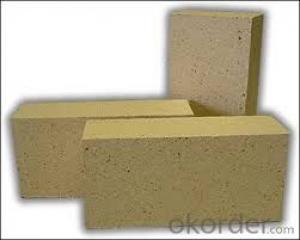

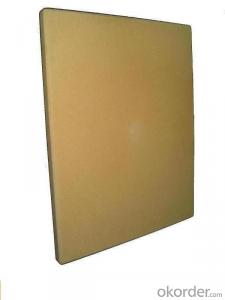

High Alumina Brick Rectangular Pizza Baking Stone for Cooking Pizzia

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1,Rectangular Pizza Baking Stone 300*400;

2,Color:Yellow/White;

3,Heat resistant;

4,Durable and Eco-friendly materials.

Special size/shape/color can be made according to your design/requirement.

Description Rectangular Pizza Baking Stone

Color Yellow

Dimensions 300*400mm

Ideal Thickness 12-15mm

Net Weight Approximately 2.8kg

Certification FDA,RoHS,LFGB

Our qualified baking stones are made of cordierite, which is eco-friendly and free of heavy metals, cadmium, lead as well as other harmful substance.

It can be used in either conventional oven,microwave oven,or directly on the fire.It's working temperature is 1000°c and it would not crack no matter how extremely change of the temperature.

It helps to distribute the heat of the oven evenly to your pizza and absorb excess moisture creating a crisper crust.

- Q: What is the difference between corundum and high alumina??

- The difference between them lies in the content of alumina and the alumina refractory products with alumina content higher than 48%The content of Al2O3 is higher than 90%, which is called corundum brick.

- Q: What are the requirements for Rubble backfill height?

- 1, filling thickness is not greater than 50cm.2, filling, the use of layered filling.

- Q: What's the difference between a well type annealing furnace and a box type annealing furnace?

- RT3 series trolley type resistance furnace is a national standard energy-saving cycle type operation furnace. It has super energy-saving structure, adopts fiber structure and saves electricity 30%. Exclusive production of composite high aluminum nails group, car anti-collision sealing brick, automatic sealing trolley and furnace door, integrated rail, without the basic installation, placed on the ground floor can be used. Mainly used for high chromium, high manganese steel castings, ductile iron, roller, steel ball, 45 steel, stainless steel quenching, annealing, aging, and various mechanical parts heat treatment. Features: 1, no noise, no environmental pollution. 2, small heat storage, less heat loss. 3, high temperature control accuracy, furnace temperature uniformity. 4, a high degree of automation, simple. 5, PID programming can be used to set, fully automatic operation. 6, good sealing, long life, safe and reliable. Widely used in chemical, petroleum, food, metallurgy, machinery, light industry, electricity, ships, paper, mining, medicine, central heating and other industrial sectors. With the development of social productive forces, its application in various industries is more and more widespread. Two, pitannealingfurnace (for example: flange heat treatment furnace) use: the furnace for metal parts, such as ring of equipment heat treatment at rated temperature: the furnace is composed of furnace body and a movable furnace cover and control system.

- Q: What are the alloy wear resistance materials?

- KNMn19Cr2 (patent) high manganese alloy (ZGMn13Cr2MoRe), super high manganese alloy (ZGMn18Cr2MoRe); two: anti-wear chromium cast iron series: such as high, medium and low chromium alloy cast iron (Cr15MOZCu); three: wear resistant alloy steel series: such as, low and high carbon multi metal combined steel (such as ZG40SiMnCrMO and ZG35Cr2MoNiRe); four: ADI (ADI) series; five: all kinds of composite or gradient material and hard alloy materials, nano KN alloy (patent product): such as chromium carbide composite (Cr2C3+Q235), high-energy ion osmosized tungsten carbide materials (WCSP), high toughness of cemented carbide (YK25.6), KN999 nano alloy (Beijing Naimo patent) etc.;

- Q: How to distinguish the good or bad of the high aluminum brick?

- In the procurement of high alumina brick, the first color, high quality aluminum brick, brick surface smooth, yellow color pale, four sides equal, no broken angle, no cracks.

- Q: What kind of material is the general metal case?

- Ordinary computer chassis and the material itself does not produce high-energy radiation, only in the space environment of the computer is the external defense requirements, and in the space structure, the use of lead as protective materials, unbearable weight.

- Q: What is the difference between metal compounds and metal solid solutions?

- Solid solution refers to the alloy phase in which the solute atoms are dissolved into the solvent lattice and remain solvent type. A crystalline substance consisting usually of atoms or molecules in which a chemical substance is dissolved as a base; other substances are found in alloys and silicate systems; also present in polyatomic substances. The mixture can be treated as a solution when the crystal structure of the solvent can be stabilized and homogeneous after addition of solute. Some mixtures can form solid solutions in many concentrations, while some mixtures do not form solid solutions at all.

- Q: How can the refractory brick blast furnace be pulverized and pulverized enough not to be taken away by the wind?

- Because the hot air outlet of the top burning hot blast furnace is high, the installation requirement of the hot air manifold is high, and the requirement of the strength of the pillar structure is higher, so the rectangular arrangement of the hot blast stove is arranged. The top burning hot blast stove is located on the furnace top because of burner and hot air valve,Therefore, operation, maintenance and installation all require mechanization and automation. Also, because these water cooled valves are mounted with a high elevation,Therefore, the demand for cooling water supply pressure should be improved accordingly, the use of large top burning hot blast stove, the key lies in the design of high-power high-efficiency short flame burner. The top combustion hot blast furnace absorbs the advantages of internal combustion and external combustion hot blast stoves, and overcomes some of their shortcomings,Its structure can meet the requirements of modern blast furnace for high temperature, high pressure and large scale development,Combustion capacity, while meeting production requirements, has been successfully reduced by many devices,

- Q: The difference between clay bricks and clay bricks

- Sintering bricks do not have clay bricks, so sintering bricks are made of stone. Clay brick is clay cooking, two yo, qualitative difference, but the appearance and color almost, but the quality is very different, life expectancy is also a great gap.

- Q: What are the categories of bricks?

- Ordinary brick size of 240 mm * 115 mm * 53 mm, according to compressive strength (Newton / square millimeter, N / mm2) size is divided into MU30, MU25, MU20, MU15, MU10, MU7.5, these intensity levels.

Send your message to us

High Alumina Brick Rectangular Pizza Baking Stone for Cooking Pizzia

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords