can be used in the automotive industry. They are commonly used for various applications such as exhaust systems, fuel lines, and structural components due to their strength, durability, and resistance to heat and corrosion.

- Q: How are steel pipes protected against soil movement or settlement?

- Steel pipes can be protected against soil movement or settlement through the use of various measures such as proper design and installation techniques, including the use of appropriate bedding materials, backfilling with compacted soil, and the addition of protective coatings or linings. Additionally, the implementation of geotechnical investigations and monitoring systems can help identify potential soil movement or settlement issues in advance, allowing for proactive measures to be taken to mitigate any potential damage to the steel pipes.

Send your message to us

Rectangular Steel Pipe Production Serious

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords