Rebar Threading Machines(Automatic Type)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Rebar Threading Machines(Automatic Type)

Model No. : S-50A,Compressor Clamp Head/S-50E Motor Clamp Head

Size: 150x80x120(LxWxH,cm)

Weight:S-50A,400Kgs;S-50E 450kgs

Item | S-50A/S-50E | |

Motor | kind of motor | Squirrel - Cage Induction Motors ( SCIM ) 3-PHASE |

Design Standards | IEC 60034, IEC 60072 | |

Voltages | 380V | |

Frequency | 50Hz or 60Hz | |

Output Range | 7.5KW | |

R.P.M. (Syn.) | 1440 min | |

Time Duty | Continuous. S1 , S.F.:1.0 . | |

Protection Enclosure | Totally Enclosed ( IP 55 ) . | |

Cooling Method | Self External Fan, Surface Cooling ( IC 411 ) . | |

Gear Speed Reducer | MODE | BWY |

Ratios | 1:19 | |

Lubricate | ISO EP68 Gear Oil | |

Cutter Head | Steel Bar Rang(mm) | 16-40mm |

Screw Max Length(cm) | 275px standard, 750px screw for Max 32mm Steel Bar | |

Cutting Lubrication | Coolant Circulation by Water Pump | |

Cutter Using times | 6000-8000 times | |

Clamp Head | Clamp head Driven | S-50A by Air/S-50E by motor |

Accessories | Emergency Stop Bottom | |

Air Compressor 0.6/min and Air Tube for S50A for 4 Nos machine | ||

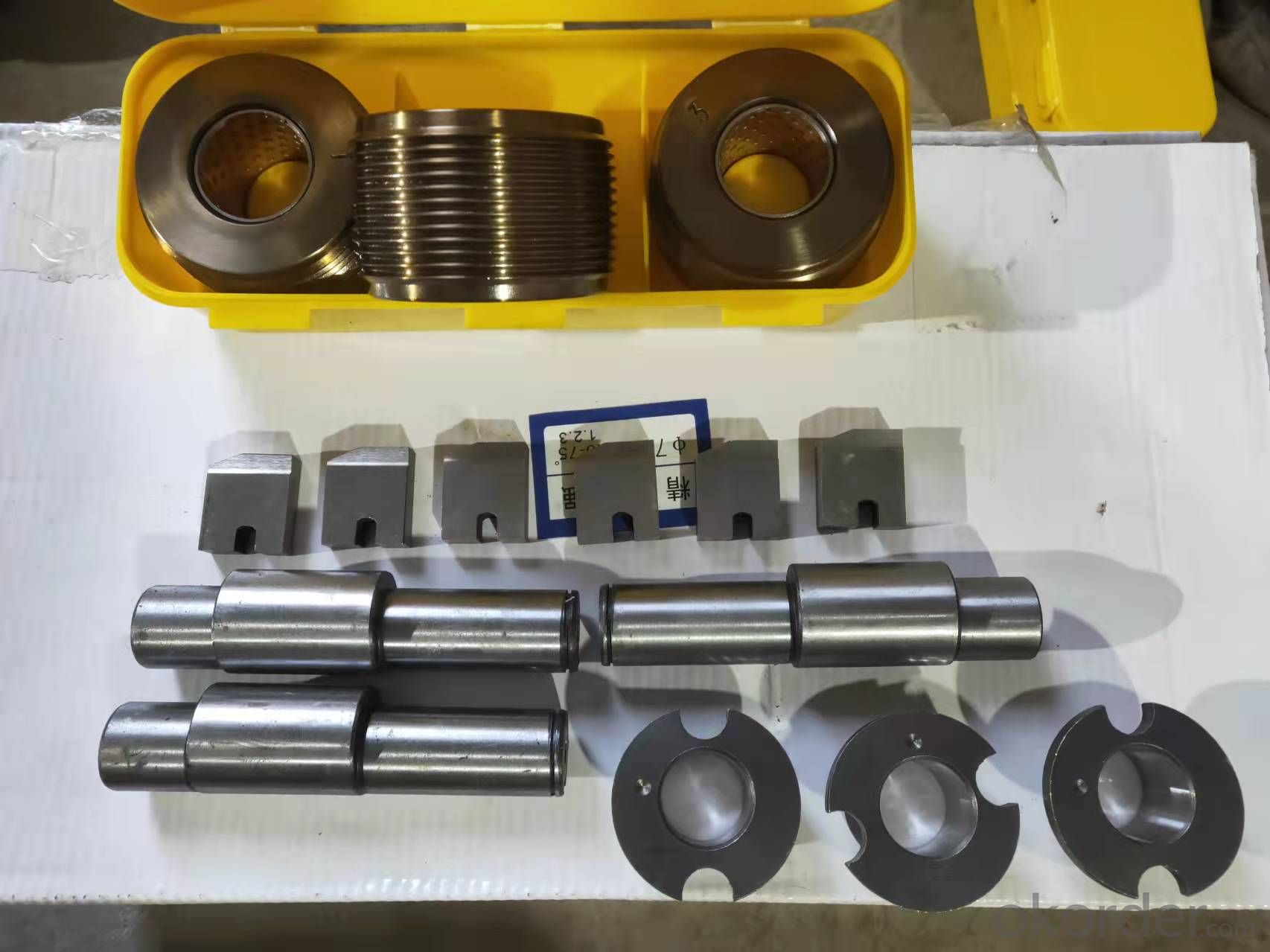

Consumption Parts | Part No-001 | Die-head Threading,6000-80000 times |

Part No-002 | Rib Removing Cutter,3000-4000 times | |

Part No-003 | Eccentric Shaft,Each half year | |

Reducer Lubrication Instruction:

Check and fill the lubricate before running the machine, first lubricate maintenance after 300 hours running and 1000 hours or half year after first lubricate maintenance.

Lubricate oil:ISO EP68 or 150 Gear oil, 1.5 Liter

Please check before running the machine , no any lubricate oil filled by the manufacturer for safety delivery purpose.

- Q: The difference between a power cell and an energy storage battery and an electric tool battery

- Batteries for power tools are mainly batteries used in power tools. The battery powered tools without wire supply are the first to use nickel cadmium batteries as the power source. With the development of battery manufacturing technology, lithium battery is the main current.

- Q: What are the motors that are often used in hand held electric tools?

- Considerations for hand held electric tools:Before the tool is used, the electrician shall check whether the wiring is correct and prevent the connection of the zero line and the phase line.Tools that are left unused or wetted for a long time should be checked by electrical engineer before use. Does the insulation resistance meet the requirements?.The soft cable or cord that comes with the tool can not be connected long, and when the power is away from the work place, it should be solved by mobile electric box.The original plug of the utility model can not be dismantled or changed at will, and the metal wire of the electric wire is directly inserted into the socket without using the plug.Found the tool case, handle broken, should stop using, replace.Non - professional personnel shall not disassemble or repair tools without authorization.The rotating parts of hand tools should be protected;Operators are required to wear insulation protection products;Leakage protector must be installed at the power supply.

- Q: What power tools are available for air conditioning? Quick drilling

- The new house is best to play well, so as not to damage the wall later.The so-called "hole opener" is what we usually say "diamond". It is need to add water to drill, drill out good effect not beautiful, but the device itself is reuse many times requires two people to complete cooperation, because of limited speed, in alignment to drill the position slowly pushed on it, but once found feel barrier when to stop, or slowly pull back again.

- Q: Know the power tool type and how to find the corresponding carbon brush

- Because most electric tool is the copy of foreign or domestic large and well-known brand products, such as Japan's MAKITA 4100 stone cutting machine with 303 carbon brush, Zhejiang 100 angle grinder with 51 carbon brush, 26 hammer with 21 brushes, just look for is the imitation of the machine, with the original machine manufacturers to see there is a Book brush type in the above, a model to sell electric tool shop, or ask sell electric tools, all know, remember do not buy too cheap, cheap ordinary machine if you just, if imported or domestic good machine, or more than 1000 watts of power to machine. With the original or high quality, because the brush has a direct impact on the rotor (or motor) life

- Q: How to connect the sleeve head and the power tool?

- The sleeve head is normally used for an electric wrench, and the electric wrench is connected with a common hole of the sleeve head, and the socket head of different sizes can be changed at any time.

- Q: What are class DC power tools?

- The power tool has no battery pack, powered by a DC adapter, such as some DC screwdriver; or, 12V or 24V, powered by a cigar lighter in the car. (for example, car impact wrenches)

- Q: What kind of butter does the power tool use?

- The main performance requirements of electric tools grease, high temperature resistance, low temperature resistance, durability, water resistance and impact load.

- Q: Woodworking, DIY power tools, curve saws and circular saws, which is more practical?

- Their use is different, can not be replaced, the curve saw is mainly cutting arc, cutting straight line can also, but the performance is too bad, electric circular saws are mainly cutting wood, wood side, sticks, etc., convenient and quick. It's not what a curve saw can do.

- Q: How does the power tool gear select the lubricant?

- Lubricating oil is used in all types of vehicles, machinery and equipment in order to reduce friction, protection machinery and processing of liquid or semi solid lubricant, lubrication, cooling, mainly to rust, cleaning, sealing and buffering effect.

- Q: Why should the power tools be powered off when the people leave?

- When the operator leaves the power tools, the power failure should be handled in time. 1, electric tools can save electric energy consumption; 2, to prevent misuse of non professional personnel, the accident harm to people, equipment; 3, prevent the sun and rain, caused by electrified equipment leakage, short-circuit or fire; 4, eliminate idle people out of curiosity, caused by electric shock accident.Safety in order to produce, production must be safe.

Send your message to us

Rebar Threading Machines(Automatic Type)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches